Knowles Precision Devices’ white paper, Making Electric Vehicle Wireless Charging a Reality, focuses on how engineers can address wireless EV charging by selecting resonant capacitors designed to ensure the reliability and efficiency.

As electric vehicle (EV) adoption for both consumer and commercial purposes rapidly grows, so does the need for a more widespread, and faster, charging infrastructure. While we’ve seen vast improvements in charging technology in the last few years, as additional regulations on combustion vehicles are implemented and reliance on EVs increases, further EV charging innovations are needed. Currently, wireless charging is the newest EV charging technology evolving.

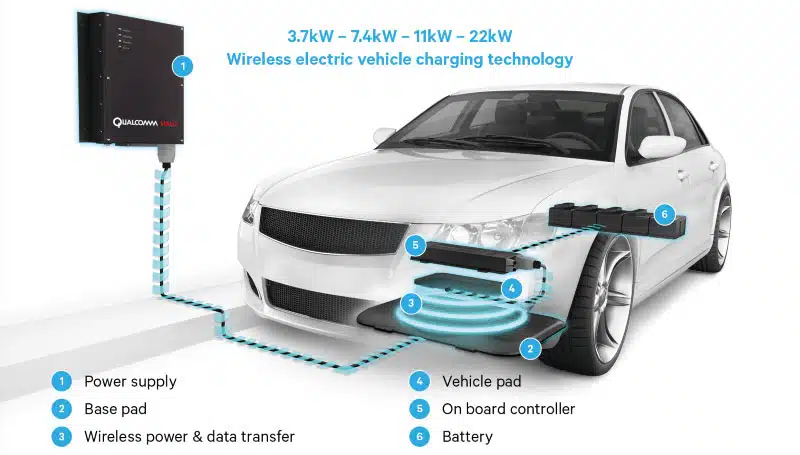

For wireless EV charging, inductive charging is used. This method of wireless power transfer works by creating a magnetic-resonance field between a transmitting pad on the ground that is physically connected to a power source and a receiving pad on the bottom of the EV that is connected to the vehicle’s battery (Figure 1).

But there are a number of challenges associated with developing this type of wireless charging solution for EVs including the following:

- Ensuring interoperability between the wireless charger and the many makes and models of EVs on the markes

- Standardizing components across the wireless receiver and transmitter

- Optimizing wireless power transfer to accelerate charging times

- Keeping costs competitive with wired charging options

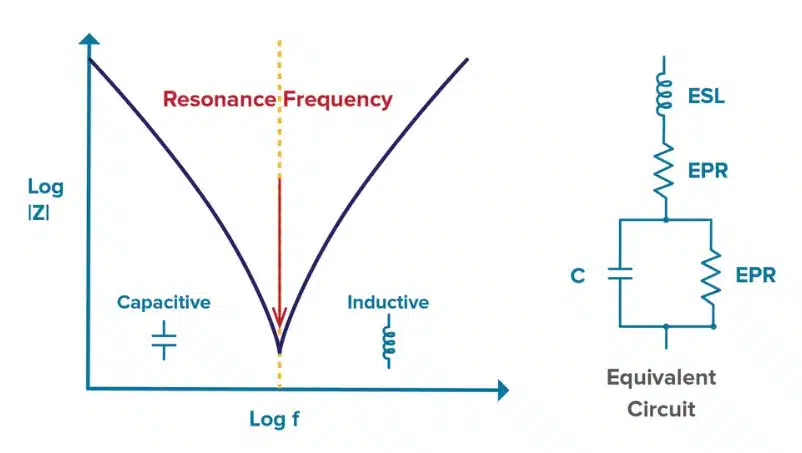

At a foundational level, the ability to store electric charge and more easily pass higher-frequency AC currents are two of the most identifiable properties of capacitors. However, at very high frequencies, the ideal behavior of a capacitor can be compromised. In those situations, the parasitic, resistive and inductive components of a capacitor have an outsized influence on its behavior.

Ideal capacitor math describes a scenario where impedance approaches zero as frequency increases. Real-world testing reveals an application- and component-specific frequency boundary for impedance. At that boundary, the equivalent series inductance (ESL) of the capacitor forms an LC resonance circuit with itself. This is referred to as self-resonance. Up to its self-resonant frequency, a capacitor acts like it’s supposed to—like a capacitor. Beyond this frequency, it starts to act like an inductor, which impedes AC current.

It’s crucial to note that the Q factor of a capacitor typically reaches a minimum at its self-resonant frequency. Q factor, defined as the ratio of a capacitor’s reactance to its equivalent series resistance (ESR), serves as a measure of efficiency, particularly in terms of energy loss. For optimal performance, operations should remain below this frequency.

Resonant capacitors are able to store and discharge energy to achieve specific circuit behaviors that can improve power conversion efficiency, reduce losses, and minimize switching stress.

While resonant capacitor applications today are mainly dominated by film capacitor technology, in this paper, we highlight several reasons multilayer ceramic capacitors (MLCCs), and particularly MLCCs built with our proprietary ceramics, are a much better alternative. We also explore several off-the-shelf and custom resonant capacitor options from Knowles Precision Devices that can help you make your wireless EV charging technology a reality.

Download our white paper, Making Electric Vehicle Wireless Charging a Reality, to learn more about working with Knowles Precision Devices to bring stability and reliability to your wireless EV charging application from the very beginning.