source: Electronics 360 news

New Yorker Electronics has released a new line of products based on the highly customizable Chameleon Concept Magnetics (CCM) Technology. The Exxelia Magnetics CCM technology adapts to most every need, even the harshest environments, including VIGON® resistance.

These ‘chameleon-like’ products can be either an inductor or a transformer depending on the Inductor Ranges. Exxelia designed CCM technology to respond to the growing interest of electronic engineers for inductors and transformers with multiple outputs, high power density and reduced footprints.

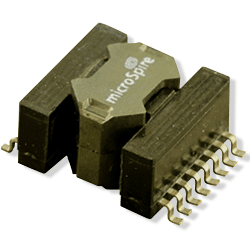

Source: New Yorker ElectronicsThe series offers five different sizes, allowing optimized component design in a pick-and-place surface mount (SMD) package. Through-hole (TH) packages are also available upon request. The CCM series is particularly flexible with a number of pin options available, from 2×6 pins for the smallest package, up to 2×10. Qualified for aeronautic and space applications, the CCM product line features abundant robustness. The monolithic design provides high mechanical performance, proven by the successfully testing in accordance with MIL-STD-202 (methods 213 and 204).

CCM transformers and inductors can operate over a wide temperature range with a minimal temperature of -55°C. The standard thermal grade of the technology is 140°C, and the thermal resistance is 30% lower than standard industrial components. The epoxy molding that protects the winding ensures a lower temperature gradient and improved heat dissipation. Each unit is thoroughly tested with a dielectric withstanding strength of 1,500VAC. Component materials meet UL 94-V0 rating.

Exxelia can evaluate losses and related temperature rise thanks to an in-depth knowledge of CCM technology. Thermal resistance data is available for each package size. Exxelia can also manufacture products in CCM technology according to MIL-STD-981.

New Yorker Electronics is franchise distributor of Exxelia Magnetics (ex-Microspire), part of Exxelia Group, and supplies its full line of Film, Mica, Tantalum, Aluminum Electrolytics and Ceramic Capacitors as well as its EMI/RFI Filters, Magnetics, Position Sensors, Slip Rings and Rotary Joints.

Features & Benefits:

- Designed to withstand severe environment as space & avionics

- Epoxy Transfer molding technology

- SMD package

- Multiple pins

- Ferrite Withstand high shocks and vibration (MIL STD 202 Method 213 & 204)

- Good repeatability of electrical characteristics, allow good regulation of multiple outputs power supply

- Higher power density up to + 30% compared to standard package

- Easy to pick and place

- Flexibility of use

- No stress on the Ferritecore External assembly

Applications:

- Aeronautics and Space

- Common Mode Chokes

- Gate Drive Transformers

- SMD Filtering Chokes

- Current Transformers

- Flyback Transformers

- Forward Transformers

- Push-Pull Transformers

- PFC Chokes