source: Panasonic article

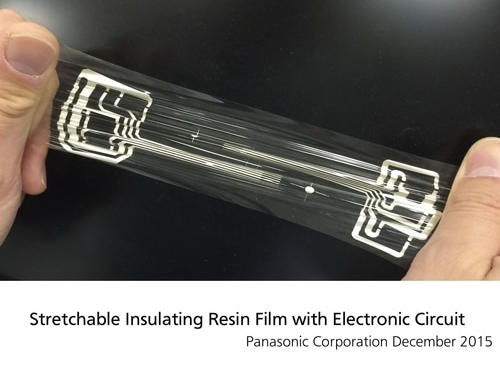

Osaka, Japan – Panasonic Corporation announced today that the company has developed a soft, flexible, and stretchable polymer resin film using its proprietary stretchable resin technology. The Company will also provide a transparent electrode material and conductive paste along with this insulating film.

This newly developed material is an insulating film material that stretches and returns to its original shape, a feature that is hard to find in conventional flexible materials. It adapts to desired manners of folding and to varying free-form surfaces, substantially reducing existing design constraints. For example, it enables the construction of soft and stretchable electronic devices that are adaptable to a variety of forms, such as of clothing and the body. The newly developed material is deployable in a broad range of applications, from wearable devices to sensors, displays, and robots.

The stretchable resin film offers the following features developed on the basis of the Company’s proprietary stretchable resin technology.

1. Soft and stretchable insulating film material that comes with excellent elasticity

■ Tensile elongation: x 2.5 or more

2. Insulating film material capable of relaxing internal stresses arising from stretch, returning to its original shape, and withstanding repeated use

■ Percentage of stress relaxation: 60%*1

■ Recovery rate: 98% or more*2

3. Additional development of a stretchable transparent electrode material and conductive paste along with the insulating material

*1 Results of in-house stress relaxation test (Conditions: 50% stretch for 30 min)

*2 Results of in-house stretch-recovery test (Conditions: 25 mm/min stretch rate and 0.1 mm/min recovery rate)

Features in Detail

1. Soft and stretchable insulating film material that comes with excellent elasticity

Against the backdrop of the development of various wearable devices, there is a growing demand for reduced odd feel from wearing them and more aesthetically pleasing design, as well as for a smaller size and thinner profile. Polyurethane and rubber materials need to overcome challenges associated with adhesion, heat resistance, and embrittlement. Demand is high for a conformable material that is excellent in terms of heat resistance, durability, and workability. Noting the proven performance of conventionally used thermosetting resin and applying the Company’s proprietary resin design technology that can add superb elasticity to the material, Panasonic has developed an insulating material made of thermosetting resin, which is, surprisingly, flexible and stretchable. This soft and stretchable insulating film material helps realize electronic devices for wearing or installation at desired locations.

2. Insulating film material capable of relaxing internal stresses arising from stretch, returning to its original shape, and withstanding repeated use

Devices implemented on clothing or worn on the body should be made of materials that withstand repeated use and allow no change in mechanical properties even after repeated deformation (stretch and restore). Generally, materials subjected to repeated stretch and restore would tend to degrade in mechanical strength and recovery performance. Going beyond simple softening, Panasonic employed a unique resin design technology that makes optimal use of the characteristic three-dimensional cross-linked structure of thermosetting resin. By relaxing internal stresses arising from stretch, the newly developed insulating material returns to its original shape and withstands repeated use. This material helps realize electronic devices that remain wearable for an extended period of time.

3. Additional development of a stretchable transparent electrode material and conductive paste along with the insulating material

Devices implemented on clothing or worn on the body must be made of not only stretchable insulating materials, but also soft and stretchable conductive materials. Using a stretchable resin as a base material, Panasonic has also developed a transparent electrode material and conductive paste that remain conductive even after repeated cycles of stretch and restore. The transparent electrode material comprises a thin conductive layer of carbon nanotubes formed on the base material of stretchable resin. The conductive paste was produced by combining the stretchable resin, used as a binder, with silver filler. These materials help realize stretchable display devices and sensors.