Silicon based capacitors are typically single MIM (metal-insulator-metal) or a multiple MIM structure electrostatic capacitors build by semiconductor technologies.

Silicon dielectrics are either silicon dioxide (MIS) or silicon nitride (MOS) insulating layers, however semiconductor manufacturing techniques such as atomic layer deposition (ALD) can be used to form other dielectric materials on top of silicon substrate. High density silicon based capacitors are using 3D nano-structured electrodes to achieve higher surface area and thus higher capacitance value.

Key Takeaways

- Silicon capacitors utilize silicon dioxide or silicon nitride dielectrics and offer high stability, reliability, and miniaturization suitable for harsh environments.

- They exhibit strengths like high temperature stability up to 250°C, low leakage current, and long lifetimes but have a limit on maximum capacitance.

- Advanced techniques like 3D nano-structured electrodes and atomic layer deposition (ALD) enhance performance and efficiency in silicon capacitors.

- Though they offer superior performance, silicon capacitors are more expensive than traditional options like MLCCs, limiting their use in certain applications.

- High-density silicon capacitors achieve low losses and improved volumetric efficiency, making them ideal for specialized fields like automotive, aerospace, and military applications.

Introduction

Silicon-based dielectrics such as silicon dioxide and silicon nitride are commonly used in high-density capacitors. Capacitors with silicon dielectrics are ideal for applications that demand high stability, reliability, and tolerance to high temperatures. The performance characteristics of these capacitors make them a suitable choice for use in harsh environment applications. The following are the key strengths and limitations of silicon-based dielectrics.

Strengths of silicon-based dielectrics

High stability at high temperature

The performance of most capacitors is significantly affected by exposure to high temperature. Silicon capacitors are available in different temperature ratings, usually up to 250oC. High temperature silicon capacitors are suitable for a broad range of harsh environment applications including aircraft engine controls, avionics systems, automotive systems, downhole oil exploration systems, military applications, and so on. In addition, silicon capacitors offer highly stable capacitance performance as a function of voltage and temperature. Although the maximum capacitance of silicon capacitors is limited, they do not suffer ageing of capacitance. Moreover, unlike X7R and X8R capacitors, the reliability and capacitance of silicon capacitors are not degraded under DC bias conditions.

High potential for miniaturisation

Silicon-based dielectrics are commonly used in the fabrication of high density electronic devices. High density silicon capacitors are usually fabricated in ultra-deep trenches, and they have very low leakage current and low loss factor. Passive integration connective substrate (PICS) is the most common technology for implementing high density capacitors. This process allows implementation of multi-chip modules (MCMs) and chip on board (COB), and it helps to realise smaller components with low power consumption. In addition, this process allows integration of many basic functions into a single product, thereby helping to cut manufacturing costs. By employing latest technologies, high volumetric efficiencies have been achieved. It is expected that the volumetric efficiency of silicon capacitors will continue to improve as the demand for high performance and miniaturised components continues to grow. So far, silicon capacitors with layers that are thinner than those of multilayer ceramic capacitor (MLCC) technology have been achieved.

Leakage current stability at high temperature

Leakage current is one of the capacitor parameters that can be affected when a capacitor is subjected to high temperatures. The dielectric material is the key factor that determines the leakage current of a capacitor. Over stressing the dielectric material can significantly increase the leakage current. The charging voltage and the thickness of the dielectric also have a slight effect on the leakage current of a capacitor. As compared to most high temperature capacitors in the market, silicon capacitors have impressive leakage current-temperature characteristics. In addition, silicon-based dielectrics offer impressive insulation resistance that makes them an unmatched choice for coupling, blocking, and timing circuits.

Low failure rate

Capacitors find a wide range of applications in electronic circuits. As such, they are one of the most common passive components in electronic systems. The reliability of a capacitor is a factor of its failure rate. As compared to other passive components, capacitors have a higher rate of failure. Some of the key factors that determine the failure rate of a capacitor include operating time and loading conditions. Comparative reliability tests have shown that high temperature silicon capacitors have better FIT (failure in time) rates as compared to high temperature X8R capacitors.

Limitations of silicon-based dielectrics

Limited maximum capacitance

Although silicon capacitors have impressive characteristics including high stability at high temperature, very low leakage current, high insulation resistance, and high capacitance density, there is a limit to the maximum capacitance that can be achieved. It is expected that the latest advancements in technology will help to overcome this technological limitation. In addition to improving the fabrication process, manufacturers are exploring alternative dielectrics as a solution to the major technical barriers associated with silicon-based dielectrics.

