Connector Designs

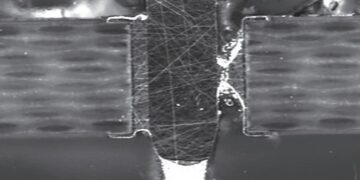

Soldering Quality

As per the IPC-A-610D, a compliant solder joint must fill at least 75% of the free volume between the pin...

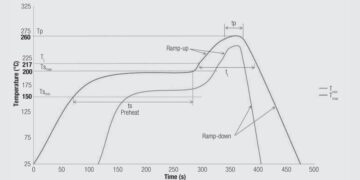

Read moreDetailsSolder Reflow Practice

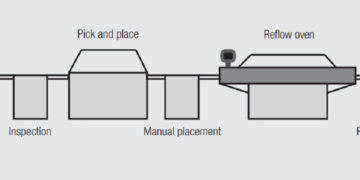

As noted previously, the THR reflow practice is basically identical to the SMT reflow practice. As such, it can be...

Read moreDetailsComponent Insertion

Whenever possible, it is desirable to use automatic pick and place technologies to insert the connectors into the PCB PTH....

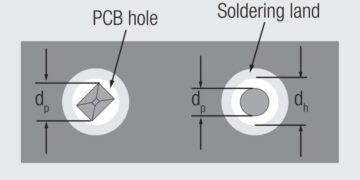

Read moreDetailsPin Geometry

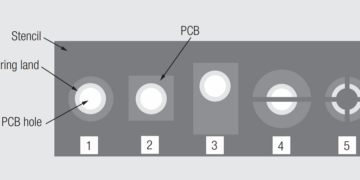

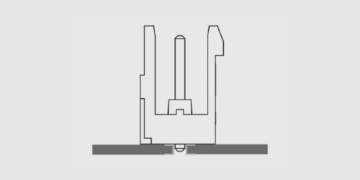

Basically, pins can be round or any rectangular shape, as shown in Figure 2.95. The pin geometry plays an important...

Read moreDetailsSolder Paste Application

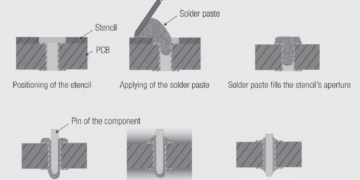

The solder paste is applied to the PCB and a subsequent squeegee pass is used to push the paste into...

Read moreDetailsSolder Paste Volume

The solder paste volume on the PCB surface will be determined by the thickness and area of the stencil opening....

Read moreDetailsScreen Printing

The screen printing process is particularly important because it determines the amount of solder paste that will be applied to...

Read moreDetailsThe THR Manufacturing Process

The basic requirement of a THR manufacturing process is to ensure compatibility with the existing SMT manufacturing process, typical stages...

Read moreDetailsComponent Lead Terminations

In a lead-free world, the most common finish is tin because of its very good wettability properties. However, tin can...

Read moreDetailsContact Considerations

Design and material change are also necessary for contacts, particularly the termination end of contacts. THR compatibility places additional requirements...

Read moreDetails