In this blog article Pablo Blázquez, Frenetic Power Εlectronics Εngineer is exploring a key element in Transformer design: the leakage inductance!

Leakage Inductance

Leakage inductance is produced by the imperfect magnetic coupling between the transformer windings. The magnetic flux generated in the primary winding is never transferred 100% to the secondary winding. Its magnitude plays a key role in modern switched-mode power supplies. Whether it needs to be minimized or maximized, the use of complex prediction models, which are many times far from reality, is required.

In cases where higher leakage inductance is required, a magnetic shunt can be inserted between layers, while another possibility would be the use of fractional turns.

Leakage inductance depends on:

- Winding geometry.

- Core geometry.

- Number of turns.

Due to the fact that the winding geometry and arrangement have a high influence on the leakage inductance, it gets really complicated to calculate it analytically and get reliable results. However, if you know the effect these parameters have on the leakage, you will be able to control it.

How to Reduce it?

Here are some solutions to reduce the leakage inductance:

- Decreasing the number of turns and layers.

- Reducing the insulator layer thickness.

- Using the interleaving arrangement.

- Lowering the mean turn length.

- Increasing the core window width.

- Decreasing the core window height.

The reduction of the leakage inductance is fundamental to obtain better power efficiency, but it goes at the expense of other parameters. For example, reducing the number of turns will also produce higher core losses. On the other hand, it is important to bear in mind the relationship between leakage inductance and parasitic capacitance: lower leakage inductances will lead to higher capacitances (C1= 1/w2 lk1).

In other cases, where higher leakage inductance is required, a magnetic shunt can be inserted between layers. Yet another possibility would be the use of fractional turns.

Experimental Results

Let’s analyse now several case studies with a focus on the leakage inductance. By changing the construction of our transformer and transformer topology, we’ll see what are the effects induced on the leakage inductance value.

Case Study 1: change construction parameters

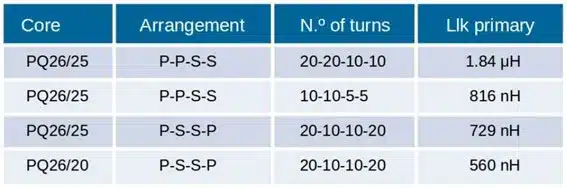

In this experiment we can see how different cores, winding arrangement and number of turns, while keeping the turns ratio constant, influence the leakage inductance values:

- Experiment 1: PQ26/25 transformer with a turns ratio of 2:1.

- Experiment 2: PQ26/25 transformer with a turns ratio of 2:1 but the number of turns is half than in experiment 1.

- Experiment 3: PQ26/25 transformer with a turns ratio of 2:1 and P-S-S-P arrangement.

- Experiment 4: PQ26/20 transformer with a turns ratio of 2:1 and a P-S-S-P arrangement.

The results are summarized in Figure 1. Table.

For experiments 1 and 2 show how the reduction of the number of turns leads to a consequent decrease in the leakage inductance.

Comparing experiments 1 and 3, it is clear how the leakage changes when the primary and secondary wires are alternated. Experiments 3 and 4 show the effect of the change in the height of the window: higher core windows will have higher leakage inductances.

Case Study 2: influence of the winding arrangement in different topologies

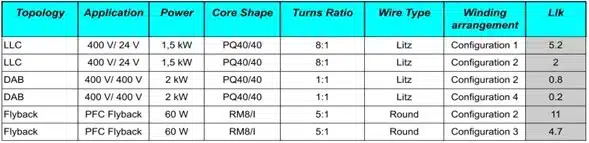

Let’s change now the winding arrangement in different topologies and see the effect of the leakage inductance.

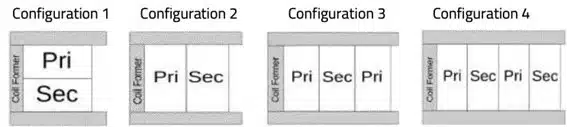

Values of leakage inductance will be measured for different converters with four different winding configurations – see Figure 2., from the high-pot winding arrangement (Conf. 1) to two layers interleaving arrangement (Conf. 4) passing through simple P-S configuration (Conf. 2) and simple interleaving (Conf. 3).

Table 1 shows the Converters used for this experiment for each topology with different winding configurations. Results demonstrate how the smaller the difference between primary and secondary turns, and the better the interleaving arrangement, the smaller the leakage inductance achieved.

Case Study 2: Experiment 1

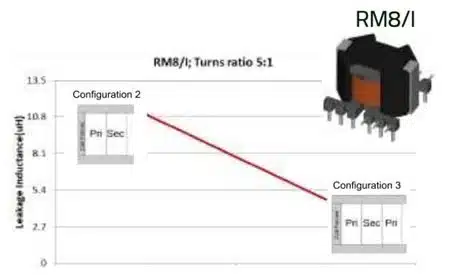

Figure 3 shows how the leakage inductance is reduced by 50% from Conf. 1 to Conf. 3 in an RM8/I. The more the winding is interleaved, the lower the leakage.

Minimization of the leakage inductance in flyback Converters is generally a must, otherwise high voltage spikes at the switching node would be present with the increased stress that this involves in the semiconductors. The interleaved planar Transformer could be used in this case, but taking a special care of the parasitic capacitance that will create a path for common-mode noise.

Case Study 2: Experiment 2

In experiment 2, we used a PQ40/40 with a turn ratio of 1:1. The Llk is reduced by a factor of 4. The decrease in the leakage inductance appears as a consequence of the division of the winding on a higher number of layers with interleaving arrangement, from P-S to P-S-P-S arrangement.

Case Study 2: Experiment 3

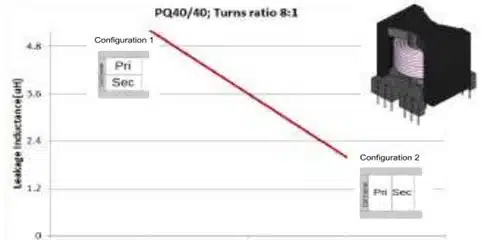

Experiment 3 in Figure 4. uses the same core shape as in case 2, but with 8 times higher turns ratio (8:1). Winding Conf. 1 and 2 do not seem very different, however, as we can see in the results, the Llk is reduced 2.6 times, from 5.2 to 2 uH.

Compared to experiment 2, it seems to have lower Llk change. But talking in absolute values, it has a higher impact, as in experiment 2 the leakage is reduced 0.6 uH, and in experiment 7 is of 3.2 uH.

Conclusions

Knowing the leakage inductance in advance can give you an idea of the total efficiency of the magnetic component before manufacturing it. Theoretical calculations can give you an approach to the leakage inductance of a planar Transformer, but calculations become much harder and less accurate when it is not a planar.

Here is what I’ve learned from this experiment:

- When turns ratio is closer to 1, we have better coupling between windings and leakage below 1uH.

- Winding arrangement has a great influence on leakage results.

- Knowing the leakage value can help you create more efficient designs.

By using Frenetic you can get accurate results of the leakage inductance in your design in a matter of seconds. This will help you further optimize your design and reduce the time you need for designing magnetics.