Charge leakage

SiO2 is commonly used in the fabrication of capacitors for microelectronics devices. These capacitors are constructed by oxidizing silicon and using the oxide as the dielectric material. Since capacitance is directly proportional to area of the dielectric material and inversely proportional to the thickness of the dielectric, manufacturers of electronic devices have been decreasing the area and thickness of the dielectric material to obtain miniaturized and high density devices. As the thickness of the SiO2 dielectric film is decreased, the charge leakage through the dielectric material increases. Beyond a certain limit, it becomes difficult for the capacitor to store charge due to the leakage problem. Although DRAM manufacturers are using deep trenches to overcome leakage problem, the dielectric thickness limitation is a major barrier to miniaturisation of microelectronic devices. Apart from improving the implementation process, manufacturers are also exploring alternative dielectrics to overcome this limitation.

Silicon Based Capacitor Structure and Features

Silicon based capacitors are typically single MIM (metal-insulator-metal) or a multiple MIM structure capacitors build by semiconductor technologies. Silicon dielectrics are either silicon dioxide (MIS) or silicon nitride (MOS) insulating layers, however semiconductor manufacturing techniques such as atomic layer deposition (ALD) can be used to form other dielectric materials on top of silicon substrate. High density silicon based capacitors are using 3D nano-structured electrodes to achieve higher surface area and thus higher capacitance value.

Structure of semiconductors and MOS capacitor – its band gap diagrams, work functions and electron affinity concepts are beyond this article scope. We will focus on description of silicon based capacitors on the market and its key features.

Silicon MIS and MOS Capacitors

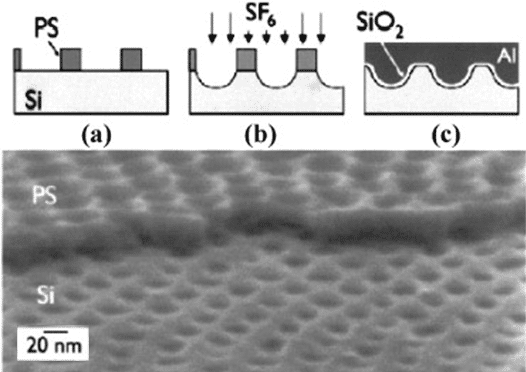

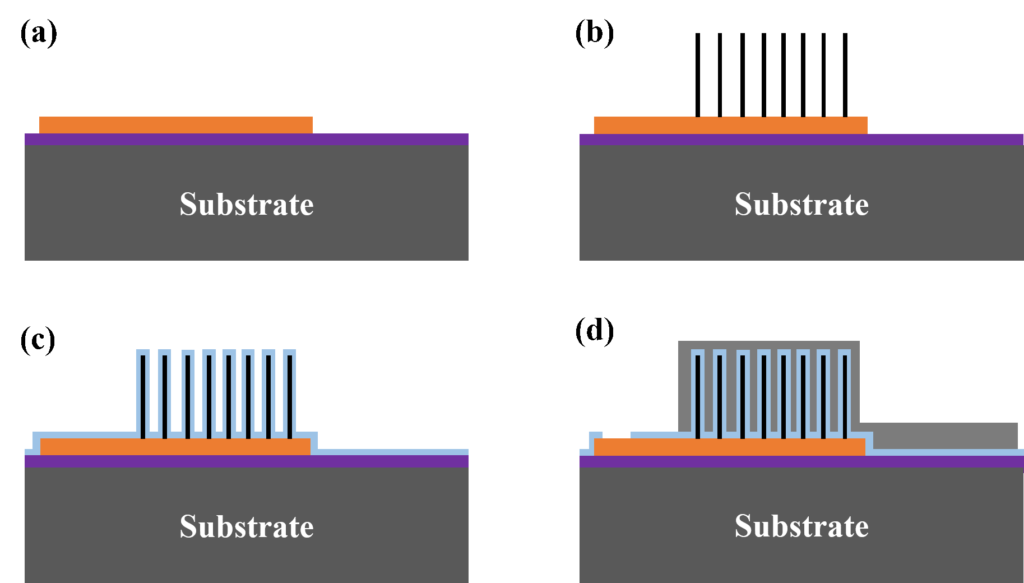

Silicon-based dielectrics are used within semiconductor manufacturing processes of high density electronic devices by semiconductor manufacturing processes. Silicon based dielectrics for capacitor technologies are usually based on silicon dioxide (MIS) or silicon nitride (MOS) insulating layers. Figure 1. below describes a conventional MOS technology to make silicon capacitors.

