Recent advances in smart contact lenses can assist biomedical engineers to realize medical applications and vision imaging for augmented reality with wireless communication systems. Center for Nanomedicine and Department of Engineering in Korea, described a human pilot trial for smart contact lenses with a wirelessly rechargeable, solid-state supercapacitor for continuous operation.

Previous research on smart contact lenses were driven by a wireless system or wireless power transfer with temporal and spatial restrictions. Such power sources can limit their continuous use and require energy storage devices. The rigidity, heat and large battery size are also less suited for soft, smart contact lenses.

In a new report on Science Advances, Jihun Park and a research team in the departments of Materials Science and Engineering, Center for Nanomedicine and Department of Engineering in Korea, described a human pilot trial for smart contact lenses. They engineered the lenses with a wirelessly rechargeable, solid-state supercapacitor for continuous operation. The research team printed the supercapacitor and integrated all device components, including the antenna, rectifier and light emitting diode using stretchable structures to form the soft lens without obstructing vision. The device was reliable against thermal and electromagnetic radiation, with promising test results in vivo and substantial promise for smart contact lenses in the future.

Advances in wearable electronics have allowed biomedical researchers to monitor physical signs and metabolites in human body fluids. Smart contact lenses can be extensively studied as a new platform to continuously monitor vital signs in the eyes and within tears to investigate biomarkers associated with disease. The lenses can also offer expanded applications in other areas such as smart devices for drug delivery and augmented reality.

The softness of smart contact lenses is essential for the user’s comfort across long periods of time during intermittent wireless operation. The rigidity, heat generation and battery size had made preceding lenses less suited to function as required. To address existing limits, Park et al. introduced a new approach to engineer a soft, smart contact lens with a wirelessly rechargeable solid-state supercapacitor for continuous operation of the electronic device.

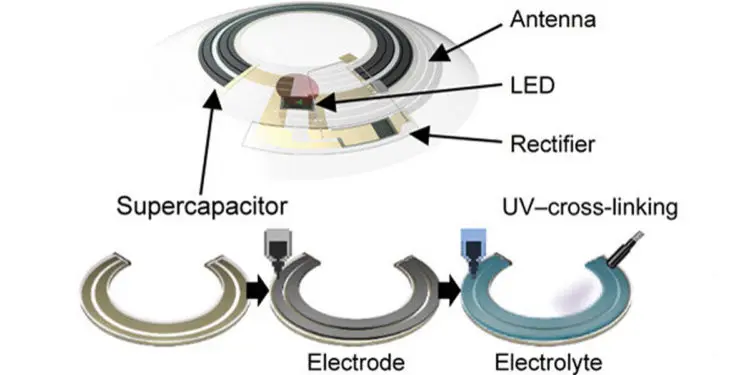

First, they formed an activated carbon-based, solid-state, electric double-layer supercapacitor using a high-precision, microscale direct ink writing (DIW) process to create the smart contact lens. Supercapacitors typically exhibit long life cycles and high-power density for consistent wireless charging and discharging operations of ingrained electronic devices within smart contact lenses. The supercapacitor in this work also served as a physical support during 3-D layer-by-layer integration with accompanying electronic circuits and antenna to form the wireless charging system. This was a challenging step due to the limited area of the smart contact lens.

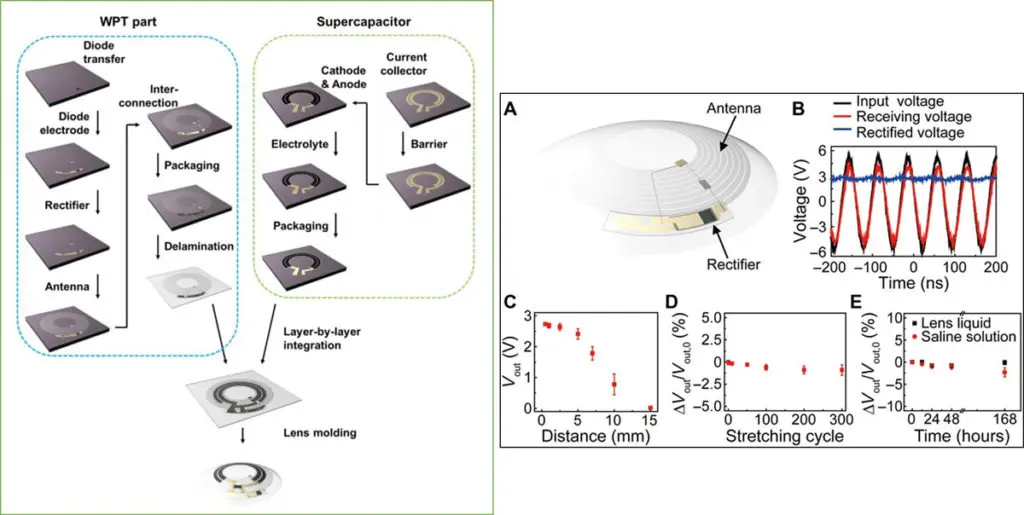

Park et al. combined the wireless charging system with the solid-state supercapacitor to facilitate continuous and repetitive operation of the smart contact lens without an external electric port. To construct stretchable geometries for the antenna, the researchers used hybrid nanostructures of ultrastrong silver nanofibers (AgNFs) and fine silver nanowires (AgNWs). Additionally, they used a stretchable hybrid substrate composed of rigidly reinforced islands and a soft matrix to improve endurance of the brittle components of the contact lens against mechanical deformation.

