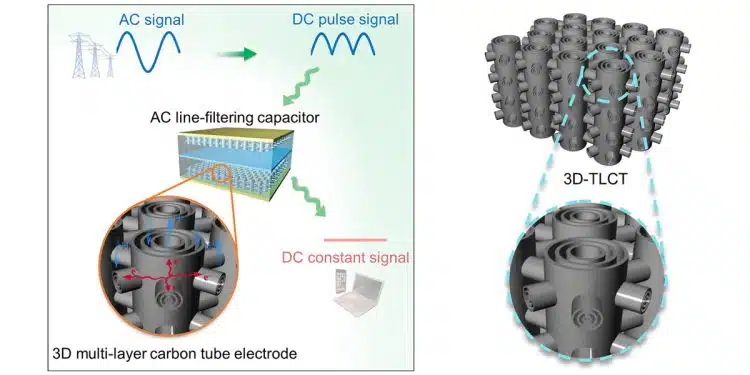

Researchers from China and USA demonstrated novel 3D multi-layer carbon tube electrodes for AC line-filtering supercapacitors.

We report three-dimensional multi-layer carbon tube electrodes for miniaturized filter capacitors, and the structure of the electrodes can be precisely controlled.

These capacitors exhibit desirable capacitance for carbon nanotube-based EDLCs and excellent filtering characteristics for line-filtering applications and could be integrated into miniaturized devices.

Alternating current line-filtering capacitors are critical for digital circuits and electronics. Aluminum electrolytic capacitors (AECs) are the most used filter capacitors, but their bulky size has hindered their application in miniaturization. Electric double-layer supercapacitors (EDLCs), whose capacitance is much higher than AECs, are expected to be miniaturized filter capacitors. However, achieving EDLCs with high-frequency and high-capacitance performances is challenging. Designing high-oriented and high-density carbon-based electrodes would minimize the performance trade-off between frequency response and capacitance.

Abstract

Electric double-layer capacitors (EDLCs) have the potential to replace aluminum electrolytic capacitors for alternating current line-filtering, aligning with the trend of device miniaturization. However, it is challenging for EDLCs to simultaneously achieve rapid ion migration, electrical response, and high areal and volumetric capacitances.

Here, we demonstrate that three-dimensional, structurally integrated multi-layer carbon tube (3D-MLCT) frameworks are used as electrodes for high-performance filtering EDLCs. By simply increasing the number of tube layers, a high specific areal capacitance of 3.08 mF cm−2 at 120 Hz is achieved with a phase angle of −80.1°, exhibiting excellent capacitance and fast frequency response. The outstanding performance of the 3D-MLCT is attributed to the high density, high orientation, and high integrality of carbon tube arrays that facilitate and accelerate ion distribution onto the electrode surface. The findings of this work provide a solution for developing next-generation miniaturized filter capacitors with high capacitance and fast frequency response.

Introduction

Converting alternating current (AC) into direct current (DC) is essential for powering electronics. In the process, filter capacitors play a crucial role in smoothing the ripples in the rectified DC signal. Aluminum electrolytic capacitors (AECs) dominate this field but occupy the most significant volume in circuits. Electric double-layer capacitors (EDLCs), storing energy physically through reversible ion adsorption at the electrode-electrolyte interface, have been anticipated for fast frequency response applications.

EDLCs are considered promising alternative devices for AC line-filtering to meet the demands of miniaturized electronic devices owing to their several-orders-of-magnitude-higher specific capacitance than commercial AECs. However, conventional EDLCs behave more like resistors than capacitors and possess poor frequency response performance at an indicator frequency of 120 Hz because of their tortuous and complicated pore structure as well as the high resistances of the electrodes.