Conventional Technology MOS Capacitor Process

(a) Polymer template formation on silicon surface

(b) RIE pattern transfer of PS template into silicon, followed by the removal of the PS matrix.

(c) SiO2 growth followed by top Al gate electrode deposition

Silicon capacitors can be manufactured and used as

- fully MIS/MOS compatible back-end technology as part of passive integration platform

- hetero-integrated as Multiple-Chip-Module or flip-chip with other technologies (CMOS, MEMS, etc.) in a system in chip (SiP) or on chip (SoP)

- discrete chip SMD capacitors

Single Layer RF Silicon Capacitors

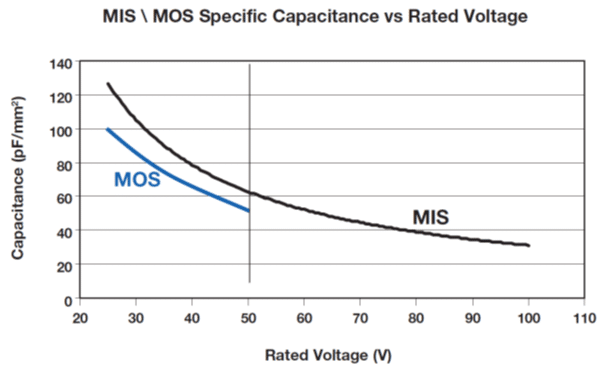

Silicon-based dielectrics are used to make low loss, high Q capacitors that feature very high temperature stability, high breakdown voltage and low leakage parameters. The main limitation is relatively low permittivity. Comparison of MIS and MOS dielectrics – see Table 1. and Figure 2. below.

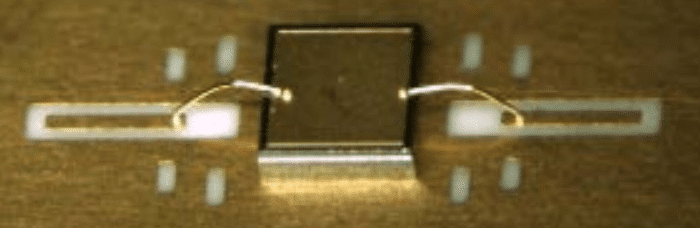

Gold or aluminum wire thermosonic and ultrasonic bonding are the most common way to assemble the single layer silicon capacitors (SLCs) in RF applications. Termination styles may differ and it can be optimized for epoxy or solder die attach mounting techniques. Examples – see Figure 3.

RF Thin Film Silicon Capacitors

Silicon thin film capacitors (Figure 4.) are typically based on a single layer silicon oxide/nitride dielectric deposited on a substrate and packed in a chip MLCC like design. It offers unique ability of very low capacitance values (0.05pF) and very tight capacitance tolerances (±0.01pF). Thin film technology guarantees minimal batch to batch variability of parameters at high frequency and thus it is an ideal component for RF and microwave filters.

The term “thin film capacitors” however relates to a wider range of thin film technologies using also other dielectrics such as ceramic or organic films deposited on various substrates types such as alumina, quartz, silicon or silicon wafer.

Thus, distinction between “thin film”(deposited on silicon substrate) and “silicon” capacitors is something of a marketing concession, though significant differences exist within & among the two depending on the intended application.

Devices targeting RF tuning & matching applications tend to be low-capacitance, single-layer devices optimized for parameter stability and consistency, and are commonly found in standard JEDEC package sizes.

In contrast, devices intended for power supply decoupling, broadband DC blocking, and similar applications allow larger tolerances in favor of achieving higher specific capacitance, and are more likely to be found in packaging adapted to advanced assembly methods such as wire bonding or embedding within a PCB. Regardless of intended application however, devices in the thin film and silicon capacitor families are premium-performance products and are priced accordingly, currently fetching something on the order of 5 to 5000 times the price of ceramic devices with similar capacitance and voltage ratings.

