Pablo Blázquez, Power Εlectronics Εngineer of Frenetic in this blog explains main transformers and inductors winding losses key contributors: Skin and Proximity losses.

Transformers and Inductors get warm when they’re in use? Well, part of the reason lies in what we call Winding Losses.

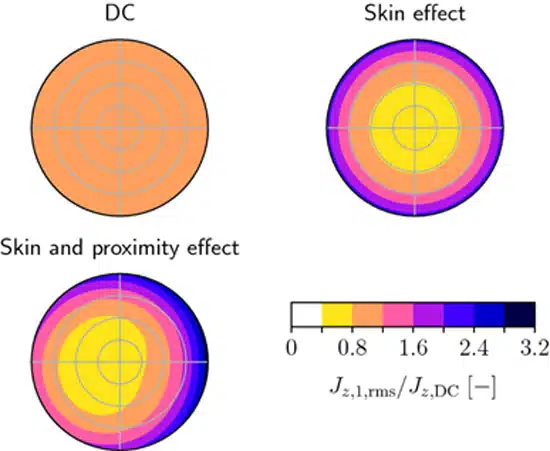

My focus for today is to explain what I´ve learned about the specific effects that lead to these losses and temperature rise, with a particular focus on two key players: skin and proximity losses – see Figure 1.

By understanding how they impact the efficiency and performance of our magnetic components, we will know how to combat these effects.

Skin Losses

Skin losses, also known as skin effect losses, are an important aspect of winding losses in Transformers and Inductors. When the alternating current flows through the wire, it tends to concentrate more on the outer surface due to the skin effect. This results in an underutilization of the inner part of the wire, that leads to energy losses. The current prefers the outer layers of the wire, leaving the inner layers unused.

Minimizing skin losses is crucial for the optimization of these devices’ efficiency. We can reduce wasteful energy dissipation by ensuring a more even distribution of current across the wire.

When it comes to combating this effect, different winding designs come into play. One popular solution is the use of Litz wire, which is composed of multiple individually insulated strands woven together. This configuration helps to distribute the current more evenly across the wire, therefore reducing the skin effect and minimizing energy losses. It’s like giving each strand of spaghetti a fair share of the delicious sauce!

Proximity Losses

Proximity losses are another significant component of winding losses in Transformers and Inductors that deserves our attention. When multiple windings are in close proximity to each other, their magnetic fields interact, and this results in energy losses. It’s like neighboring windings interfering with each other’s magnetic moves, causing inefficiencies. To minimize these losses, proper insulation between the windings is crucial. By implementing insulation techniques, we can reduce the magnetic coupling between the windings, mitigating proximity losses.

Think of it as creating a barrier between dancers at a party, preventing their magnetic interactions from causing excessive energy dissipation. Understanding and addressing proximity losses is key to enhancing the efficiency and performance of our winding designs.

Wire Types Winding Losses Impact

Different types of wire configurations have varying impacts on both skin and proximity losses in Transformers and Inductors.

Litz Wire

As said before, it is composed of individually insulated strands woven together, which significantly reduces skin losses. Distributing the current more evenly across the wire mitigates the concentration of current on the outer surface, thereby minimizing energy dissipation. Additionally, proper insulation between the strands helps to reduce proximity losses by limiting magnetic coupling between adjacent windings.

Rectangular Wires

They offer a favorable shape for reducing skin losses. The wider surface area allows for better current distribution, minimizing the concentration of current on the outer surface and reducing energy dissipation. Proximity losses can also be mitigated with careful positioning and insulation.

Round Wires

Although common and easy to work with, round wires tend to have higher skin losses compared to other shapes. The circular cross-section results in a larger surface area, leading to more concentrated current flow on the outer surface and increased energy losses. Proximity losses can also be influenced by round wires, as their close positioning may result in stronger magnetic interactions.

Foil Conductors

Composed of flat strips, they excel at reducing skin losses due to their larger surface area. The flattened shape provides improved current distribution and decreases energy dissipation. Proximity losses can be controlled by proper insulation and spacing between adjacent foil conductors.

By considering the characteristics of each wire type, such as the distribution of current and magnetic interactions, you can make mindful choices to optimize winding designs and minimize both skin and proximity losses. Understanding how these different wire configurations impact losses is vital for achieving enhanced efficiency in transformers and inductors.

Conclusion

In conclusion, understanding and addressing winding losses, in particular skin and proximity losses, is essential for optimizing the efficiency and performance of Transformers and Inductors.

- Skin losses occur due to the concentration of current on the outer surface of the wire, leading to underutilization of the inner layers and energy dissipation.

- Minimizing skin losses can be achieved through techniques like using Litz wire, which evenly distributes the current across multiple insulated strands.

- Proximity losses arise when magnetic fields from adjacent windings interact, causing energy losses.

- Proper insulation between windings helps reduce magnetic coupling and mitigate proximity losses.

- The choice of wire configuration also plays a significant role in minimizing losses. Litz wire, rectangular wires, and foil conductors offer advantages in reducing skin losses, while proper positioning and insulation can mitigate proximity losses. Understanding the characteristics of different wire types allows for informed choices in optimizing winding designs.

By addressing these losses, we can enhance the efficiency and performance of magnetic components, ensuring their optimal operation.