The first filtering EDLC was reported by Miller et al., with discrete vertically oriented graphene (VOG) nanosheets grown on nickel substrates as electrodes, demonstrating an outstanding AC line-filtering performance. Subsequently, various carbon-nanomaterial-based electrodes with high orientation, thin thickness, and macro-porous structures have been explored for filtering EDLCs. However, the specific areal (CA) and volumetric capacitances (CV) are still at a low level—the bottleneck of miniaturized filter devices.

Recently, we have demonstrated three-dimensional carbon tube (3D-CT) grid-based electrodes with integrated structures for line-filtering applications. The 3D-CT grids, employed as the electrodes of EDLCs, showed exceptional line-filtering capabilities owing to their 3D-ordered design, functional CT units, chemical bond connections, high conductivity, stable open-pore structures, and interconnected lateral and vertical carbon tubes that facilitate smooth ion distribution channels.

The preliminary results reported of filling CTs with smaller-diameter carbon nanotubes (CNTs) (3D-CNT@CT) have blazed a trail in enhancing CA effectively. However, due to the relatively sparse distribution and unoriented alignment of smaller CNTs inside the CTs, the increase in CA is limited, and the rapid migration of ions inside CTs is hindered. To further improve CA to meet the expectations of miniaturized filter capacitors, the CTs could be uniformly filled with concentric tubes that replicate their original morphology to provide rich ion-accessible surface areas while maintaining the high orientation of the interconnected structure.

This kind of “tube nested inside tube” functional unit, similar to Russian matryoshka dolls, could be combined in an orderly manner to obtain a unique 3D-CT-based framework with a controllable number of CT layers and inter-layer spacing. Therefore, filling multi-layered CTs (vertical and lateral) within the initially integrated 3D-CTs would be an attractive and rational design to significantly increase the CA without degrading the frequency response performance.

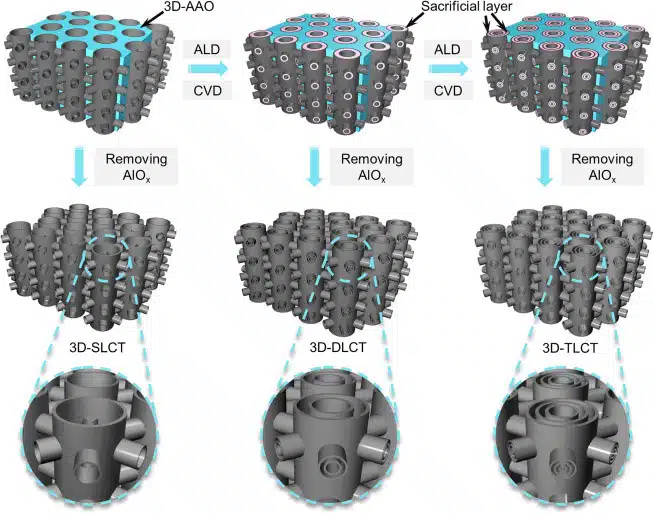

Herein, we report structurally integrated 3D multi-layer CT (denoted as 3D-MLCT) frameworks that are used as electrodes for high-performance line-filtering EDLCs, showing high CA and fast frequency response capability. The 3D-MLCT framework was fabricated via a combinational process with a 3D porous anodic aluminum oxide (3D-AAO) as a template, including chemical vapor deposition (CVD) of CTs in the 3D pores of 3D-AAO, atomic layer deposition (ALD) of an alumina layer as the sacrificial material, CVD of inner CTs, and then chemically etching the alumina layer and the 3D-AAO template.

3D single-layer, double-layer, and triple-layer CT frameworks (denoted as 3D-SLCT, 3D-DLCT, and 3D-TLCT) have been constructed by controlling the number of layers. The 3D-TLCT-based EDLC exhibits a desirable CA value of about 3.08 mF cm−2 at 120 Hz with a phase angle below −80°, over 70% higher than the value of 3D-CNT@CT (1.81 mF cm−2). To verify practicability, ten EDLCs based on the 3D-MLCTs assembled in series to filter a rectified 120-Hz pulse DC signal and a pulse voltage signal generated from a triboelectric nanogenerator (TENG) have shown gratifying line-filtering performances.

