KnowlesCapacitors blog explains insertion loss and performance in EMI filtering in article by Peter Mathews.

To comply with international legislation such as the EU Directive on EMC or the FCC, EMI filtering is an essential element of equipment design. Here, we will continue to explore EMI filtering through insertion loss and filtering performance.

The insertion loss performance shows signal attenuation at any given frequency. As a metric, the insertion loss performance is most useful as a guide in the filter selection process; the actual performance in service can vary depending on circuit characteristics.

Insertion loss is determined by the following factors:

- Electrical configuration

- Source/load impedances

- Load current

- Ceramic dielectric materials

- Earthing impedance

- Shielding integrity

Electrical Configuration

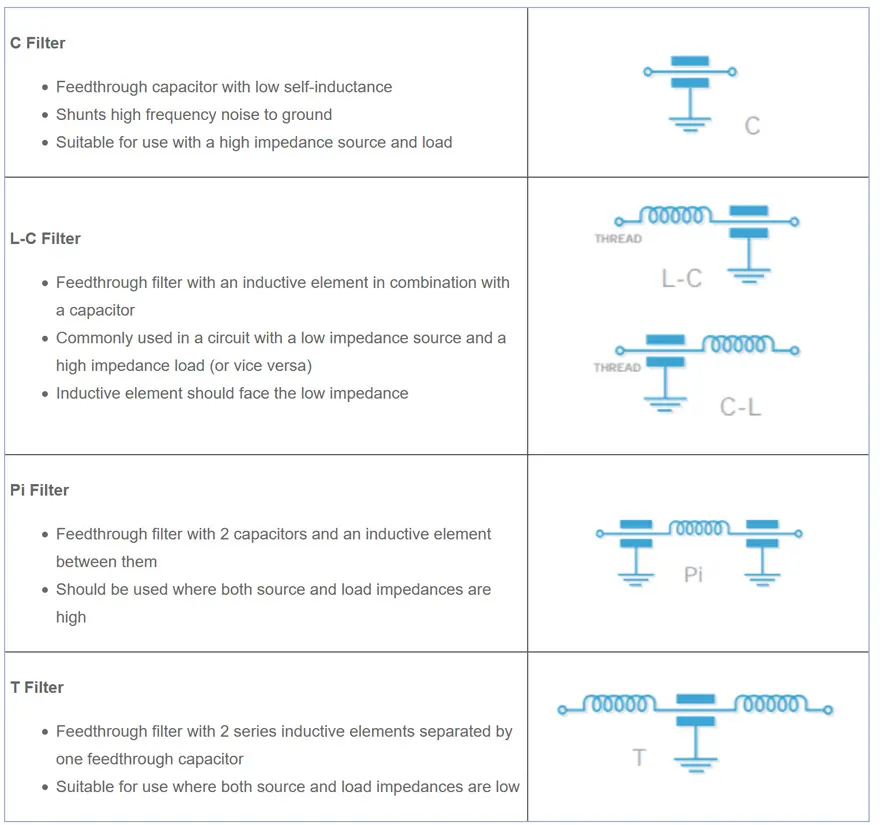

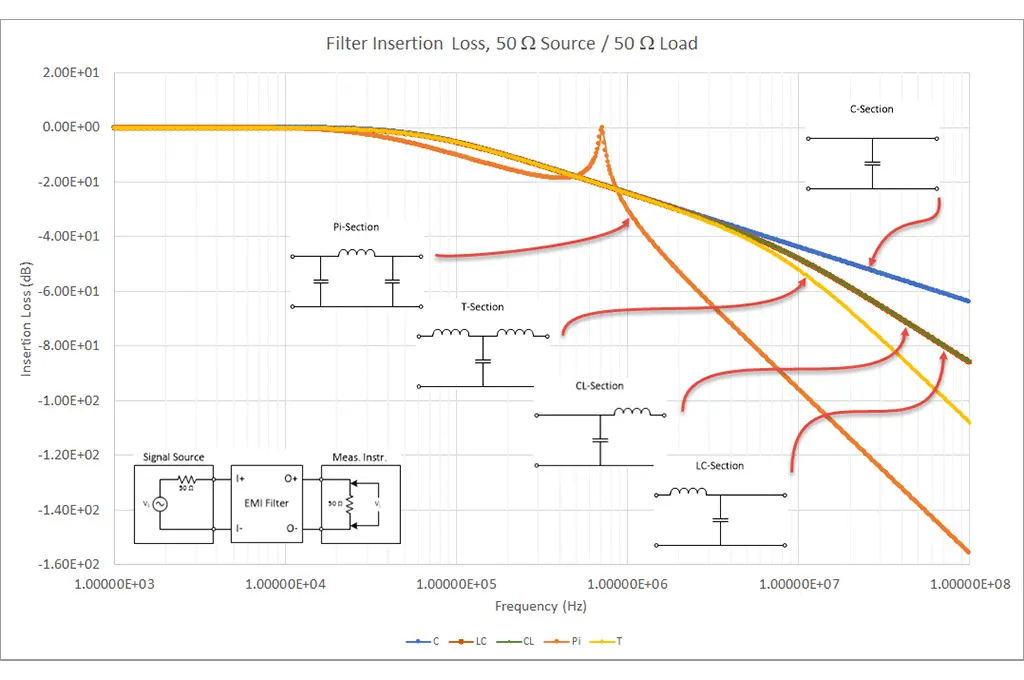

The choice of electrical configuration for a filter (the capacitor/inductor combination) primarily depends on the source and load impedances. Insertion loss figures are normally published for a 50Ω source and 50Ω load circuit. Impedance, in reality, will probably be different than the figures imply and could cause an increase or decrease in insertion loss. The electrical configuration of the filter should be chosen to optimize the filter performance for a specific source/load impedance scenario.

Common types of electrical configurations available in feedthrough filters include:

Multi-Element Filter

Contains more than 3 elements, for example L-C-L-C-L filters (addition of further elements increases the steepness of the insertion loss curve)

Load Current

The effect of load current on insertion loss is largely determined by the properties of the filtering elements used. For filtering circuits with inductive elements, insertion loss might experience a significant reduction where ferrite inductors are used; ferrite material saturates with current. Reduction in insertion loss depends on the current and the characteristics of the particular ferrite material. In extreme cases, the ferrite will become ineffective and insertion loss will appear to be the same as for a C filter.

Choosing a Filter