The system displayed superb endurance after 300 cycles with a biaxially tensile strain of 30 percent. The smart contact lens maintained high softness and comfort without obscuring the vision of the wearer, while protecting electrical devices from tear across a seven-day timeline. The wireless charging system avoided abrupt heating to protect the wearer’s safety. A human pilot trial and in vivo translational studies in live rabbits further verified the biocompatibility of the lens.

Park et al. combined the wirelessly chargeable solid-state supercapacitor with the rectifier circuit, antenna and light-emitting diode (LED) within the layout of the soft, smart contact lens. They included a wireless power transfer (WPT) unit in the upper layer of the smart contact lens and the lower layer contained the solid-state supercapacitor to repeatedly store and use electric power. The research team integrated the LED as an indicator to detect wireless operation of the smart contact lens.

The arc-shaped form factor secured maximum energy density within the limited areas of the contact lens allowing deformability when stretched. To prevent interference with the wearer’s field of vision, the team designed the smart contact lens to contain all components outside of the wearer’s pupil. They also included an in-plane electrode configuration to minimize abrupt failure of the internal short circuit. Park et al. observed the resulting electrodes and solid-state electrolyte prepared using the DIW (direct ink writing) process with scanning electron microscope (SEM) images.

The research team printed the arc-shaped, monolithically integrated solid-state supercapacitor (MIS-supercapacitor) directly to form the smart contact lens while introducing a parylene-based packing layer to prevent leakage of the constituent material into the eyes. The supercapacitor showed reasonable cycling performance combined with the wireless charging system for long-term use. The study formed a first report on a power source-integrated smart contact lens with sustainable electrochemical performance.

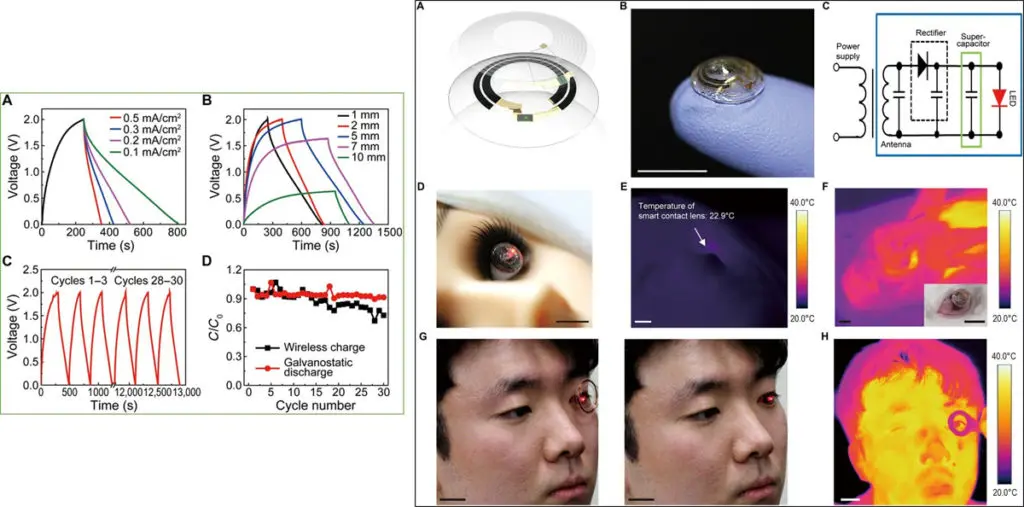

Park et al. then engineered the wireless power transfer (WPT) circuit to charge the supercapacitor. The underlying WPT circuit displayed good mechanical stretchability and chemical stability to endure a variety of stimulations. The circuit had negligible degradation in its electrical performance even during its stretching state—suited for flexible and soft contact lenses. The research team characterized the supercapacitor and WPT system using wireless charging/galvanostatic discharging processes and charged the supercapacitor in full using wireless charging conditions within a relatively short time (240 seconds). The wireless system provided reliable performance across multiple cycles for smart contact lenses—suited for long-term use.

The completed soft contact lens system thereby contained a wirelessly rechargeable supercapacitor, antenna, rectifier circuit and LED united in stretchable form. After assimilating the layers, the scientists encapsulated the electronic components in a silicone elastomer as a commercially available soft contact lens material molded into the shape of a contact lens. When driven wirelessly, the embedded LED indicated the status of wireless charging and discharging.

The research team first tested the device on the eye of a mannequin and monitored heat generation during wireless operation of the lens using an infrared (IR) camera. The results indicated reliability of the smart contact lens against thermal or electromagnetic radiation. During in vivo translational tests, the researchers facilitated the contact lens onto the eye of a live rabbit for reliable operation without noticeable side effects or abrupt heat generation. During subsequent human pilot trials on a human eye, Park et al. tested all functions including the wireless charging/discharging operation of the supercapacitor and LED. The results were feasible with wireless functionalities as expected and without adverse reactions.

In this way, Jihun Park and colleagues engineered a soft, smart contact lens to charge a supercapacitor wirelessly for continuous function. They embedded the electronic components including a stretchable antenna, rectifier circuits, LEDs and a supercapacitor to form the soft, smart contact lens without obstructing the wearer’s view on use. They conducted many stability tests for long-term use of the soft, smart contact lens. The pilot studies in humans and translational studies with live rabbits verified good biocompatibility. The research team expect to use the platform as a miniaturized, wearable electronics device with continuous function.