This article introduces magnetic fusion technology based on Heraeus Conamic article that supplied the qualified raw material for the initial test windows of this technology.

Introduction

Nuclear fusion through magnetic confinement: Sounds highly theoretical, but has the potential to provide us an almost limitless energy source in the future. Similar to laser fusion, magnetic fusion has recently achieved a major success: The world’s largest fusion facility called JET (Joint European Torus) in Culham, UK, generated 59 megajoules of energy in a period of 5 seconds at the end of 2021 – the highest ever achieved in such an experiment.

For the past 10 years, Heraeus Conamic has been in contact with the scientific team there, working together to define the specifications of the vacuum and inspection windows in the reactor for controlling the fusion process. This means that a small viewing window can have a significant impact on future alternative energy generation.

The magnetic fusion technology is currently the most pursued approach internationally. It is considered by the scientific community as more advanced and promising than laser fusion. The JET (Joint European Torus) team at Culham Centre for Fusion Energy (CCFE) is essentially carrying out preliminary work for the much larger experimental nuclear fusion reactor ITER (International Thermonuclear Experimental Reactor) in Cadarache, southern France. However, due to global economic uncertainties, the planned completion of ITER in 2035 has been delayed. “It was therefore even more important that the team at CCFE, with whom we collaborate, achieved this major milestone in the journey towards energy generation through magnetic fusion,” states Dr. Frank Nürnberg, Global Head of Sales Optics at Heraeus Conamic, expressing his utmost delight.

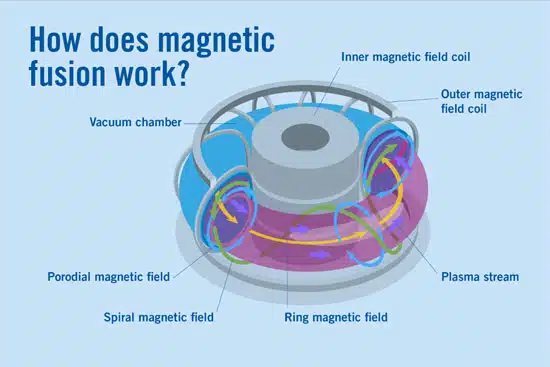

Magnetic field instead of laser beams

In laser fusion, individual atomic nuclei of the hydrogen isotopes deuterium and tritium are compressed and brought together to fuse through laser generated secondary radiation. This method is expected to generate multiple times more energy compared to the input. Magnet fusion aims to achieve the same outcome but through magnetic compression. Ring-shaped magnetic fields confine the fusion plasma composed out of the two isotopes, causing it to heat up to an unimaginable temperature of around 100 million degrees Celsius for ignition. Unlike a massive laser system spanning the size of three football fields with numerous fused silica optics, this fusion facility has transformed into a large donut-shaped vacuum chamber, with a diameter of approximately 19 meters in the case of ITER. The challenge now lies in sustaining the fusion process continuously. In the mentioned JET experiment, this lasted for about five seconds. Achieving this requires the complex control of the fusion process in the large vacuum chamber and exact reactor control respectively. Heraeus is contributing a small but significant role to this challenge by providing fused silica for windows in the vacuum chamber.

A view into the sun fire

The location of the fusion within the reactor needs to be continuously monitored, including spectroscopic analysis in the ultraviolet and near-infrared wavelength range. This is made possible through small viewing windows called ports in the outer shell. The glass for these windows requires certain characteristics for viewing the fusion process: extreme material strength, temperature and radiation resistance, and high transmittance across a wide wavelength range. Synthetic fused silica is the solution. “The environmental conditions in magnetic fusion are challenging for optical materials. Our fused silicas Suprasil and Spectrosil have been qualified for this task based on years of experience and measurement results in scientific applications with high radiation exposure,” explains Dr. Nürnberg. Therefore, it was not surprising that in 2023, Heraeus Conamic supplied the qualified raw material for the initial test windows.

Germany, along with other European countries, holds a leading position in magnetic fusion research. For example, the Max Planck Institute for Plasma Physics operates research facilities such as ASDEX and Wendelstein 7-. From this research environment, Proxima Fusion has already emerged as a spin-out. Additionally, Gauss Fusion, another start-up in the field of magnetic fusion commercialization, is located not far from the Heraeus headquarters in Hanau. There is progress in magnetic fusion, even though the major breakthrough is still pending. For Dr. Nürnberg, this is no reason for pessimism: “If Cosmonaut dog Laika had not been sent into space in the 1950s, we would not be planning the journey to Mars now. I see the same with the developments in magnetic and laser fusion, especially regarding the realistic possibility of another green energy source for our future. Therefore, Heraeus Conamic is very pleased to be able to support both technologies by providing high-quality fused silica.”