3D Silicon High Density Capacitors

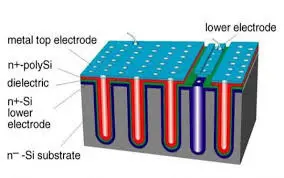

High density silicon capacitors are usually fabricated in ultra-deep trenches to increase surface area of electrodes. They have very low leakage current and low loss factor. Passive integration connective substrate (PICS) is the most common technology for implementing high density capacitors. This process allows implementation of multi-chip modules (MCMs) and chip on board (COB), and it helps to realize smaller components with low power consumption. In addition, this process allows integration of many basic functions into a single product, thereby helping to cut manufacturing costs. See Figure 5. on right – 3D PICS capacitor structure.

By employing latest 3D technologies, high volumetric efficiencies up to 1300nF/mm2 have been achieved. Silicon capacitors can be manufactured in layers below 100um that are 4xthinner than those of multilayer ceramic capacitor (MLCC) technology. Manufactured of silicon capacitors are claiming 10x better reliability in comparison to MLCC capacitors and in combination with ultra high temperature stability up to 250C, the high density silicon capacitor technology enable number of high demanding applications in automotive, industrial/oil drilling or aerospace/defense industry. It is expected that the volumetric efficiency of silicon capacitors will continue to improve as the demand for high performance and miniaturised components continues to grow.

Silicon capacitors – key features

- High Q, low losses

- Thin layers sub 100um possible

- High temperature operation (up to 250C)

- High reliability lifetime expectancy (10x better than MLCC, as example: full rated 10V continuous operation at 250°C for 50years)

- Low leakage < 30nA/mF; Higher leakage current at high temperatures (but still 1000x lower compare to the other technologies)

- No/low radiation sensitivity

- No derating required

- No catastrophic failure mode

- Low weight

- Stable performance with tight capacitance tolerances

- No piezo effect

- Non-magnetic

- Relatively low permittivity

Silicon Wafer Based Integrated Capacitors

Integrated capacitors and passives have a lot going for them. They take up less space on a PCB, they simplify design and they can, with the right processes shrink circuit tolerances thanks to closer component matching. The downside is that, as with semiconductors, volume is everything.

Although a common reason for keeping passive components off-chip is their size relative to that of the transistors on-die – is not worth wasting precious silicon area on devices that cost more to assemble than their materials are worth – many off-the-shelf parts rely on passives to tune filters and control loops for specific applications.

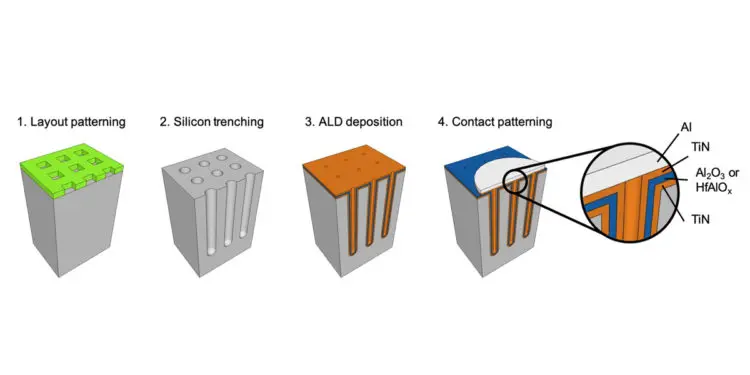

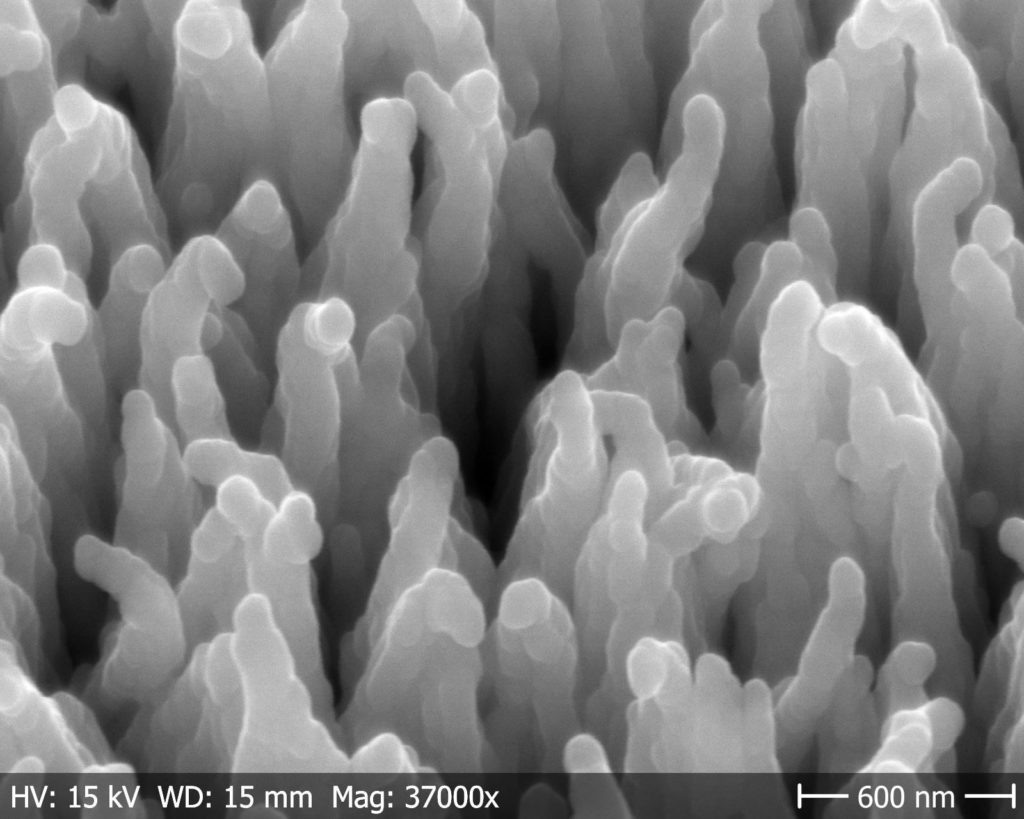

Utilization of semiconductor fabrication processes, however, has resulted in number of new approaches towards high density micro-capacitors. Finish company Picosun used its atomic layer deposition ALD equipment, to deposit film stacks of conductive TiN and insulating dielectric Al2O3 and HfAlO3 layers into high aspect ratio trenches etched into silicon that increased capacitance density up to 1 µF/mm2. ALD deposition and 3D microcapacitor manufacturing process is shown in Figure 6. below.

