As noted previously, the environmental exposures for non-noble (tin) and noble (gold) plated contacts are different. The dominant degradation mechanism for tin connectors is fretting corrosion, a build-up of oxide debris at the contact interface due to small scale motions (tens of microns). The oxidation of tin is a given and the degradation process is dominated by the mechanical stability of the contact interface with respect to inhibiting fretting motions. Tin corrosion exposures are predominantly temperature-humidity related and there is no generally accepted correlation between such exposures and field performance.

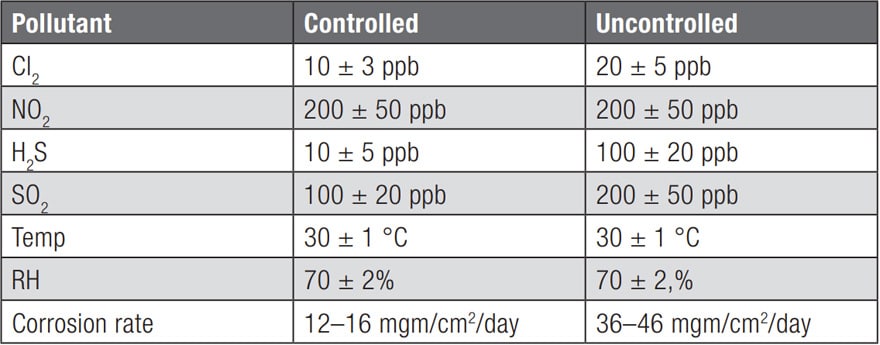

The situation with noble metal finishes, in particular gold over nickel, is very different. There were a number of investigations into the environmental stability of gold contact finishes in the ‘70s and a significant amount of data relating test environments to field performance was developed. The details of these studies are outside the scope, but suffice it to say that there are two test environments that are generally accepted as indicative of field performance. As shown in Table 2.9, taken from EIA 364 TP 65 they are:

While other test environments are specified, they have in common the important pollutants, Cl2, NO2, H2S and SO2, and the low level of pollutant concentrations, parts per billion and the temperature and humidity levels.