The excellent performances of the 3D-MLCT-based EDLCs are attributed to the high density, orientation, and integrality of the 3D-ordered structure composed of functional MLCT units that facilitate and accelerate ion distribution onto the electrode surface. The findings of this work provide a unique solution for developing next-generation miniaturized line-filter capacitors with high capacitance and fast frequency response.

Results and Discussion

The fabricating process of 3D-MLCT is schematically illustrated in Figure 1. A 3D-AAO template with interconnected vertical and lateral channels was synthesized by anodizing impure aluminum foil in phosphoric acid electrolyte at 0°C under a voltage of 195 V. The template was placed into a horizontal tube furnace and heated to 1,000°C at 10°C/min under an Ar atmosphere. The first CT layer was deposited on the pore walls of the 3D-AAO template with a flow of acetylene gas under vacuum conditions for 50 min.

Subsequently, an AlOx layer was deposited via an ALD process at 250°C on the inner wall of the first CT layer using trimethyl aluminum (TMA) and ozone (O3) as the precursors. The second CT layer was deposited on the AlOx surface via a second-time CVD process. Similarly, repeating the ALD and subsequent CVD processes can prepare a third CT layer. Finally, the 3D-MLCT was obtained after removing the AlOx layer(s) and 3D-AAO template in hydrofluoric acid solution, and the spacing of adjacent CT layers can be precisely controlled by the thickness of the AlOx layers. Furthermore, the size of the 3D-CT films can be adjusted by varying the area of the 3D-AAO as needed, and we prepared a 3D-CT film with an area of approximately 24 cm2.

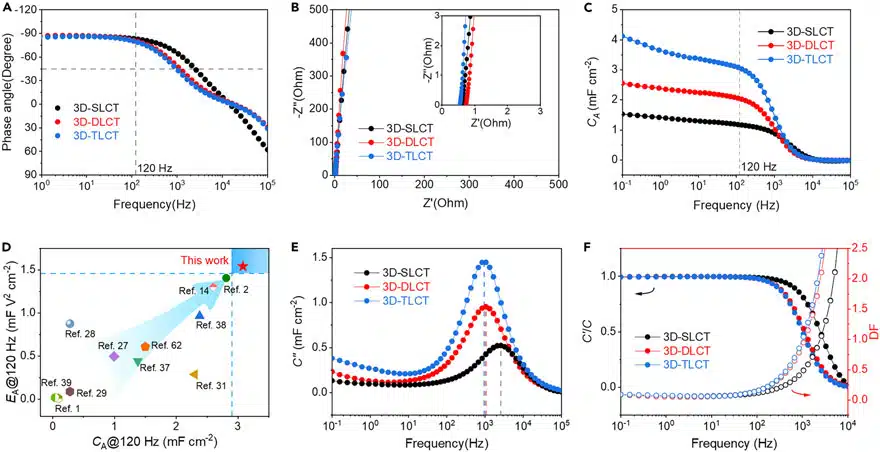

Symmetrical cells with a two-electrode configuration were constructed using the 3D-CT films as electrodes, platinum sheets as the current collectors, and a 1M H2SO4 aqueous solution as the electrolyte. The 3D-DLCT-24-based EDLC with an electrode thickness of 12 μm can achieve both a low phase angle (<−80°) and a high CA (>2 mF cm−2), demonstrating an outstanding application potential for AC line-filtering.

All the 3D-CT-based EDLCs show a small equivalent series resistance (ESR), which can be attributed to the excellent electrical conductivity of the 3D-MLCT and the good contact with the current collectors. These results indicate that the double-layer and triple-layer CT frameworks allow fast ion distribution and electron conduction dynamics, provided by the ordered smooth pore channels and high conductivity of the 3D-CT frameworks.

(A–C) (A) Bode plots, (B) Nyquist plots, and (C) specific areal capacitance (CA) of the 3D-SLCT-, 3D-DLCT-, and 3D-TLCT-based EDLCs. The inset shows the expanded view at high frequencies.

(D) Comparison of CA and areal specific energy density (EA) of the 3D-TLCT-based EDLC at 120 Hz, with other reported aqueous electrochemical capacitors with a symmetric sandwich-type device configuration used in the AC filter circuits.

(E) Plots of the imaginary part of the specific capacitance (C″) versus frequency based on the series-RC circuit model.

(F) The variation of C′/C and dissipation factor versus frequency.

The frequency-dependent capacitive behavior is further analyzed using the complex capacitance concept. The real part of the capacitance (C′) represents the actual accessible energy at the corresponding frequency, while the imaginary part (C″) is caused by energy dissipation due to resistive diffusion and leakage currents. At 120 Hz, the CA (i.e., the areal C′) of the 3D-SLCT-, 3D-DLCT-, and 3D-TLCT-based EDLCs can achieve 1.18, 2.05, and 3.08 mF cm−2, respectively. The areal specific energy density (EA) at 120 Hz of 3D-TLCT-based EDLC is calculated to be about 1.54 mF V2 cm−2, greater than most aqueous filtering capacitors with sandwich-type configurations reported to date.

Experimental

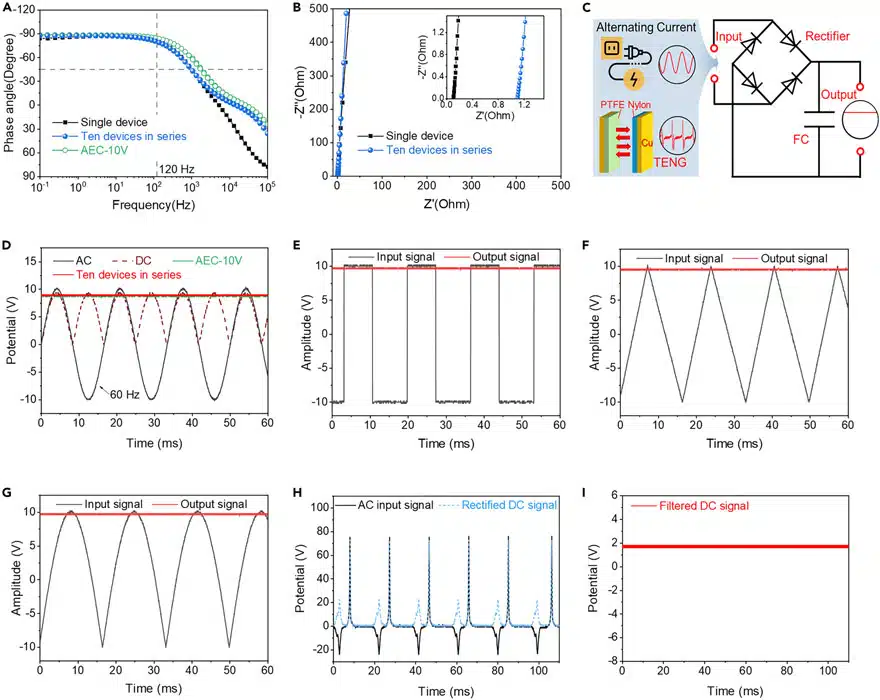

To create a more realistic comparison, ten identical 3D-DLCT-24-based capacitors (with an electrode area of ∼1 cm2 and thickness of 10 μm) were connected in series to expand the operating voltage to 10 V compared with the standard 10-V AECs.

