Researchers from Regional Centre of Advanced Technologies and Materials CATRIN Olomouc and VSB Ostrava, Czech republic published a scientific paper describing replacement of NMP solvent used in conventional supercapacitor electrode manufacturing with green alternatives.

Introduction

The article investigates how to transition supercapacitor electrode manufacturing away from the toxic solvent N‑methyl‑2‑pyrrolidone (NMP) toward greener solvents while maintaining or improving electrochemical performance and mechanical robustness. Supercapacitors require high power density, fast charge–discharge, and long cycle life, but large‑scale deployment increasingly faces regulatory pressure to eliminate hazardous processing chemicals such as NMP.

To address this, the authors evaluate two greener organic solvents, dihydrolevoglucosenone (Cyrene) and N‑butyl‑2‑pyrrolidone (Tamisolve), in combination with a nitrogen‑doped graphene active material (SC‑GN3) and two binders: fluorinated PVDF and non‑fluorinated PVP. The study focuses on industrially relevant high mass loading (>6 mg cm), adhesion and flexibility of the coating on carbon‑coated aluminum current collectors, and long‑term cycling in a symmetric two‑electrode supercapacitor configuration.

Key points

- NMP, a standard solvent for carbon‑based electrode slurries, is toxic and strongly regulated, motivating replacement by greener solvents in supercapacitor manufacturing.

- Cyrene and Tamisolve are introduced as low‑toxicity solvents that can dissolve PVDF or PVP sufficiently to prepare stable, high‑solid‑content slurries of nitrogen‑doped graphene (SC‑GN3).

- SC‑GN3 is a nitrogen‑doped multilayer graphene with high nitrogen content (~16.2 at.%) and defect density, providing high surface charge, good wettability, and stable dispersions in NMP, Cyrene, and Tamisolve.

- Electrodes with 87 wt% SC‑GN3, 3 wt% binder, and 10 wt% conductive carbon (Timcal) were fabricated on carbon‑coated Al foil with mass loading of 6.2–7.1 mg cm using a scalable slurry‑casting and calendaring process.

- PVDF–Cyrene electrodes achieved a gravimetric capacitance of 152 F g at 1 A g, energy density of 66.6 Wh kg, power density of 1.85 kW kg, ESR as low as 6.9–7.1 Ω, and 91 % capacitance retention after 100 000 cycles at 10 A g.

- PVP–Cyrene electrodes provided a more environmentally benign binder–solvent system with capacitance of 133 F g, energy density of 64.2 Wh kg, power density of 1.80 kW kg, and 78 % retention after 100 000 cycles.

- Cyclic voltammetry and impedance analysis show predominantly electric double‑layer behavior, minimal Faradaic contribution, low ESR, and good ion transport despite the high mass loading.

- Mechanical bending tests and tape‑based grid adhesion tests demonstrate strong adhesion and cohesion for PVDF–Cyrene and PVDF–Tamisolve electrodes, and excellent flexibility (with fewer cracks) for PVP–Cyrene films.

- The study establishes the first high‑mass‑loading supercapacitor electrodes using fully green solvent–binder systems and proposes practical mechanical tests suitable for industrial electrode development.

Extended summary

The work starts from the problem that conventional supercapacitor electrode fabrication relies heavily on NMP, which offers excellent solvency for PVDF and carbon materials but is classified as a reproductive and developmental toxin and subject to REACH and TSCA restrictions. The challenge is to identify greener solvents that deliver similar dispersion quality, film formation, adhesion, and electrochemical performance, while also enabling scalable processing of high‑mass‑loading electrodes needed for practical devices. Additionally, there is a push to replace fluorinated binders such as PVDF with non‑fluorinated alternatives like PVP to further reduce environmental impact.

The active material used is a nitrogen‑doped graphene derivative, SC‑GN3, synthesized at 100 g scale from graphite fluoride via azidation in DMF followed by extensive solvent washing and purification. XPS analysis confirms a nitrogen content of up to 16.2 at.% with contributions from pyridinic and pyrrolic nitrogen, while SEM and TEM reveal multilayer 2D sheet morphology. FTIR and Raman spectra show aromatic and heteroatom‑related bands, and a D/G intensity ratio of 1.09, indicating a high density of defects beneficial for charge storage and wettability. These structural features, combined with the polarity of Cyrene, Tamisolve, and NMP, yield stable dispersions without significant sedimentation over several hours, unlike in acetone or acetonitrile where SC‑GN3 rapidly sediments.

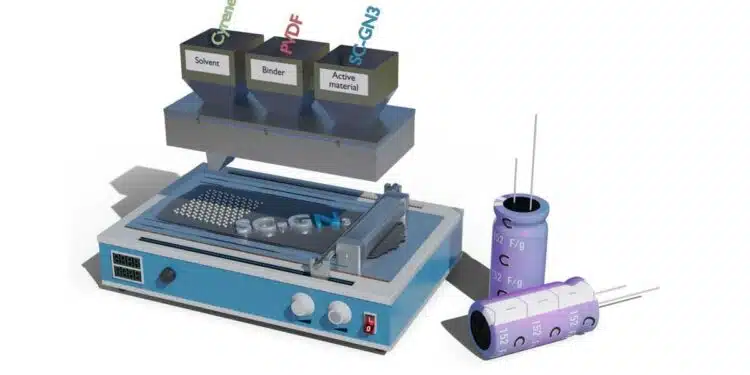

The electrodes are formulated with 87 wt% SC‑GN3, 3 wt% PVDF or PVP, and 10 wt% Timcal Super C45. The fabrication route follows industrially relevant slurry processing: the binder is first dissolved in NMP, Cyrene, or Tamisolve under controlled stirring and sonication conditions optimized per solvent, then mixed with the conductive additive and SC‑GN3 using vortex mixing and a planetary mixer to achieve a paste‑like slurry. The slurry is coated on carbon‑coated aluminum foil using a doctor blade, dried at 120 °C in vacuum, calendared, and punched into 18 mm disks, yielding total electrode mass loadings of 15.8–18 mg per electrode (6.2–7.1 mg cm). Symmetric two‑electrode supercapacitor test cells are assembled in El‑Cell hardware with glass microfiber separators and a mixed electrolyte consisting of an ionic‑liquid‑based component [EMIM][BF4] + TTE and an organic salt component [TEA][BF4] in propylene carbonate, giving ionic conductivity of about 2.01 mS cm and viscosity of 11.0 mPa s.

Electrochemical characterization is performed using galvanostatic charge–discharge (GCD), cyclic voltammetry (CV), and electrochemical impedance spectroscopy (EIS) in a 3.7 V window. The specific capacitance Cs of the active material (including binder and conductive carbon) is obtained from GCD discharge bywhere I is the discharge current, Δt the discharge time, ΔV the potential window, and m the total active mass on both electrodes; the factor 4 converts the full‑cell two‑electrode configuration to a single‑electrode specific capacitance. The energy density in Wh kg is calculated aswhere is again the operating voltage window, the factor normalizes to the full‑cell mass, and 3.6 converts joules per gram to Wh kg. The power density is thenwith the discharge time corresponding to the energy . The equivalent series resistance is evaluated from the GCD IR drop usingwith the total active mass of both electrodes, and the factor 1000 correcting for gram–kilogram units.

With these definitions, the authors compare six binder–solvent combinations: PVDF–NMP, PVDF–Cyrene, PVDF–Tamisolve, PVP–NMP, PVP–Cyrene, and PVP–Tamisolve (the latter failing mechanically). PVDF–NMP, representing the conventional system, delivers 131 F g at 1 A g, ESR of 9.8 Ω, and exhibits typical triangular GCD curves with small IR drops and nearly rectangular CVs indicative of EDLC behavior. Replacing NMP with Cyrene enhances performance: PVDF–Cyrene achieves 152 F g, ESR around 6.9–7.1 Ω, and excellent long‑term cycling with 91 % capacitance retention after 100 000 cycles at 10 A g, corresponding to 66.6 Wh kg and 1.85 kW kg at 1 A g. PVDF–Tamisolve yields intermediate performance, with 140 F g, ESR 10.2 Ω, and 82 % retention after 100 000 cycles, still outperforming many literature supercapacitors at similar mass loading.

