This paper was presented by Julien Logette, Axon Cable France during the 5th Space Passive Component Days (SPCD), an International Symposium held from October 15th to 18th, 2024, at ESA/ESTEC in Noordwijk, the Netherlands. Published under permission from ESA SPCD organizers.

Axon Cable is developing “connectorless” flat cable link solutions for the space market, featuring Zero Insertion Force (ZIF) connectors for PCB-mounted connections. The connectors, designed for both power and signal transmission, aim to enhance reliability by reducing connection points and are being optimized for space-grade applications. The project, part of an ongoing ARTES activity, seeks to achieve TRL 6 for these connectors, addressing the need for quick and easy integration in the growing space market.

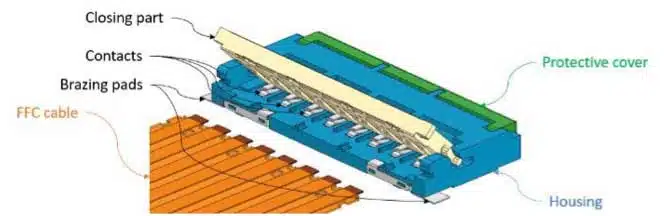

A new connector design for flexible flat cables (FFCs) is presented, featuring a Zero Insertion Force (ZIF) interface for easy cable insertion and removal. The connector is designed to accommodate various cable cross-sections and includes features for EMI protection, double insulation, and mechanical fixation. Preliminary results show promising pull test and electrical performance, meeting the requirements for space applications.

Design phase nearing completion, Critical Design Review scheduled for Q4 2024. Axon will produce prototypes and conduct tests to validate automotive and industrial technologies for space use.

Key Points

- FFC Advantages: Lightweight, flexible, superior heat dissipation, and higher current transmission compared to traditional round wires.

- FFC Applications: Ideal for complex situations, particularly in the growing space sector for smaller satellites and mega-constellations.

- Axon Cable’s Solution: Developing “connectorless” flat cable link solutions with fast-lock mechanisms for enhanced reliability and mass reduction in space applications.

- During this study, the reliability of the locking of the ZIF connector, the quality of the electrical contacts as well as the double insulation rules, which were taken into account and adapted to the flat structure, are optimized to achieve a ZIF connection suitable for use in space. The aim is to achieve TRL 6 for the development of ZIF connectors for PCBs capable of accommodating flat cables supporting DC or low-frequency signals or a DC power supply (up to 10 A per track).

Survey

During a preliminary survey, Axon’ identified several FFC connectors in the market, allowing direct connection between FFC and units. These identified connectors are for industrial activities and none are available for space market.

The existing suppliers identified are either Asian or American. No European solution is available on the market. Thus there is a double interest of developing an European and a space compatible solution.

Flat Cables and Connector Design

Flat cable design

The idea of this study was to develop a concept of connector that could be extended to various types of flat cables. Axon did the choice to select two flat cables already used on ongoing space projects, one for a power transmission application and the second one for signals transmission.

| Axon’ P/N | Section | Designation |

|---|---|---|

| P584261 | Power 0.735mm² (#AWG18) | FFC8x3.5×0.21 PI insulation + acrylic adhesive & SPC conductors |

| P584262 | Signal (#AWG26) | FFC20x1.0x0.12 PI insulation+ acrylic adhesive & SPC conductors |

Silver plated copper conductors (2 µm silver thickness) and 25 μm Polyimide tape insulation are used as a baseline of flat Flexible cable for space application. 76 μm Acrylic adhesive is used to fix the elements (insulation + flat conductors) as it has an excellent adhesion to copper and a good compatibility to space environment (low off gassing, good radiation resistance).

- Cable Design Standard: Double insulation based on ECSS-Q-ST-70-12C standard.

- Connector Design Goal: Easy installation and removal of flat cable without tools, zero insertion force.

- Contact Design Consideration: Material, shape, and thickness ensure electrical contact and limit forces.

- Connector Function: Positions, insulates, secures, and applies pressure to FFC cables and contacts.

- Connector Design: Accommodates 8 power supply tracks (AWG 18) and 20 tracks (AWG 26) with a locking mechanism.

- Materials and Features: LCP polymer housing, gold-plated Beryllium copper contacts and pads, optional EMI shielding.

- Connector Insulation: Insulation barriers prevent direct access between conductors.

- Soldered Joint Protection: Dedicated closing part protects and isolates connector terminations.

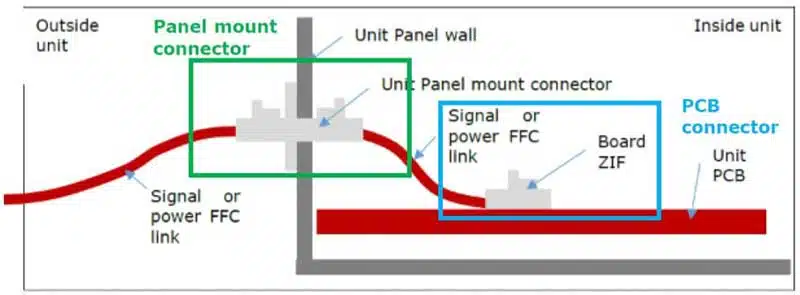

- Equipment Connector Design: Shielded ZIF interface bonded to the chassis outside the equipment and an unshielded ZIF interface inside the equipment.

Electrical results

Preliminary measurements on the prototypes were conducted despite the use of body parts and contacts not made from final materials and slightly optimized shapes.

Contact resistance shows values <20 mΩ for Signal connector and <10 mΩ for Power connector. Concerning electrical insulation and Dielectric Withstanding Voltage (DWV), measurements results are:

For Signal connector

- >30 GΩ with 500 VDC*

- >2000 VRMS with threshold current of 0.5 mA

For Power

- >30GΩ with 500VDC*

- >3000 VRMS with threshold current of 0.5 mA

*maximum measurement range of the equipment.

ECSS-Q-ST-12-C ask the following values: Insulation resistance >10E10 Ω (10 GΩ) and DWV >1000 VRMS/mm for track to track.

Conclusion

This article presents axon’s work on an ESA TDE to propose flexible electrical connections for satellites using flat cables. The focus is on connecting flat cables directly to PCBs or equipment for power and weak signals. Design optimizations were made based on feedback from tests and trials. The design is robust and reliable, suitable for the space sector.

The design phase is nearing completion, with the Critical Design Review scheduled for Q4 2024. Axon will produce evaluation prototypes and conduct tests to prove that automotive and industrial technologies can be adapted for space use.

Read the full article: