Nanocrystals are crystals measuring less than 100 nanometers in at least one dimension. The smallest fundamental component of a nanocrystal is called the crystallite, or grain. Materials that have nanocrystals distributed throughout, and have significantly different characteristics as a result, are called nanocrystalline materials. Semiconductor nanocrystals with dimensions smaller than 10 nm are also sometimes called quantum dots.

Nanocrystalline materials have many unique and useful properties. The unique mechanical, chemical, electrical, and quantum properties of nanocrystalline materials have driven a great deal of technological advancement in recent decades, and appear poised to drive even more in the years to come.

What are metallic nanocrystals?

In magnetics, “soft” describes a magnetic material with a low coercivity, i.e., an alloy created by crystallizing an Fe-based amorphous soft magnetic alloy. In this material, nanocrystal grains are dispersed quite evenly throughout the amorphous (or non-crystalized) phase. This material is ferromagnetic at room temperature, and in conjunction with the nanocrystals, realizes a low saturation magnetostriction constant, making it a very magnetically soft material.

This material was primarily used in choke coils and transformers for power electronics because of its excellent characteristics compared to conventional magnetic materials. Those excellent characteristics permit components constructed with it to be significantly reduced in size.

How are nanocrystals different?

Nanocrystalline soft magnetic cores are manufactured by casting the molten metal into a thin solid ribbon and then rapidly cooling it. A highly controlled annealing process is then employed to create a uniform and very fine nanocrystalline microstructure with grain sizes of ~10 nm. This process creates a high-performance EMI solution, but the thin metal ribbons wound together are easily damaged by shock or vibration.

To avoid damage, the core can be mounted in a core case, or even glued to the case, or the wound core can be impregnated with varnish to improve the vibration performance, to effectively protect the final product from vibration damage.

What are the advantages of nanocrystals?

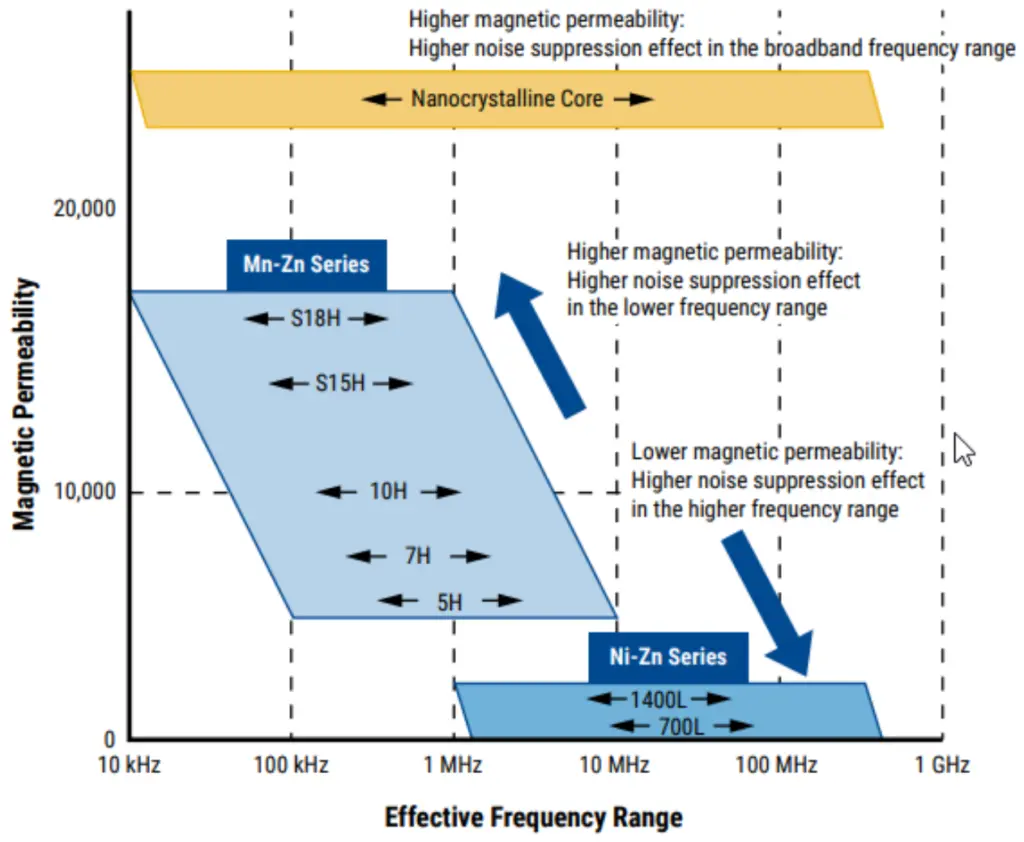

Compared to ferrite cores, the impedance of nanocrystalline cores is extremely high and the effective frequency band is very wide. This allows components to be made smaller and saves engineering time that otherwise would be needed to design and test other EMI countermeasures. Nanocrystal cores are, therefore, ideal for designs with complex EMI noise scenarios – high energy noise and/or noise at multiple different frequencies. In simple scenarios, where the noise energy is small or localized at one frequency, inexpensive ferrite cores are usually sufficient.

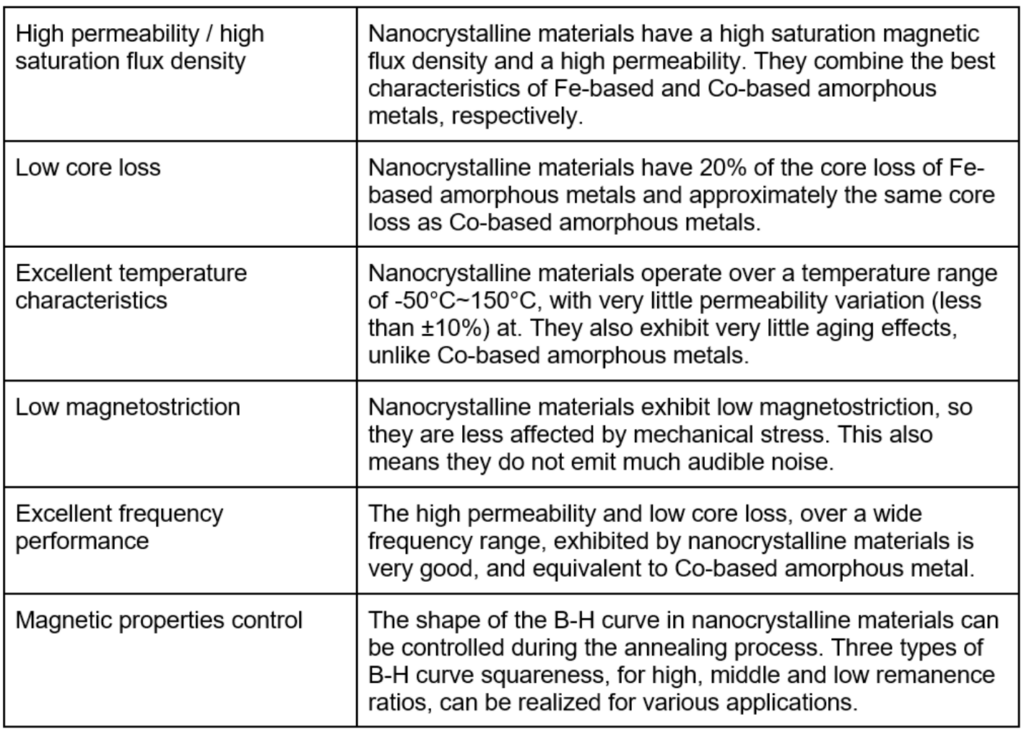

The following table summarizes the benefits of nanocrystalline soft magnetic material.

What are the ideal applications of nanocrystals?

Ideal applications for nanocrystal ferromagnets include high current output inverter devices. At high currents, the winding diameter becomes thicker, which limits the number of turns, and high inductance cannot be obtained, resulting in insufficient attenuation on the low frequency side. Nanocrystalline materials are a much better choice for these applications. As a result, an increasing number of Tier 1 automotive suppliers are also using nanocrystal cores in automotive units that require EMI protection in the CISPR band.

However, since nanocrystal materials pass magnetic flux well, saturation due to common mode current is likely to occur. In such cases, a coil using a ferrite material such as 5HT or 7HT, which does not have a very high magnetic permeability and has a relatively high magnetic flux density will be effective.

Other applications that are ideal for nanocrystal materials include:

- EMI filters / common mode chokes

- Current sensors / magnetic sensors