Rheinmetall sets up joint venture with US specialist PolyCharge America, Inc. to produce, develop and market DC-link capacitors for e-mobility and green energy applications in Europe.

As part of its electrification strategy, the Düsseldorf-based tech enterprise Rheinmetall is setting up a joint venture with the US start-up PolyCharge America, Inc. to produce, develop and market DC-link capacitors. Underlying this move is the Group’s goal of gaining a stronger foothold in the rapidly growing markets for electromobility and industrial applications as well as accessing subsystems and components necessary for making innovative products in future.

Known as Rheinmetall PolyCharge GmbH, the new joint venture company is majority-owned by Rheinmetall (75%). The remaining 25% stake is held by PolyCharge. In this constellation, Rheinmetall is responding to growing demand for e-mobility and green energy components, especially in the automotive parts sector but also from its military customers.

In the Rheinmetall PowerPack system for electrically powered vehicles, now in development, advanced DC-link capacitors from PolyCharge play an important role. Owing to its improved efficiency and range, Rheinmetall sees strong market potential and scope for growth for the new power pack solution.

In this close operational partnership with PolyCharge, the joint venture will have exclusive rights to produce and market NanoLam capacitors in Europe.

To underpin its close cooperation with PolyCharge, Rheinmetall has simultaneously taken up an approximately 13% share in the Tucson, Arizona-based company. Both parties have agreed not to disclose the financial dimensions of the transaction.

“The founding of this joint venture marks another important step in our transformation strategy, enabling us to offer our customers in the automotive and industrial sector top electrification technology as we move forward”, stated Rene Gansauge, chief executive of Rheinmetall’s Sensors and Actuators division. “Advanced NanoLam technology lets us offer a product that’s substantially smaller and lighter than the conventional solutions, and which can operate at higher temperatures. This is a clear technological advantage, assuring that Rheinmetall PolyCharge is well positioned to meet the growing demand for these technologies.”

“Diversifying PolyCharge’s manufacturing base is crucial as we transition to high-volume production of NanoLam capacitors for automotive, aerospace, and industrial markets,” said Steven Yializis, chief operating officer of PolyCharge America. “Rheinmetall’s technical depth, application expertise, and strong presence in Europe make it an ideal partner, allowing for rapid expansion in this important and growing market,” added Mr. Yializis.

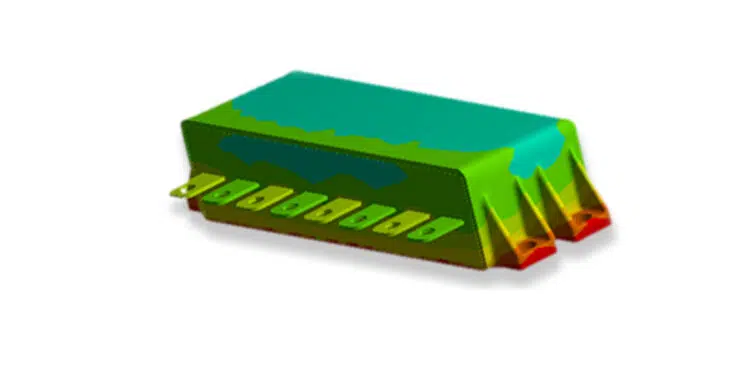

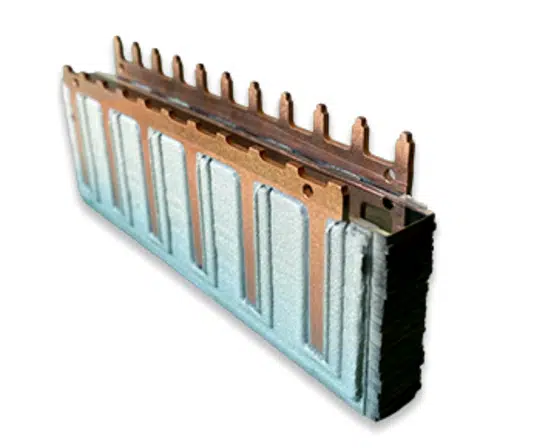

The new PolyCharge capacitors with nanolaminate technology feature sub-micrometre-thin, dielectric polymer coatings that enable optimum cooling and improved performance.

PolyCharge is a technologically leading supplier of these components, whose chief advantages are thermal stability, longevity and high output density.

In future, the activities of the majority joint venture will be domiciled in Rheinmetall’s Sensor and Actuators division, which is spearheading the company’s electrification strategy and now implementing advanced developments in the “Beyond Automotive” and industrial domain.

PolyCharge: A company with trailblazing capacitor technology

PolyCharge is an American company founded by Sigma Technologies to market its innovative NanoLam technology. The company employs a staff of 15 at its corporate seat and production location in Tucson, Arizona in the United States.

PolyCharge’s product range encompasses forward-looking solutions for the electromobility and renewable energy sectors as well as medical, aerospace and industrial applications.

Polycharge Nanolam Capacitors Key Features:

Superior Energy Density

Sub-micron, self-healing, polymer dielectrics result in capacitors with energy density greater than 100x when compared to polypropylene film capacitors with voltage ratings ranging from 48-volts to thousands of volts. Nano-layer dielectrics reduce weight by as much as 90% when compared to multi-layer ceramic capacitors.

High Temperature

Thermoset dielectrics are formulated to withstand temperatures from -196ºC to as high as 200ºC making NanoLam™ capacitors ideal for applications typically dominated by multi-layer ceramics, tantalums, and high temperature films. Cooling requirements for the capacitor are either reduced or eliminated.

Stable Performance and Long Life

PolyCharge NanoLam™ capacitors exhibit stable capacitance, breakdown strength, and equivalent series resistance (ESR) across a broad temperature and frequency range with lifetimes measured in hundreds of thousands of hours.

Dynamic Form Factor

NanoLam™ capacitors are prismatic in shape making them ideal for applications with challenging fit requirements. It also allows for higher surface area designs for greater heat dissipation.

Ideal for SiC and GaN Systems

Superior energy density, high temperature handling capabilities, stable capacitance, and low ESR and ESL make PolyCharge NanoLam™ capacitors ideal for wide band gap architectures – with the ability to mount the capacitor closer to the power module resulting in lower inductance and greater efficiency.