Power applications are generally considered “high current/voltage” applications. There are also two aspects to power applications. The first addresses the issue of Joule, I2R, heating in high current contacts which leads to a possibility of definition of “high” as a current sufficient to cause Joule heating to be taken into consideration. The second addresses how current is distributed through the electronic system, by dedicated high current contacts or multiple low current contacts connected in parallel. Current/voltage considerations will be discussed first.

Voltage/Current Considerations

The current and voltage requirements of an application affect the design, materials and performance requirements a connector must meet to be suitable for the application. It must be noted that current and voltage requirement issues are primarily of concern only in power applications because the currents and voltages in typical signal applications will not give rise to the issues to be discussed. The issues to be addressed are different for voltage and current and will be discussed separately.

Voltage Considerations

Voltage considerations involve primarily the design and materials of the connector housing. The issue is the potential for high voltage breakdown of insulators in the connector. The insulators of concern are air, the space between the contacts in the connector housing, and the housing material, the insulation supporting and separating the current carrying contacts in the housing. In both cases voltage breakdown results in unwanted current flow, arcing between contacts in the case of air breakdown, and arcing or leakage currents through or on the surface of the connector housing. Voltage breakdown has both safety and performance aspects. It is important to note that it is the electrical field between the contacts that causes the breakdown. The electric field is given by the quotient of the voltage divided by the separation between the contacts:

The electric field, thus the breakdown voltage, depends on the spacing between the contacts, a distance that has decreased markedly due to connector miniaturization in recent years.

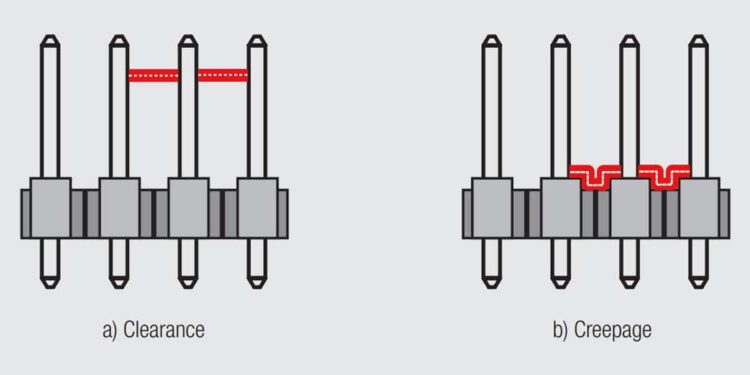

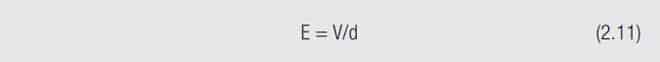

Voltage breakdown concerns are addressed by connector requirements, primarily dictated by safety concerns (arcing), called clearance and creepage distances, illustrated in Figure 2.163. Clearance is the line of sight distance between two power and ground contacts and the clearance requirement is sufficient to ensure that dielectric breakdown of air does not occur. Creepage is the shortest distance along the housing surface between the two points where adjacent power and ground contacts are retained in the housing. The creepage requirement is intended to put limits on the degradation of the surface resistance of the connector housing material in the conditions, chemistry and humidity of the application environment. Voltage breakdown of the bulk housing material, the walls between contacts, is seldom a concern.

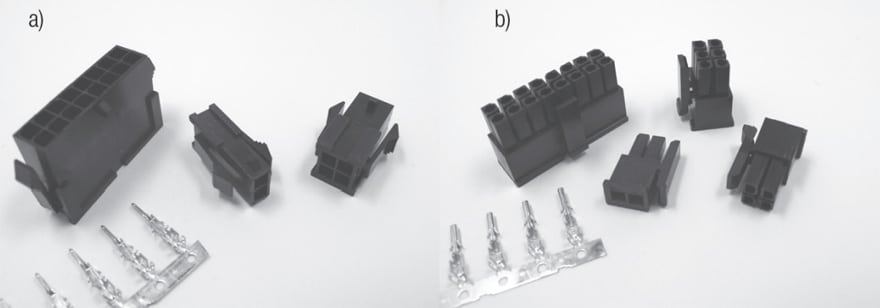

Another safety related impact on connector housing design is to provide barriers around the contacts to prevent inadvertent contact of external conductors or body parts, primarily fingers, to the hot side of the connector. Such protection is often referred to as “finger proofing”. Two modes of protection are common, recessing of contacts within the housing and silos surrounding the contacts. Examples of recessed and siloed contacts are provided in Figure 2.164a and b respectively.

