This Frenetic blog article from Sotiris Zorbas, MSc, Power Εlectronics Εngineer at Frenetic provides case study about 450V/12V flyback 10W transformer design to meet isolation and safety requirements.

The task is how to select the appropriate distances in a transformer design and decide exactly how much creepage and clearance is needed for the flyback design.

Lets explain the safety and isolation requirement on a 10W flyback transformer design for an auxiliary psu.

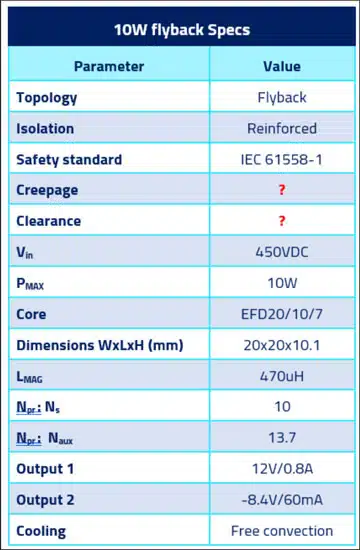

The input voltage in our case study will be 450V and the output 12/8.4V. This case study shares aspects of the actual design, starting with the spec sheet shown in Table 1.

Insulation Type Selection

The main insulation categories are

- functional

- basic

- reinforced (or double) insulation.

Functional insulation only accounts for a bare minimum insulation that can only guaranty functionality of the transformer. Basic insulation provides protection against fault conditions, such as overvoltage conditions at the primary transformer side. Reinforced isolation is the strictest option, providing maximum protection against fault conditions, making sure that isolation doesn’t break down from the primary to the secondary side.

For this design reinforced isolation was chosen.

Working Voltage

That is the maximum voltage that the insulation of the transformer can experience under normal operating conditions. In our case that’s about 450V between the primary winding and the secondaries.

Pollution Degree

The standard specifies different pollution degrees depending on the actual machine/product the transformer is used in. For example an epoxy potted transformer will always be clean, away from humidity and dust. But the most common thing is unpotted transformers that are subjected to dust humidity and other “pollutants”.

IEC 61558-1 defines pollution degree as below:

- Pollution degree 1: “Pollution degree in which no pollution or only dry, non-conductive pollution occurs.”

- Pollution degree 2: “pollution degree in which only non-conductive pollution occurs, except that occasionally a temporary conductivity caused by condensation is to be expected.”

- Pollution degree 3: “pollution degree in which conductive pollution occurs, or dry non-conductive pollution occurs which becomes conductive due to the condensation which is to be expected.”

Most times pollution degree 2 is chosen, as is the case with this design as well.

Overvoltage Category

That is a probabilistic categorization that hasn’t got to do with the transient voltages that a transformer will experience necessarily, but it’s rather a categorization depending on the application the transformer is used in.

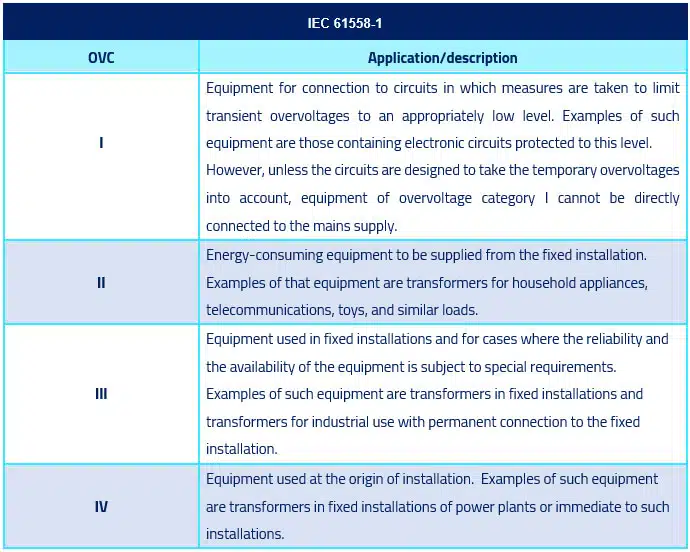

We have 4 overvoltage categories (OVCs) named I to IV. Take a look at Table 2 to understand the applications and description of each overvoltage category.

Overvoltage category II was appropriate here.

CTI Index

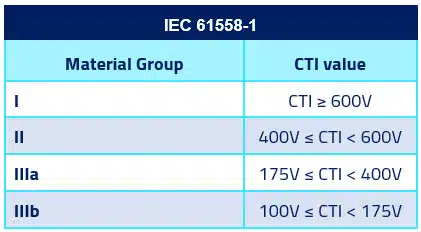

CTI index is the voltage which causes tracking after 50 drops of 0.1% ammonium chloride solution have fallen on the material.

The results of testing at 3 mm thickness are considered representative of the material’s performance in any thickness. Tracking is the breakdown of insulation on top of an insulator created from a voltage potential which gradually creates a carbonized conductive path along the surface, creating a leakage-conductive path.

When we talk about insulating materials we consider the bobbin, insulating tape between layers, margin tape and wire ending sheeves like heat shrink tubes.

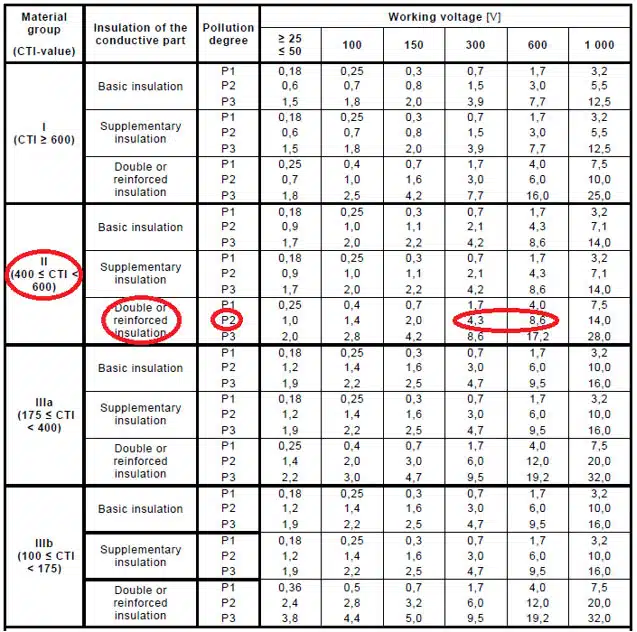

The cost effective/good compromise is to select material group II (400V ≤ CTI < 600V ) for all of the aforementioned components.

Finding the Minimum Clearance Distance

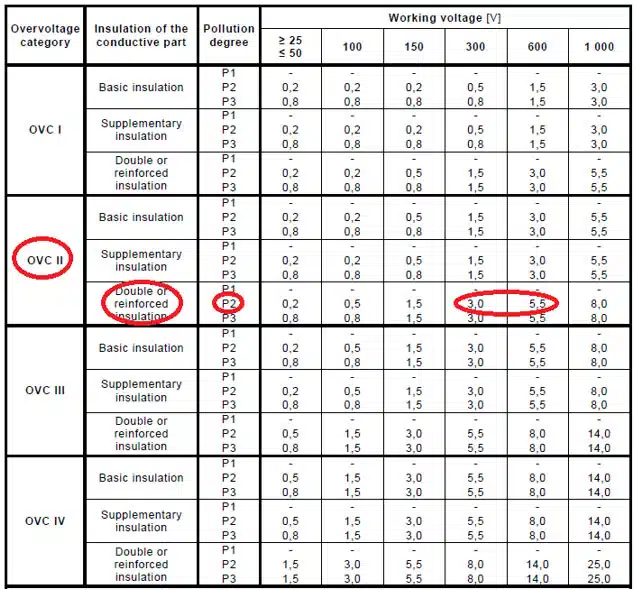

We have previously selected:

- OVC II

- Reinforced isolation

- Pollution degree 2

- Working voltage 450V

From IEC61558-1 in Table 4 we see that the necessary clearance is between 3-5.5mm. Although most standards allow linear interpolation between values in tables, for this table the standard forbids this. So the minimum clearance is 5.5mm.

Finding the Minimum Creepage Distance

We have previously selected:

- Material category II

- Reinforced isolation

- Pollution degree 2

- Working voltage 450V

From IEC61558-1 in Table 5 the necessary creepage is between 4.3-8.6mm. In this case linear interpolation between table values is permitted, thus 6.5mm of creepage distance is calculated for 450V.

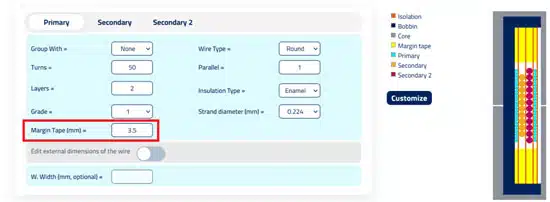

Margin Tape and Windings Picture

This design was built with margin tape. Using 3.5mm of margin tape on each layer the final creepage is set at 3.5×2=7mm, as shown in Figure 2.

Summary

Now you’re in the position to understand in more detail the way we comply with a safety standard. To be honest there are a lot more things that need to be taken care of to make sure the transformer complies, but this is a mayor step in this direction.

References

- (2018) Transformer Design Considerations. tech. Wurth Electronik. (Accessed: February 13, 2023).

- IEC 61558-1, Safety of transformers, reactors, power supply units and combinations thereof. part 1, General Requirements and tests (IEC 61558-1:2017) (2019).