In e-mobility, the temperature of all system units needs to be constantly monitored. The high currents result in losses with a corresponding generation of heat arising, in particular, at contacts. TDK has now developed a special-purpose high-voltage resistant temperature sensor for connectors.

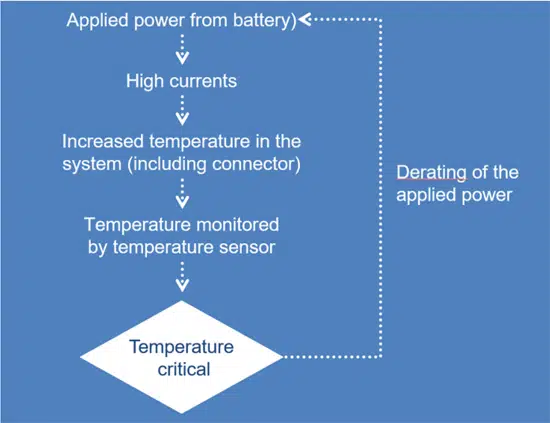

Today high-voltage batteries for electric vehicles (xEV) have rated voltages of up to 1000 V, necessitating all system components to be correspondingly high-voltage resistant. Currents in the three-digit bracket arise in achieving high drive power – some well over 100 kW – via inverter and motor. Together with line and contact resistances, these high currents result in substantial power dissipations and associated thermal losses since the currents are squared in the calculation: PV = I2 x R. This makes it clear that even slight resistances in the milliohm range produce relatively large losses and thus a possibly critical rise in temperature. If, for example, a contact point has a 10 mΩ resistance and is applied with a 100 A current, the result is a 100 W power dissipation which can quickly lead to overheating. That is why in xEV critical contact points – such as a connector between battery and motor inverter – must be thermally monitored and the current reduced in good time given imminent overheating. NTC-based temperature sensors which initiate current derating are suitable for monitoring the temperature at critical points. Figure 1 illustrates the control principle.

High requirements placed on NTC temperature sensors for xEV

E-mobility places completely different requirements on developing and designing NTC temperature sensors, especially for their integration into high volt systems. These include:

- High-voltage resistance

- Brief response time

- High-temperature stability

- High degree of precision

- Scope for direct integration into connectors

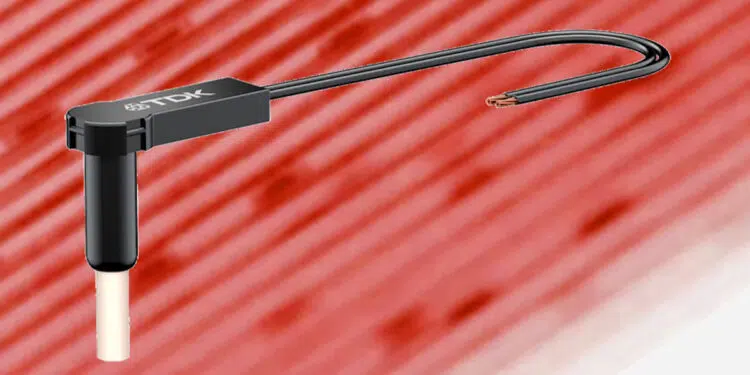

The challenge was finding a material with both a high electrical insulation property and, at the same time, excellent thermal conductivity and developing a design to integrate an NTC element. Furthermore, a high-temperature stability was to be provided. A special-purpose ceramic sleeve in which the sensor die is integrated proved to be suitable. Featured Image illustrates the temperature sensor developed in this way.

Innovative TDK temperature sensor meets all requirements

Multiple successful tests have proved that the newly-developed TDK temperature sensor meets the requirements placed on it. The high-voltage test produced a 5 kV DC dielectric strength of the sensor head – clearly well above the 1 kV DC system voltage. Also obtained was the required brief response time. It is particularly important for starting derating in good time given a case of sudden overheating. A τ-value (63%) of well under <10 s seconds was recorded in a typical installation situation. The permitted temperature range is -40 °C to +150 °C with brief 180 °C applications allowed.

Sensor precision is also an important aspect. Only when it is sufficiently high can derating be started not only in good time but also not too early on. At 25 °C, the new sensor has a maximum ±0.2 K deviation with the R25 resistance at 10 kΩ under a 1 percent tolerance.

The upper plastic section of the sensor is designed such that diverse customer fitting requirements, such as screw-on, clip-in or clip-on, can be implemented.

All in all, the effective electrical, thermal and mechanical values of the new sensor contribute to making electro-mobility safer and more efficient.