Current Considerations

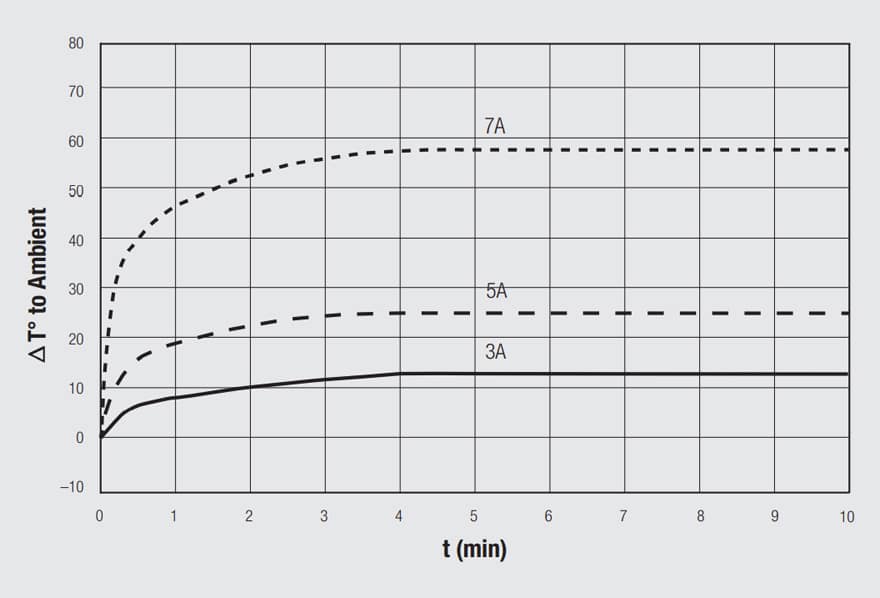

The major concern relative to current, as noted, is Joule, I2R, heating. The I2 dependence indicates that higher current, i.e. power applications, are particularly sensitive to Joule heating and the associated temperature increases. As noted at several points in this text, temperature contributes to acceleration of many connector degradation mechanisms including corrosion, stress relaxation and, in worst case situations, degradation, including melting, of connector housings. Joule heating is particularly problematic in that it creates a positive feedback loop due to the positive temperature coefficient of resistivity of copper alloys. All of the components of resistance in a connector, permanent connection, separable interface and bulk resistances (Chapter I/1.3.3 The Electrical Interface: Contact Resistance) include the resistivity of contact spring material as a parameter. Thus all of these resistances increase with temperature. The increase in resistance results in an increase in Joule heating and the loop continues. A schematic illustration of the T-rise of a connector as a function of current is provided in Figure 2.165. Briefly, a T-rise measurement is generally made by attaching a thermocouple to the “hot spot” on the contact prior to testing. A selected current is applied, maintained and the temperature of the contact is measured periodically. The test is ended when the temperature has stabilized with time. IEC 60512-1 Part 3-1 Test 5a is a standard for T-rise testing.

This consequence of Joule heating is addressed by application of temperature rise, T-rise, limits on connectors in power applications. One such commonly accepted T-rise limit, used to current rate connectors, is a 30 degree C increase in temperature. Power contact current rating will be discussed in the following sub-chapter.

It must be noted that PCB traces may greatly affect temperature rise in Wire To Board applications therefore any general comment must always be proof checked in real conditions/applications.

Two aspects of power contact/connector applications will be reviewed; contact/connector current rating and the distribution of current within an electronic system. Two approaches to current distribution will be discussed, the use of dedicated high current contacts and the use of multiple lower current capacity contacts in parallel in a connector housing.