The four-electrode test was adopted to evaluate the EIS of the EDLCs in series. The phase angles at 120 Hz of ten devices in series achieve −80.7°, comparable to that of the single device (−81.5°) and slightly inferior to the AEC (−84.8°)

The capacitance of the 10 devices in series (143 μF) is higher than that of commercial AEC (100 μF). Also, the same τ0 value of 0.96 ms is observed, confirming that good frequency response performance can be maintained by connecting EDLCs in series. The C′/C values are close to 1 at 120 Hz, indicating low energy loss and high practical energy storage efficiency, consistent with the results of the relatively low DF value. It should be noted that the DF of the capacitor bank is still relatively high compared with commercial AECs, but this can be improved by reducing the thickness of the 3D-DLCT electrodes. These measurements suggest that the high-frequency response and rate capability performance of 3D-DLCT-24-based EDLCs are maintained well when working in the serial connection.

A filter circuit employing ten 3D-DLCT-24-based EDLCs in series was built to verify their AC line-filtering performances. The input 60-Hz AC signal is converted into a 120-Hz sinusoidal signal without negative voltage by the full-bridge rectifier. The rectified signal is further smoothed into a constant DC signal required by the electrical appliances.

The AC input signals (±10 V of the peak voltage) with a loading resistance (RL) of 100 kΩ can be filtered into the DC output with a trivial ripple voltage, which is comparable to that of AEC (10 V/100 μF, Nippon, Japan), and demonstrates the potential applicability of the 3D-DLCT-24-based EDLCs used as filter capacitors at relatively high voltages. Under different high loadings, the capacitor banks in series exhibit comparable output voltages and small variance coefficients compared with AECs. The high specific capacitance, low ESR, and small τRC of the 3D-DLCT-based EDLCs guarantee promising prospects in fabricating practical high-frequency devices with prosperous filtering functions.

(A) Bode plots.

(B) Nyquist plots.

(C) Schematic of the rectifier and filter circuit powered by AC voltage and TENG pulse voltage.

(D) AC line-filtering results of ten EDLCs in series and commercial AEC (10 V/100 μF, Nippon, Japan) with RL of 100 kΩ.

(E–G) The filtering performances of the 3D-DLCT-24-based EDLCs for 60 Hz AC input signals with (E) square, (F) triangular, and (G) arbitrary waveforms.

(H and I) Electrical signals powered by TENG at (H) initial AC state, rectified state, and (I) filtered DC state.

The volumetric capacitance at rated voltage (CV vol) of 3D-DLCT-based EDLCs was compared with commercial AECs. The calculated CV vol for the 3D-DLCT-based EDLCs in the aqueous electrolyte is 0.15/V 2, where V is the voltage rating. 3D-DLCT-based EDLCs can be connected in series to achieve a higher operating voltage. The volumetric capacitance is higher at operating voltages of <16 V than commercial AECs. The operating voltage of a single EDLC can be increased when an organic electrolyte is used, and the EDLC also shows a high capacitive and filtering performance. CV vol will increase to 0.70/V 2, and the 3D-DLCT-based EDLCs have volumetric advantages over commercial AECs at voltages of <100 V.

Summary

In summary, structurally integrated, freestanding 3D-MLCT frameworks with multi-layered tube-in-tube structures were fabricated by a combinatorial process of alternating CVD and ALD using a 3D-AAO template and subsequent selective etching.

EDLCs based on the 3D-TLCTs exhibit a large areal specific capacitance of 3.08 mF cm−2 and a phase angle of −80.1° at 120 Hz, demonstrating excellent frequency response performances. High voltage filter capacitors can be achieved by connecting the EDLCs in series.

The results provide a solution for developing next-generation miniaturized filter capacitors with high capacitance and fast frequency response.

Read the full article:

Gan Chen, Fangming Han, Dou Lin, Shiping Zhang, Qijun Pan, Cheng Shao, Zhaoming Wang, Xiaoguang Zhu, Guowen Meng, Bingqing Wei,

Three-dimensional multi-layer carbon tube electrodes for AC line-filtering capacitors, Joule, 2024, ISSN 2542-4351,

https://doi.org/10.1016/j.joule.2024.01.026.