Researchers from China claimed to achieve 20J/cc high energy density storage in ferroelectric MLCC ceramic capacitors by optimization of its structure. Their scientific paper “Global-optimized energy storage performance in multilayer ferroelectric ceramic capacitors” was published in Nature Communications journal.

Summary of the article:

- Energy Storage Optimization: The study focuses on optimizing the energy storage performance of multilayer ceramic capacitors (MLCCs) by constructing local polymorphic polarization configurations.

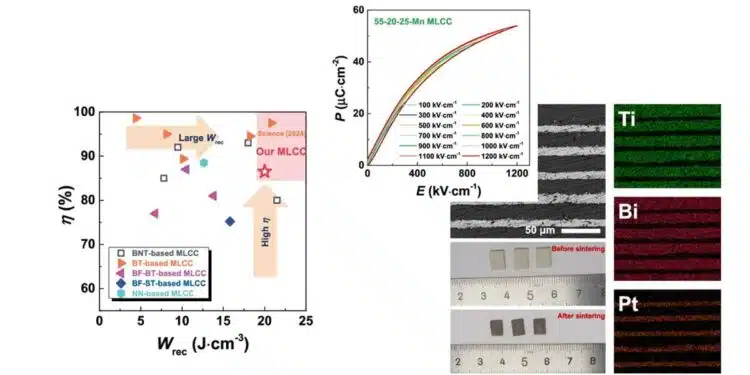

- High Energy Density and Efficiency: The optimized MLCCs achieved a large energy density of 20.0 J·cm⁻³ and a high efficiency of 86.5%.

- Temperature Stability: The capacitors demonstrated remarkable high-temperature stability, making them suitable for various applications.

- Manufacturing Process: The study highlights the use of tape-casting and screen-printing techniques to prepare MLCC prototype devices.

- Potential Applications: The findings suggest that the proposed strategy can be generally applicable in the design of high-performance energy storage multilayer ceramic capacitors.

Abstract

Multilayer ceramic capacitor as a vital core-component for various applications is always in the spotlight. Next-generation electrical and electronic systems elaborate further requirements of multilayer ceramic capacitors in terms of higher energy storage capabilities, better stabilities, environmental-friendly lead-free, etc., where these major obstacles may restrict each other.

An effective strategy for energy storage performance global optimization is put up here by constructing local polymorphic polarization configuration integrated with prototype device manufacturing. A large energy density of 20.0 J·cm−3 along with a high efficiency of 86.5%, and remarkable high-temperature stability, are achieved in lead-free multilayer ceramic capacitors.

The strategy provides a feasible routine from nano, micro to macro regions in manipulating local polarizations, domain-switching barriers and breakdown strength, illustrating its great potential to be generally applicable in the design of high-performance energy storage multilayer ceramic capacitors.

Technical Background

Multilayer ceramic capacitors (MLCCs), currently one of the most widely used and fastest-growing chip components globally, are extensively employed in diverse industries such as information technology, consumer electronics, communications, aerospace and industrial control on account of their large power density, stable mechanical properties and exceptional temperature stability. Compared with traditional single-chip ceramic capacitors, MLCCs typically exhibit a larger energy storage density. This is attributed to the fact that the tape-casting and lamination process used in preparing MLCCs lowers the porosity of the ceramic dielectric layer, and the breakdown strength (Eb) enhances exponentially with the significantly decreased dielectric layer thickness.

Theoretically, when the thickness of the dielectric layer and the number of stacked layers of MLCCs are defined, the attributes of the dielectric materials (such as chemical composition, grain size, or orientation structure, etc.) typically determine the crucial energy storage parameters of MLCCs. For example, Li et al. achieved a moderate Wrec of 9.5 J·cm−3 and a high η of 92% in the MLCCs with a composition of 0.55Bi0.5Na0.5TiO3-0.45Sr0.7Bi0.2TiO3. To further increase the energy storage density, they employed the template method to control the grain orientation and prepared the high-quality <111 > -textured MLCCs with the same chemical composition. The results indicate that the breakdown strength of the textured MLCCs could attain an astonishing 1030 kV·cm−1, and Wrec thereby achieved a significant breakthrough of 21.5 J·cm−3, along with an energy efficiency of approximately 80%. However, this optimization scheme is challenging to be mass-produced in the industry due to the strictness and complexity of the grain texture process. By contrast, although the BiFeO3-BaTiO3-based MLCCs doped with Nd(Zn0.5Zr0.5)O3, which can fulfill the requirements of mass production, can obtain a large Wrec of 10.5 J·cm−3 and a high η of 87% at room temperature, the η is merely approximately 70% at 150 °C. The high heating caused by this low energy efficiency will accelerate the failure of the MLCCs. Therefore, in addition to the pursuit of high energy storage parameters, considering that the ambient environment will gradually increase with heat dissipation during operation, attaining low loss at elevated temperatures is also a crucial technical indicator.