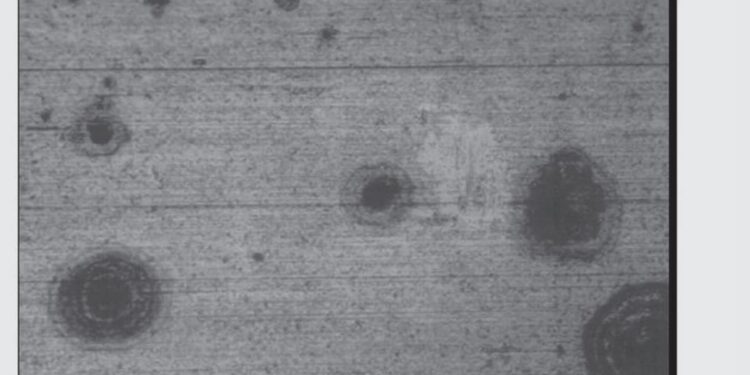

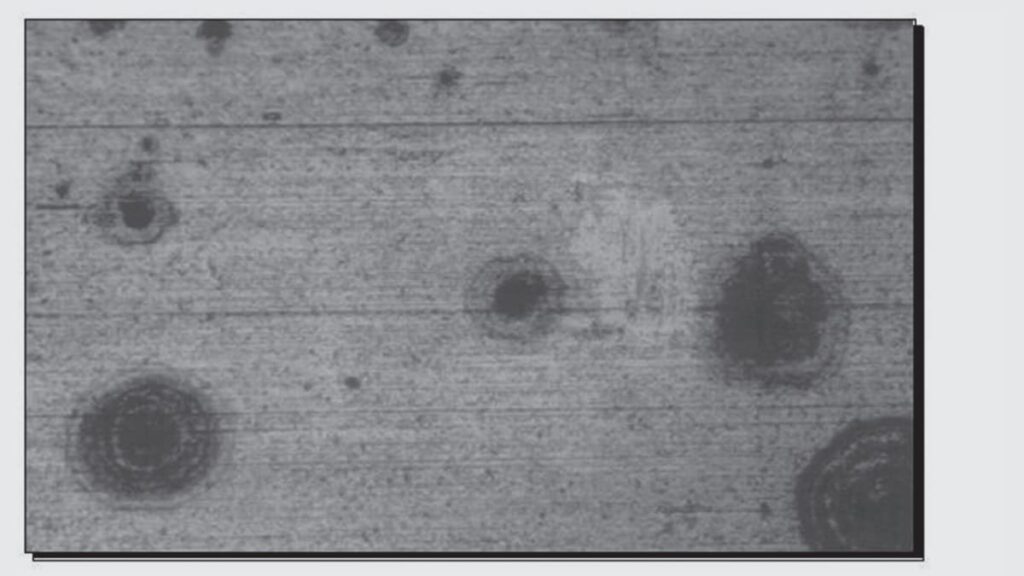

Some of the major findings about noble metal corrosion in mixed flowing gas environments are suggested in Figure 2.120 and 2.121.

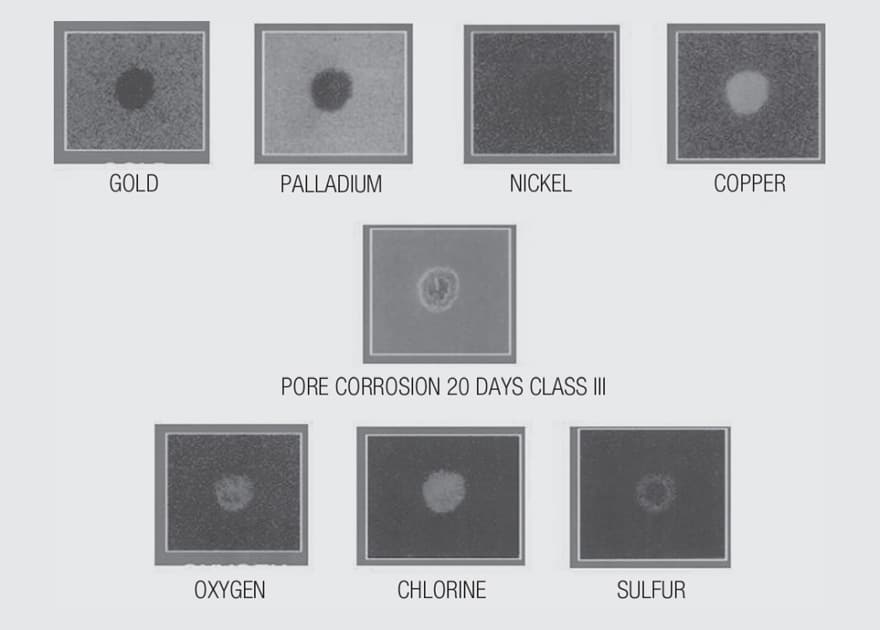

First, Figure 2.120 illustrates pore corrosion and the migration of corrosion products from the pore sites over the contact surface, the rings around the pore sites. The corrosion source, in all cases, is the copper alloy of the contact spring. The corrosion products that are migrating are identified in Figure 2.121. The X-ray maps shown in Figure 2.121 show that the

contact finish under test was a gold flash over nickel over copper alloy. The pore site in this case originated at the copper alloy as indicated by the intensity of the copper signal at the upper right in the figure. The corrosion products, the lower row of X-ray maps consisted of copper, oxygen, chlorine and sulfur. The corrosion synergy between chlorine and sulfur distinguishes mild from harsh environments. Note the difference in corrosion rates between the controlled and uncontrolled environments and the chlorine and sulfur concentrations in Table 2.9. The corrosion rates are, in fact, used to validate the exposure by measuring the sample weight gain. There are acceleration factors for these two environments with a two day exposure to the test environment being equivalent to a year of exposure in the field environment.