This article based on Sotiris Zorbas, Power Εlectronics Εngineer Frenetic newsletter will guide you through the process of choosing ferrite cores from various manufacturers and then comparing them to select the ideal core material for a specific application.

Every Power Electronics Engineer is familiar with a couple or more manufacturers, depending on his location and degree of involvement in the field of Magnetics.

In Europe, for example, EPCOS, TDK and Ferroxcube are very popular names, thanks in part to the accessibility of their services through distributor channels like Digikey, Mouser, Farnell, TME. RS etc.

Why bother with other manufacturers?

Well, that’s an easy question: because of the price per core set and the availability when it comes to mass production. Indeed, there are some other reasons, like the tolerance with dimensions, which might be unacceptable in some designs. But really these are just exceptions.

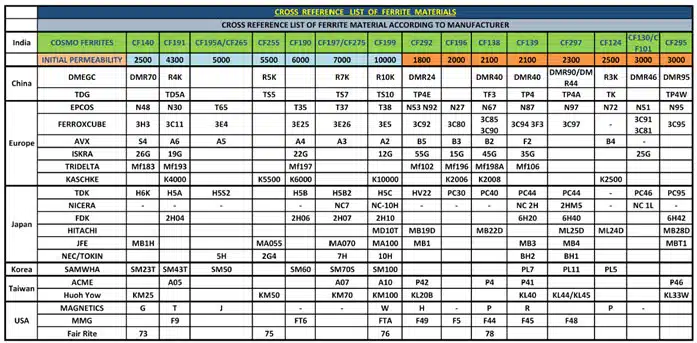

Figure 1 shows an easily available chart with part numbers of materials from different vendors that are compatible with each other. Keep in mind that this is an indicative graph, and should be treated as such.

How should I make an informed decision about the materials?

Begin by reaching out to the manufacturer that offers the most comprehensive information about their materials. For users with access to Frenetic Online, the Core Optimizer™ tool simplifies the process of comparing these options. Currently, we provide immediate support for Ferroxcube and TDK/EPCOS materials, and you also have the flexibility to manually include other materials as needed.

Let’s choose the least lossy material and we are done! Right?

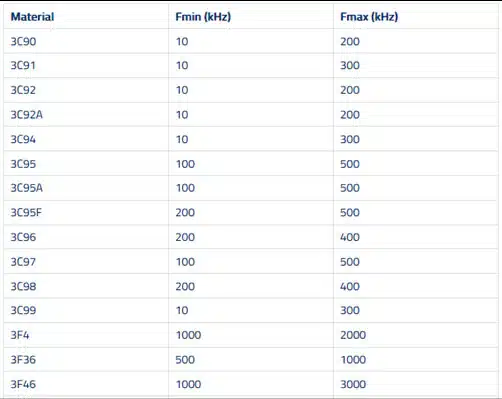

Well, if you’re conducting a quick and basic test, then I’m ok with it. However, for a more comprehensive evaluation, the first step should be selecting a material that aligns with the operating frequency of your Converter. And that’s quite an easy task. In Figure 2 you’ll find a list of commonly used materials along with their respective recommended operating frequency ranges.

Quickly comes the realization that for a 100kHz Converter most materials are compatible. However, employing a 3F36 core at this frequency is excessive and doesn’t justify the higher cost.

As far as frequency goes, we have given the “OK” to multiple materials. It’s important to note that, while multiple materials may align with the desired frequency range, they won’t necessarily exhibit similar core losses.

Core losses and core temperature

Here is the thing, when designing a Transformer/Inductor, we usually have a core loss target in mind. If you select a material, a constant frequency and fixed flux density swing, the only thing that will affect the core losses will be the core material temperature.

Imagine a Transformer in a DC/DC Converter. You “flip” the power switch and power get transferred to the load. The Magnetic component has some thermal mass, and it will take time to reach its final temperature. 30-120min are usually enough to reach a thermal equilibrium. So, the core is initially cold. Assume an initial ambient temperature of 25°C and a final temperature of 65°C for the core. At first, the core losses will be the maximum and, as the core heats up to its final temperature, the core losses will decrease, reaching a final value.

When trying to compare losses of different materials, a good option is to think about the final temperature of the component. Of course, that’s a rough estimate, but assuming the core is at 60-80°C will get you much closer to the final value than taking into account just ambient temperature.

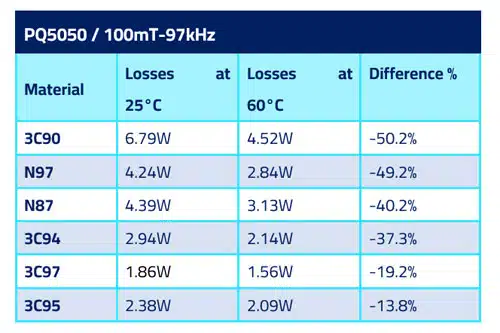

Table 1 provides insight into the impact of temperature on core losses across different materials. The materials are arranged from the most temperature-sensitive (3C90) to the least sensitive (3C95).

As much as 50% of core loss reduction can be observed between 25°C and 60°C for 3C90, and just 13.8% for 3C95. When looking at the power losses alone, 3C97 is the best performing material in the table.

A better approach

Next time you embark on a design, consider the impact of the target temperature under worst-case scenarios and choose the core losses accordingly. For instance, when working with a 3C94 material, aiming for a final Transformer/Inductor temperature range of 50-70°C allows for choosing approximately 35% more losses than the typical design. This can be achieved by adjusting the number of primary turns to control the operating flux swing. As the component heats up, the effect of temperature will lead to reduced core losses, bringing them closer to the initial target.