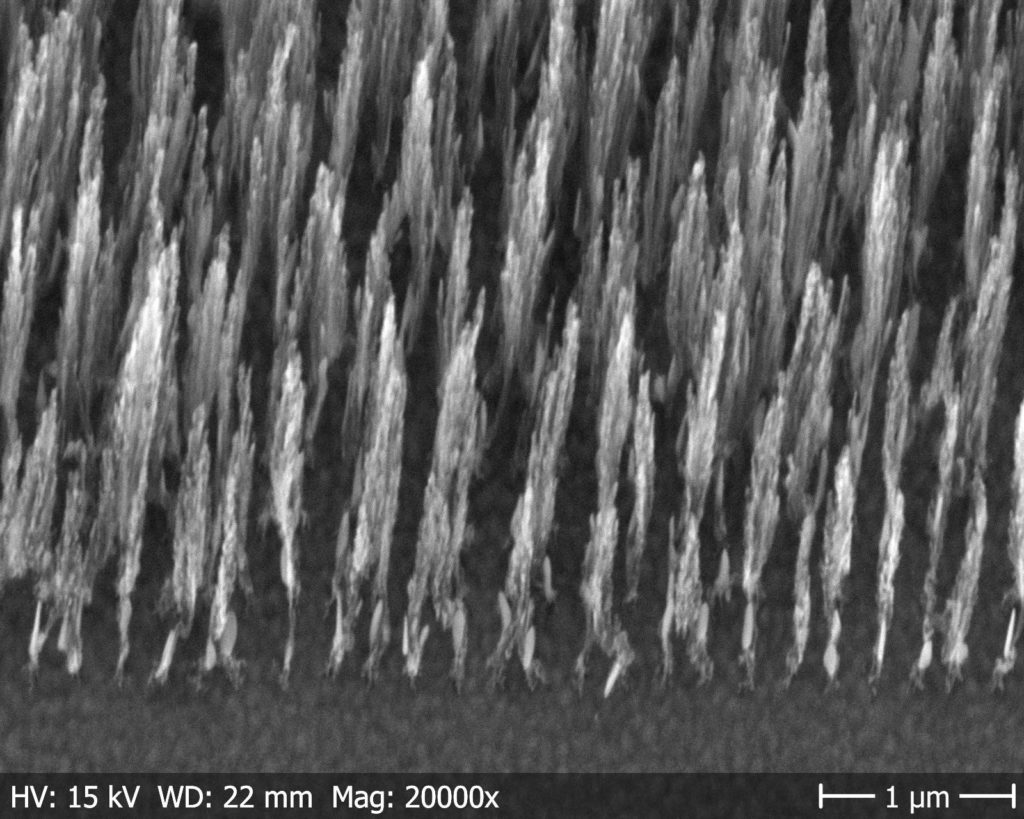

Swedish company Smoltek received Outstanding and Best Paper Award at EPCI PCNS conference for their carbon nano-fiber metal-insulator-metal (CNF-MIM) wafer based semiconductor technology achieving capacitance density to +650nF/mm2 at the end of 2019. They used ALD technique to deposit Al2O3/HfO2 layers onto carbon nano-fiber 3D structure.

The fiber length is only 2 – 3 µm and the total height profile of the complete device is ca 4 µm. This makes the capacitors readily available for integration onto a CMOS chip or in 3D stacking. Figure 7-9. below shows the CNFs after the dielectric coating via ALD, the image showing a coating of Al2O3/HfO2/Al2O3 (5/3/5 nm). The dielectric layer is uniformly covering the individual CNFs.

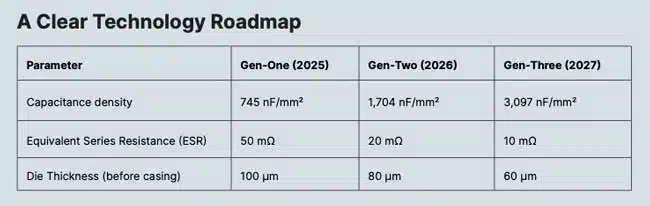

In update of Smoltek technology, the company released in 2025 its commercialization strategy document that includes the CNF-MIM capacitors technology roadmap as shown in Fig. 10.

Frequently Asked Questions about Silicon Capacitors

Silicon-based capacitors use silicon dioxide or silicon nitride dielectrics, fabricated with semiconductor technology. They can be manufactured as metal-insulator-metal (MIM) structures and are used for high stability, reliability, and miniaturization applications.

Applications demanding high temperature stability and reliability—such as avionics, automotive systems, oil exploration, and military electronics—benefit most from silicon capacitors. Their stable capacitance at high temperatures makes them ideal for harsh environments.

– High stability at high temperatures (up to 250°C)

– Excellent leakage current stability

– High potential for miniaturization

– Low failure rates and long lifetimes

– No ageing under DC bias conditions

– Limited maximum achievable capacitance

– Increased charge leakage as the dielectric thickness decreases

– Relatively low permittivity compared to ceramic types

– Higher cost compared to MLCCs

Manufacturers use 3D nano-structured electrodes, ultra-deep trench fabrication, and atomic layer deposition (ALD) to increase surface area and volumetric efficiency, enabling thin layers and higher capacitance densities. Technologies from companies like Picosun and Smoltek use ALD for record capacitance density integration.

How to Select and Use Silicon Capacitors for High-Density, High-Reliability Applications

- Identify Application Requirements

Determine if your project demands high temperature stability, low leakage, miniaturization, or integration into semiconductor packages and advanced multi-chip modules.

- Choose the Appropriate Silicon Capacitor Structure

– For RF applications: Select single-layer or thin-film silicon capacitors with low capacitance, high Q, and stability.

– For high-density needs: Opt for 3D integrated capacitors with ultra-deep trench structures and higher volumetric efficiency. - Evaluate Performance Parameters

Review the temperature range (up to 250°C), leakage current specifications, capacitance stability, tolerances, and lifespan. Compare these to alternative technologies like MLCC.

- Consider Fabrication and Mounting Options

Decide between discrete SMD types, embedded capacitors within PCBs, or integration with CMOS/MEMS as system-in-chip or system-on-package. Check compatibility with wire bonding and surface mount techniques.

- Assess Cost vs. Performance

Silicon capacitors are premium components with higher costs than MLCCs, but offer substantial reliability, miniaturization, and performance benefits in demanding environments.