When selecting a filter, electrical configuration, physical implementation, and material (i.e. dielectric type) are all important considerations. The attenuation curve, shown in Figure 1, charts the various physical implementations of the electrical configurations detailed above. You’ll notice a simple chip filter provides the least attenuation at high frequency. Looking at either of these characteristics individually could be misleading in your selection process.

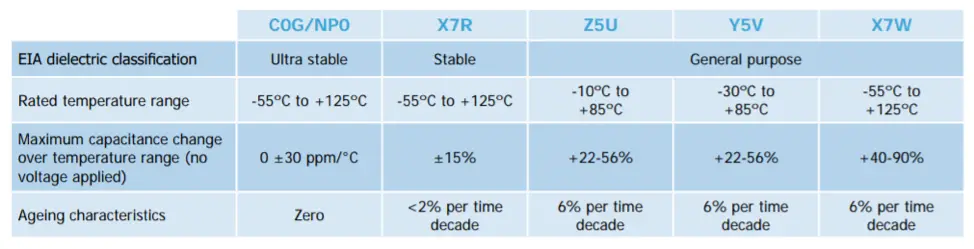

Looking, again, at the component itself, different categories of ceramic materials have different performance characteristics. For instance, as the dielectric constant increases (and therefore filter capacitance value increases), stability deteriorates. Specific operational and environmental parameters—including temperature, voltage, frequency, and time (aging)—can affect the dielectric constant.

As summarized in Figure 2, the three main classifications of ceramic dielectric employed in the manufacture of EMI filters are generally referred to as ultra stable (C0G/NP0), stable (X7R) and general purpose (Z5U, Y5V or X7W).

| C0G/NP0 – Ultra Stable | Most material parameters remain unaffected by temperature, voltage, frequency or time Stabilities are measured in terms of parts per million but dielectric constants are relatively low (10 to 100) |

| X7R – Stable | Material parameters are relatively stable with respect to temperature, voltage, frequency and time Typical dielectric constants would be of the order 2,000 to 4,000, enabling far higher capacitance values for a given size of capacitor than can be gained from C0G/NP0 materials If the voltage coefficient (VC) is critical, Knowles Precision Devices can also support parts with BX (2X1) and BZ (2C1) VC characteristics |

| Z5U/Y5V/X7W – General Purpose | Material parameters are severely restricted and performance under applied voltage may be seriously compromised Note: Knowles Precision Devices uses only the higher performance C0G/NP0 and X7R in its standard ranges |

Spread of Capacitance Values

The capacitance of a ceramic capacitor also changes as a result of varying temperature, applied voltage, and age. The final capacitance can fall within a range of values depending on material type and characteristics referenced in Figure 2. That said, if capacitance has reduced, so will the insertion loss performance.

featured image source: KnowlesCapacitors feedthrough