There is a consensus that the energy storage performance of capacitors is determined by the polarization–electric field (P–E) loop of dielectric materials, and the realization of high Wrec and η must simultaneously meet the large maximum polarization (Pmax), small remanent polarization (Pr) and high Eb. Over the past decade, a significant amount of effort has been exerted to optimize these parameters for enhancing the energy storage performance. For instance, strategies such as the template-induced texture approach, core-shell structure, multilayer structure, and improvements in the molding and sintering processes are employed to boost the Eb. Or the high-entropy approach, regulation in specific temperature regions, domain engineering, chemical composition design, and the construction of other polar structures can be utilized to suppress the polarization hysteresis and lower the energy loss. Through the judicious combination of the aforesaid strategies, the BT-based high-entropy MLCC, as disclosed in Science in 2024, attains the optimal comprehensive energy storage performance, specifically, a large Wrec of 20.8 J·cm−3 accompanied by a high η of 97.5%. However, it should be noted that the Wrec value of this MLCC at a high temperature of 100 °C is sharply decreased to approximately 10.6 J·cm−3, and the corresponding η is also reduced to around 85%, which hinders its broad applicability. Moreover, the chemical composition of this high-entropy MLCC is overly complex and delicate, and minor errors in industrial production can lead to significant differences in performance parameters.

An effective method to optimize the energy storage properties of dielectric materials is to regulate the structure of their domains or polar nano-regions (PNRs). A considerable number of studies have demonstrated that it is efficacious to construct R (rhombohedral) + O (orthorhombic) + T (tetragonal) + C (cubic), R + T + C, O + T and other polarization configurations in ferroelectrics through the utilization of specific dielectric temperature regions regulation, nano-scale polarization mismatch and reconstruction, and crossover region design. For instance, in the design of the energy storage thin film dielectrics, Pan et al. constructed an intriguing structure of R + T phase polymorphic nanodomains co-embedded within the C-phase matrix in the BiFeO3-BaTiO3-SrTiO3 thin film. The results indicated that the minimum polarization hysteresis was obtained while maintaining large Pmax, and eventually, a high Wrec of 112 J·cm−3 was accomplished. The η is approximately 80%. In addition, Chen et al. also realized local polymorphic (R + O + T + C) distortion and random oxygen octahedral tilt in K0.5Na0.5NbO3-based high-entropy ceramics.

The polarization anisotropy and energy barrier were significantly weakened, resulting in a smoother domain-switching path and a delayed polarization saturation, attaining a Wrec of 10.06 J·cm−3 along with a high η of ~90.8%. Combine this with the following fact: although binary systems (such as BNT-ST, BNT-NN, and NN-ST) constituted by Bi0.5Na0.5TiO3 (BNT, R phase), NaNbO3 (NN, O phase), and SrTiO3 (ST, C phase), which are regarded as the most promising lead-free energy storage systems, have been extensively investigated, the domain structure, polarization configuration and energy storage characteristics of BNT-NN-ST ternary system have not been deeply explored. Based on the above considerations, we propose that BNT, whose polarization characteristics are much higher than those of other lead-free ferroelectrics due to the hybridization between Bi 6 s and O 2p orbitals, be taken as the main component, combines with NN with a broad-band gap to construct an R + O + T + C coexistence polarization configuration. and then introduces ST to further break the long-range ferroelectric order to establish local polymorphic polarization configuration of ultra-small size. To improve the energy storage capacity of ceramic capacitors and promote their application in more environments and a wider range, ceramic powders with such local polymorphic polarization configuration were selected to prepare MLCC prototype devices by tape-casting process and screen-printing technique.

Conclusion

Through the experimental and theoretical analysis, we successfully established the composition-structure-performance correlation in the BNT-NN-ST system, our data set confirms that the construction of local polymorphic polarization configuration can greatly reduce the polarization hysteresis and improve the breakdown strength.

The excellent energy storage properties of the 55-20-25-Mn MLCCs, characterized by a large Wrec of 20.0 J·cm−3 and a high η of 86.5%, obtained in this work are derived from the guidance of mesoscale phase-field simulation and the fabrication of prototype devices, demonstrating the great application potential of ceramic dielectric capacitors.

The proposal of this strategy, which combines the design of local polymorphic polarization configurations and the fabrication of MLCC prototype devices, will benefit the optimal design of most energy storage capacitors and can trigger design considerations for other multifunctional materials.

For more details, you can read the full article here.: Li, D., Liu, Z., Zhao, W., Guo, Y., Wang, Z., Xu, D., Huang, H., Pang, L., Zhou, T., Liu, W., & Zhou, D. (2025). Global-optimized energy storage performance in multilayer ferroelectric ceramic capacitors. Nature Communications, 16(1), 1-9. https://doi.org/10.1038/s41467-024-55491-5