Transitioning to PVP as a non‑fluorinated binder, the authors observe slightly reduced performance but improved sustainability. PVP–NMP reaches 117 F g and ESR of 7.9 Ω, while PVP–Cyrene reaches 133 F g, energy density of 64.2 Wh kg, power density of 1.80 kW kg, and 78 % capacitance retention after 100 000 cycles. CV curves at high scan rates show distorted rectangles due to the high mass loading but no pronounced redox peaks, confirming that charge storage is dominated by electric double‑layer mechanisms rather than pseudocapacitance from nitrogen functionalities, which may be suppressed by ion‑transport limitations in thick electrodes. EIS Nyquist plots show small high‑frequency semicircles and steep low‑frequency lines, indicating low charge‑transfer resistance, minimal Faradaic reactions, and good ionic accessibility of the porous structure despite the thickness. Leakage current, self‑discharge, and voltage‑hold tests indicate that device‑level configuration and electrolyte dominate these behaviors more than the specific binder–solvent combination.

Beyond electrochemical metrics, the study rigorously examines mechanical properties critical for industrial roll‑to‑roll processing. Bending tests around a stainless‑steel rod (180° bend) show that PVDF–Cyrene and PVDF–Tamisolve electrodes maintain strong adhesion to the carbon‑coated Al foil but develop more pronounced surface cracking than PVP‑based films. PVP–Cyrene films exhibit superior cohesion and flexibility with minimal cracking under the same bending conditions, making them attractive for flexible or wearable applications where strain tolerance is prioritized. Repeated bending (100 cycles) of PVDF–Cyrene causes only a moderate increase in in‑plane resistance from about 125–230 Ω cm to 145–359 Ω cm, confirming stable mechanical integrity.

Adhesion is quantified using a modified ISO‑2409/ASTM D3359 cross‑cut grid test combined with sequential application of adhesive tapes with defined adhesion forces from 0.8 to 10.6 N cm. PVDF–NMP shows adequate adhesion but poor cohesion; material is partially removed even with the weakest tape, leaving many residues on the tape. Introducing Cyrene or Tamisolve significantly improves adhesion and cohesion: PVDF–Cyrene and PVDF–Tamisolve electrodes remain largely intact even after peeling with the strongest tape, despite their high mass loading. PVP–Cyrene films, while mechanically flexible, adhere more weakly to the carbon‑coated Al, and PVP–Tamisolve films delaminate entirely during drying regardless of temperature, preventing electrochemical testing. The authors highlight that such simple bending and tape tests provide a practical, low‑equipment framework to assess mechanical suitability of electrode formulations for industrial manufacturing.

Overall, the results show that Cyrene and Tamisolve can replace NMP in SC‑GN3‑based supercapacitor electrodes without sacrificing, and in some cases improving, electrochemical performance, while also enabling high mass loading, strong adhesion, and long cycling life. The trade‑off is that the most sustainable formulation (PVP–Cyrene) exhibits somewhat lower capacitance and cycling stability than PVDF–Cyrene, likely due to PVP’s hydrophilicity, moisture adsorption, and possible interactions with the electrolyte at 3.7 V.

Conclusion

The article demonstrates that green solvents Cyrene and Tamisolve can effectively replace NMP in high‑mass‑loading supercapacitor electrodes based on nitrogen‑doped graphene, while maintaining or improving electrochemical and mechanical performance relative to the conventional PVDF–NMP system. PVDF–Cyrene in particular delivers high capacitance, low ESR, excellent cycling stability, and strong adhesion at industrially relevant loadings, making it a strong candidate for immediate deployment in cylindrical and other wound‑cell formats.

At the same time, the work introduces PVP–Cyrene as a fully green solvent–binder combination that offers competitive capacitance and energy density with superior flexibility, albeit with reduced cycling stability and weaker adhesion to carbon‑coated aluminum. Limitations include the need to better understand binder–electrolyte interactions at high voltage, to mitigate PVP‑related degradation, and to optimize processing for PVP–Tamisolve systems that currently delaminate. Future work may focus on tailoring binder chemistry, surface treatments, and electrolyte formulations to further improve the stability and adhesion of non‑fluorinated binder systems, as well as extending the green‑processing framework to other active materials and device architectures.

References

- Dědek, I.; Kupka, V.; Šedajová, V.; Jakubec, P.; Navrátil, M.; Otyepka, M. “Toward transitioning to green and sustainable supercapacitors,” Chemical Engineering Journal, In Press, 2025. Available at: https://www.sciencedirect.com/science/article/pii/S1385894725130696