TAIYO YUDEN CO., LTD. has commercialized four items, including the high temperature multilayer metal power inductor MCOIL™, which complies with the “AEC-Q200” reliability qualification test standard for passive automotive components.

Through advancements made in our proprietary metal materials and multilayer construction methods, we have achieved an upper operating temperature limit of 165°C for a multilayer metal power inductor, a world’s first.

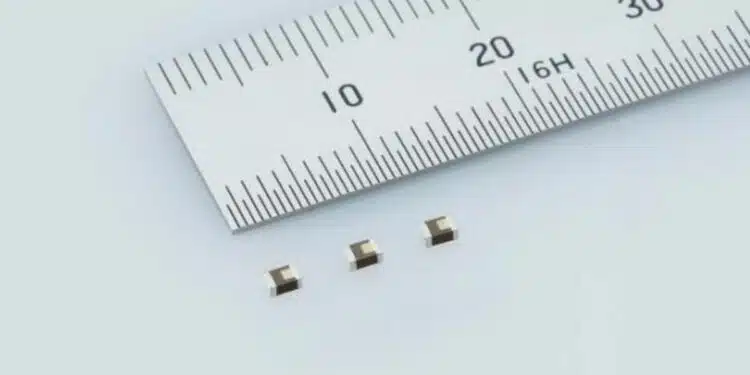

These products LACNF2012KKTR24MAB” (2.0 x 1.25 x 1.0 mm, maximum height value shown) are used as choke inductor coils in DC-DC converters used in automotive engine ECUs, control systems such as BMS, safety systems such as ABS, body-related systems such as ADAS, and information systems such as instrument clusters.

By extending the upper operating temperature limit range of our conventional product “LCCNF2012KKTR24MAD” (operating temperature range: -55°C to +150°C) to 165°C, these new products are able to contribute to the miniaturization and performance enhancement of power supply circuits by enabling high-density mounting in high-temperature environments such as in automobiles.

Mass production of these products began at our subsidiary, WAKAYAMA TAIYO YUDEN CO., LTD. (Inami-cho, Hidaka-gun, Wakayama Prefecture, Japan), in April 2024. Samples are available for 50 yen per unit.

The advancements that we have seen in recent years in electronic controls in production vehicles, as typified by ADAS units, has led to a greater number of power supply circuits on vehicles, which in turn has led to growth in the demand for power inductors that are used in these circuits. Furthermore, performance also continues to improve through functional integration, such as in integrated cockpits that combine instrument clusters and infotainment devices.

While the throughput of IC chips continues to grow as these devices become increasingly multifunctional and high-performance, there is also a growing need to make on-board electronic components smaller and thinner in order to arrange devices in highly dense configurations and integrate them into single modules. Components mounted at high densities become more susceptible to the effects of heat, as their reduced volumes makes it more difficult for the heat generated by the components to dissipate.

Furthermore, since ECUs are increasingly being installed in engine compartments—a high temperature environment—on-board electronic components must be able to withstand high temperatures. To address these challenges, TAIYO YUDEN further improved the reliability of the MCOIL™ LCCN series of multilayer metal power inductors, which had the advantage of being smaller and thinner, and launched the AEC-Q200 certified LACN series which provides an extended operating temperature range of – 55°C to +165°C.

TAIYO YUDEN focuses on the development of products that meet market needs, and will continue to expand its power inductor product lineup.

Application

Choke coils in DC-DC converters used in automotive engine ECUs, control systems such as BMS, safety systems such as ABS, body-related systems such as ADAS, and information systems such as instrument clusters.