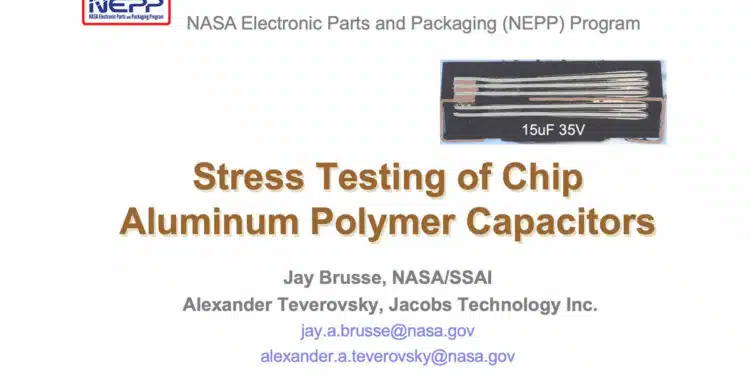

This paper Stress Testing of Chip Aluminum Polymer Capacitors was authored by Alexander Teverovsky Jacobs Technology Inc., NASA/GSFC and presented by Jay Brusse, NASA/SSAI during the 5th Space Passive Component Days (SPCD), an International Symposium held from October 15th to 18th, 2024, at ESA/ESTEC in Noordwijk, the Netherlands. Published under permission from ESA SPCD organizers.

Introduction:

The study “Stress Testing of Chip Aluminum Polymer Capacitors” by Alexander Teverovsky explores the reliability and performance of Aluminum Polymer Capacitors (APCs) as potential alternatives to traditional chip tantalum capacitors.

Given their advantageous properties such as lower Equivalent Series Resistance (ESR), reduced weight, and compact size, APCs present promising applications, particularly in space environments.

However, there is limited comprehensive data on their reliability under various environmental stress conditions.

Key Points:

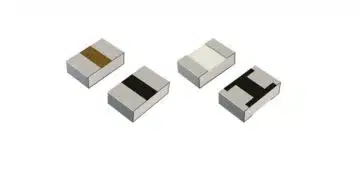

- Scope of Study: Analysis of seven types of commercial APCs from four vendors, rated from 6.3 to 35 V.

- Testing Conditions: High-temperature storage (100–150 °C), high humidity (85 °C), and Highly Accelerated Life Tests (HALT) at voltages 1.2–1.9 times the rated voltage.

- Parameters Measured: Breakdown voltages, anomalous charging currents (ACC), capacitance, Dissipation Factor (DF), ESR, and leakage currents.

- Comparison: Reliability compared with Polymer Tantalum Capacitors (PTCs).

Extended Summary:

The introduction contextualizes APCs’ development, tracing their evolution from cylinder aluminum cases to chip designs that facilitate surface-mount assembly, boosting their appeal for modern electronic applications. The study emphasizes the need to understand their reliability, especially considering their growing usage in industries like automotive and aerospace.

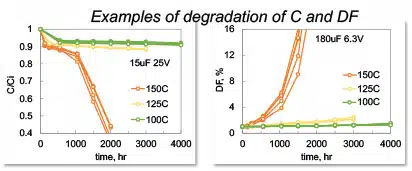

APCs were subjected to rigorous experiments, including high-temperature storage tests at varying conditions (100, 125, and 150 °C) and humidity exposure tests.

The capacitors demonstrated different degradation rates based on temperature, with significant ESR increases observed at extreme temperatures. Parametric failures were defined by specific thresholds in capacitance loss, DF increase, and ESR rise. The degradation mechanisms were linked to thermo-oxidative processes and moisture impacts on the dielectric materials.

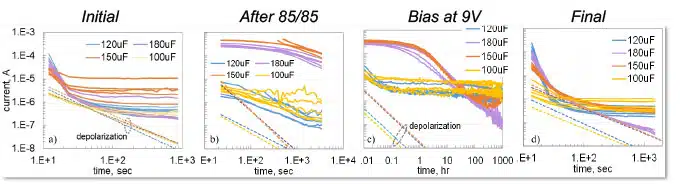

Humidity tests revealed that while APCs are sensitive to high moisture environments, some types managed to maintain stability under moderate humidity conditions. Interestingly, leakage currents increased significantly after exposure to high humidity but tended to decrease under bias, indicating self-recovery mechanisms similar to those in PTCs.

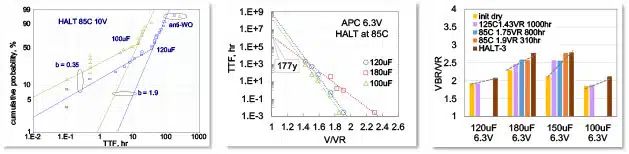

HALT experiments highlighted the capacitors’ behaviors under excessive stress. The study observed infant mortality failures, wear-out mechanisms, and “anti-wear-out” phenomena, where certain capacitors exhibited improved breakdown voltages after prolonged stress. The results suggested that APCs could achieve extended lifetimes under controlled operating conditions, with projected life spans exceeding several decades when appropriately derated.

Conclusion:

The comprehensive analysis indicates that APCs, with proper handling, screening, and derating, can be viable for demanding applications, including spaceflight.

Their performance under stress conditions is comparable to, and in some cases exceeds, that of PTCs. Nevertheless, variability among different manufacturers underscores the necessity for rigorous qualification protocols.

The findings support the broader adoption of APCs while highlighting areas for future research, particularly concerning long-term reliability in extreme environments.

Read the full paper: