This article published by Samsung Electro-Mechanics discusses electric vehicle technology using high voltage applications and high voltage automotive MLCC ceramic capacitors.

The global car market is going through a massive transition to electric vehicles. So far, internal combustion engine (ICE) vehicles have improved powertrains to cope with emission regulations.

Emission regulations, convenience technologies and self-driving have driven electrification increases with automobiles.

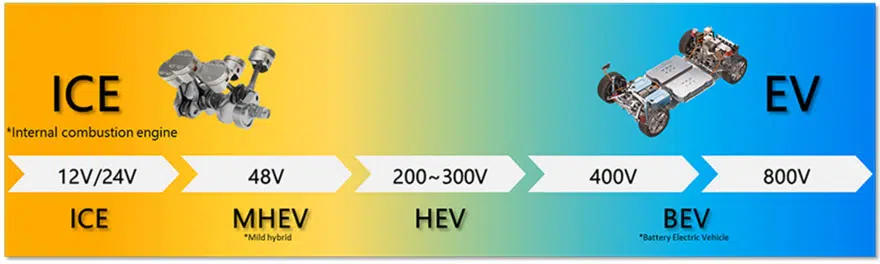

As the number of electronic units increased, the amount of power consumption for a vehicle increased. Battery voltages have changed to deal with increased power consumption requirements, and they are associated with efficient power systems.

Vehicle Electrification and Battery Voltages

The battery voltage increase of the car is related to the trend of electrification. In order to understand the electrification trend, we must first look back on how the voltage of a car battery has changed. Before the mid-1950s, a vehicles operating voltage was 6V. Since then, the engine displacements increased and required a large electric starter motor. The 12V system became standardized in the need of more electronic devices. Historically, early cars only needed a small battery to crank engine and turn on the radio.

However, as the number of in vehicle electronic devices has increased over time, so has the need for more power. To resolve this problem, discussions took place to increase the voltage from 12V to a higher voltage system capable of dealing with the additional power demand. In the 1990s, the 42V system was proposed, and in 2011, German carmakers made 48V the standard. Since then, hybrid cars and electric vehicles have begun to use higher voltages. Power (Watt) is voltage (V)*current (A). When increasing power, it is more efficient to raise the voltage rather than the current. When current is increased, thicker cables are required and connector pins must also be changed. Both have an impact on the hardware cost. So, battery voltages increased instead of current.

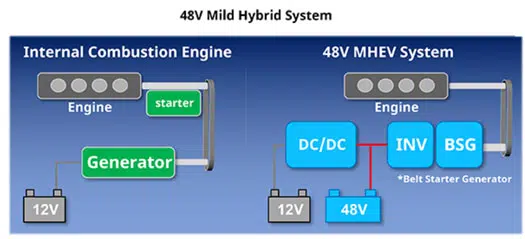

Battery voltage increase, 48V Mild Hybrid System

The main reason why the 48V system emerged in the 2010s was due to emission regulation.

Automakers producing internal combustion engines had to achieve their emission goals and increase fuel efficiency by improving powertrains. Mild Hybrid (MHEV) is said to be a simple inexpensive hybrid system. The reason why car manufacturers preferred MHEV is because it was easy to manufacture. The MHEV system can be manufactured by adding a 48V system to the existing internal combustion engine powertrain , emission reduction can be achieved at a lower cost than full-hybrid. But the question remains; why was 48V selected in particular? The reason is that,in many countries, 60V is regarded as a low voltage and not dangerous to the human body. In addition to the above, telephone lines have used 48V power systems for the last 100 years, which further proves the safety aspect of 48V systems in vehicles.

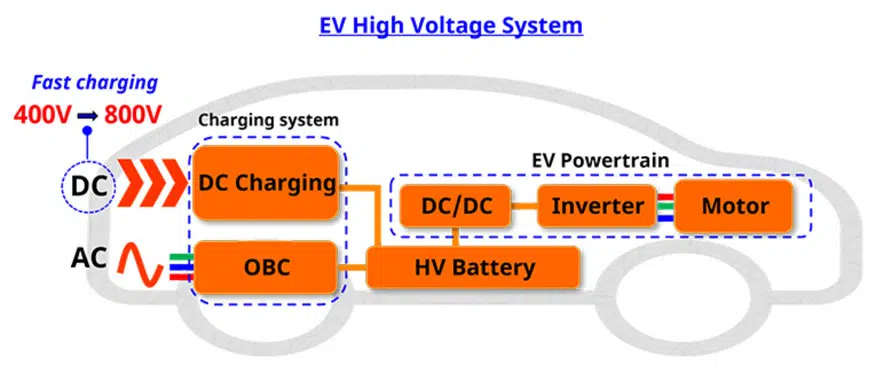

High voltage application in the electric car

The basic powertrain configuration of electric vehicles consists of high voltage battery, inverter, and electric motor. EV powertrains use high voltage . The efficiency of an EV is linked to the efficiency of the DC/DC converter . Electric cars have various power conversion applications such as LDC, OBC, and Inverter. Various DC/DC Converter Topologies are being applied to integrate similar applications. For example, OBC (On Board Charger) and LDC (Low-Voltage DC/DC Converter) are under development for the system integration which have an advantage of reducing components and saving spaces.

High Voltage MLCC structure for guaranteed reliability

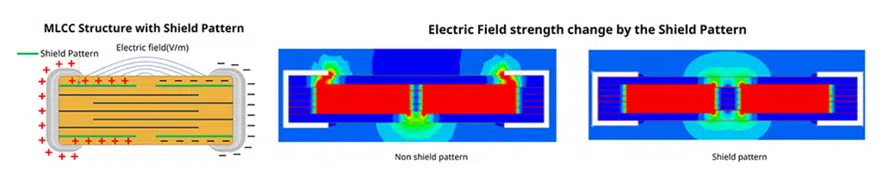

How is the structure of high voltage MLCC different from that of general MLCC? Reliability should be guaranteed in high voltage environments. MLCC applied for high voltage applications are exposed to the risk of Arc-over and a short-circuit can occur inside of the MLCC. Under high voltage, a strong electric field is formed around the MLCC, which ionizes the surrounding air. Particularly, a strong electric field is concentrated on both terminals of the MLCC. If it exceeds the inception voltage of the ionized air, electrical arcs occurs, ultimately leading to a short-circuit inside the MLCC. The structure that prevents this phenomenon is a shield pattern inside MLCC.

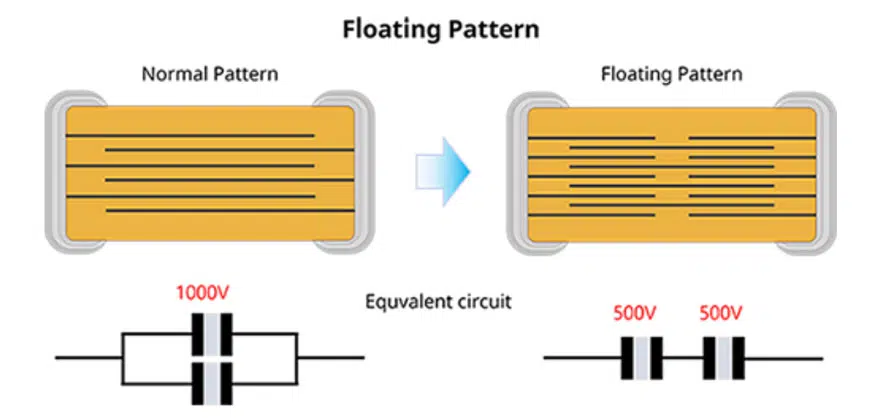

Floating design is a design that lowers the short-circuit risk when MLCC crack occurs, but it is also useful for high-voltage products. The floating structure distributes voltage so the voltage inside the MLCC is only half of the voltage applied to the end terminals. For example, when 1000V is applied to both ends of the MLCC, if the floating design is used only 500V is applied to the MLCC dielectric layer, which is half of 1000V. It’s definitely an advantage from the perspective of reliability because the electric field applied between dielectric layers decreases. Voltage along with temperature are key factors to determine MLCC lifetime. High Voltage MLCC guarantees reliability in high voltage applications.

Samsung EV application video:

Further reading: