This article based on Knowles Precision Devices blog discusses how to specify capacitors for high-energy pulse applications.

Energy storage capacitor banks supply pulsed power in all manner of high-current applications, including shockless compression and fusion.

As the technology behind capacitor banks advances with more precise switching and higher energy density, fast discharge capacitors can reliably support more advanced applications.

The energy storage capacitors selected for large banks must feature low inductance, high peak current, strong fault tolerance and excellent reliability over their lifespan.

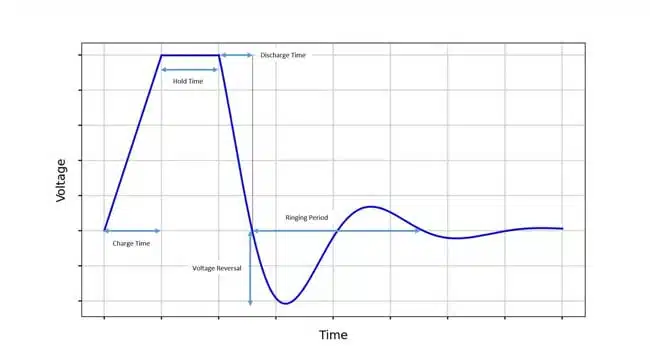

When working to specify high energy capacitors, consider the following charge, hold and discharge profile for a capacitor in an RLC circuit (Figure 1).

The following questions address crucial factors that influence capacitor performance, reliability and longevity in high-energy pulse applications. Answering them will help us ensure that you have the right capacitors for your design.

What capacitance and voltage conditions will your high energy capacitors be subjected to?

By definition, the energy stored in a charged capacitor is:

There are a few real-world factors that influence the mathematical relationship here. Depending on the charging method, achievable voltage varies. Further, capacitor discharge is never 100 percent efficient. Knowles Precision Devices is prepared to discuss your energy storage goals and help you establish capacitance and charging voltage targets.

What’s your strategy for capacitor charging?

Considering the amount of energy at play, power supply choice is an important design parameter. Regardless of the charging mode (e.g., constant voltage, constant current, constant power or resonant charging), shorter charge time is favorable to avoid prefiring. Figure 1 shows constant current charging time as the first stage in the hold and discharge profile.

How long do you need the capacitor to hold its charge?

The second stage in the hold and discharge profile, shown in Figure 1, is the hold time. Account for this period in your design process as excessive hold times impact overall safety and reliability.

How quickly must the capacitor bank discharge its energy into the circuit?

Discharge time is determined by RLC circuit parameters, so share as much as you can about the circuit the capacitor bank will discharge into.

What is the expected ringing period, if any?

The damping of the RLC circuit your capacitor bank is discharging into may cause voltage ringing. Share if you have specific design criteria around the ringing period.

What is the expected voltage reversal?

The expected voltage reversal is the reverse peak voltage that occurs during the pulse discharge process of the capacitor. Reversal happens due to the parasitic inductance in the circuit, which causes energy to oscillate between the capacitance and inductance. The oscillation causes a reverse voltage and current to briefly appear across the capacitor, such that it’s measurable at each pulse. Capacitors have different rated tolerances for reverse voltage.

What is the desired shot life?

Shot life, expressed as a percentage of survival probability, indicates the number of charge/discharge cycles that a capacitor can endure before failure. Capacitor lifespan depends on factors like the percentage voltage reversal, ringing frequency, temperature and operating voltage. Knowles Precision Devices offers statistical analyses to understand capacitor survival rates in context.

What is the target pulse repetition rate?

The target pulse repetition rate should be set to achieve a reasonable shot life for the capacitor. In addition to selecting materials with high dielectric strength and low loss, depending on the target rate, specialized cooling methods might be needed for heat dissipation and mechanical reinforcement.

In addition to a thorough understanding of the specs detailed here, it’s important to consider your form factor, as it imposes additional size constraints on capacitor selection.