This article is based on newsletter written by Pablo Blázquez, Frenetic power electronics engineer that explores how the choice of Magnetic Core materials plays a key role in determining the performance and efficiency of Inductors and Transformers.

Engineers working with Magnetic components must consider various factors, including the type of material, core shape, customization possibilities, and even the influence of different wire types.

Magnetic Core Materials

Let’s discover the world of Magnetic cores, with a focus on ferrite, powder, amorphous and electrical steel, while also considering the impact of wire types such as round, litz, planar, cu-stamps, foil and rectangular wire.

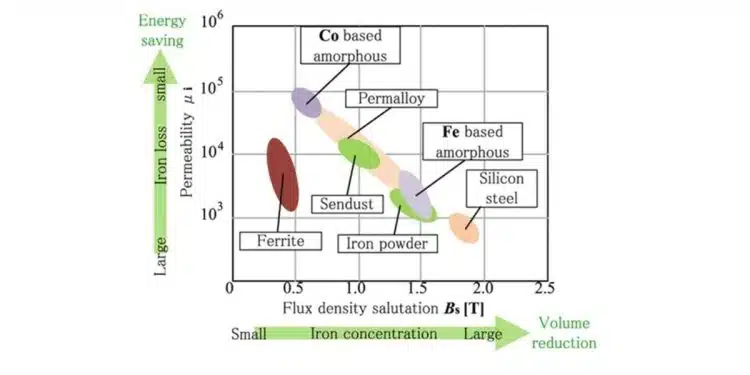

Ferrite cores, composed of ceramic materials with iron oxide, are popular choices in Magnetics design. They present high resistivity, making them suitable for high-frequency applications. Ferrite cores are known for their stable Magnetic properties and are widely used in power supplies, Transformers, and Inductors. Their low losses at higher frequencies contribute to enhanced efficiency.

Powder cores consist of a mixture of iron powder and insulating material. These cores strike a balance between the characteristics of ferrite and iron powder cores, offering improved efficiency and inductance stability. The customizable nature of powder cores allows for tailoring designs to specific application requirements.

Amorphous cores are crafted from materials lacking a defined crystalline structure. This unique composition results in reduced core losses, making amorphous materials ideal for applications demanding high efficiency. These cores find applications in power transformers where minimizing energy losses is crucial.

Electrical steel, specifically designed for Magnetic applications, is a common material for Transformer cores. Its low core loss and high permeability make it suitable for low-frequency applications. Engineers often choose between grain-oriented and non-oriented electrical steel based on specific design requirements.

Core Shapes and Customization

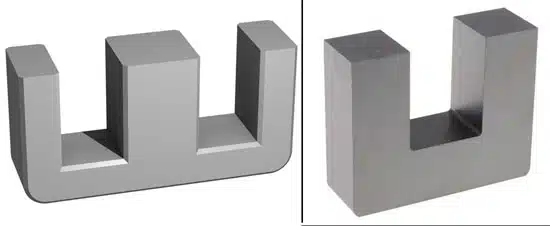

Beyond material considerations, the shape of the Magnetic core also influences performance. Common core shapes include toroidal, E-shaped and U-shaped cores.

Toroidal cores, with a donut-like shape, provide a closed Magnetic path, minimizing leakage flux. This design enhances inductance and allows for efficient energy transfer. Frenetic’s customization capabilities enable engineers to tailor toroidal cores to precise specifications, optimizing performance in diverse applications.

E-shaped and U-shaped Cores are prevalent in Transformer designs, offering advantages in terms of magnetic flux distribution. Frenetic’s expertise lies in customizing these core shapes to meet specific requirements, whether it’s optimizing winding configurations or minimizing magnetic losses.

Wire Types and Their Influence

The choice of wire in Magnetics design further shapes the performance characteristics of Inductors and Transformers. Here’s a look at different wire types and their impact:

Round wires are the most traditional and cost-effective option. While suitable for various applications, they may pose challenges in high-frequency designs due to skin effect.

Litz wire addresses the limitations of skin effect by incorporating multiple thin strands. This design reduces losses at higher frequencies, making it an excellent choice for applications with increased switching frequencies.

Planar, Cu-stamps, Foil, and Rectangular Wire offer unique advantages in terms of reduced proximity effect, enhanced heat dissipation and improved power density. Customizing wire types based on application requirements allows engineers to fine-tune the magnetic component for optimal performance.

The world of Magnetic cores is rich with choices, each with its own set of advantages and considerations. Frenetic’s commitment to digitalized design processes and rapid manufacturing empowers engineers to navigate this complexity efficiently.

By understanding the characteristics of magnetic core materials, shapes, and wire types, engineers can make informed decisions to achieve enhanced performance and efficiency in their power electronics applications.

Innovations in Core Design

Advanced Core Materials

In the pursuit of even greater efficiency and performance, engineers are constantly exploring innovative materials for Magnetic cores. Frenetic’s commitment to staying at the forefront of these developments ensures that our clients benefit from the latest advancements.

One notable development is the use of nanocrystalline materials in core design. These materials exhibit remarkable magnetic properties, including high permeability and reduced core losses. Frenetic is actively incorporating nanocrystalline cores into our repertoire, pushing the boundaries of what is achievable in terms of power electronics efficiency.

Tailoring Cores for Unique Applications

While standard core shapes meet the requirements of many applications, some projects demand a more customized approach. Frenetic’s capabilities extend beyond the conventional, allowing engineers to specify unique core geometries to achieve optimal performance.

- For example, in certain applications, a three-dimensional core design may be more suitable than traditional two-dimensional shapes. Frenetic’s engineering team collaborates with clients to explore and implement three-dimensional core configurations, maximizing magnetic flux control and minimizing losses.

- Hybrid Core Configurations combine different core materials in a single design, another avenue for customization. Engineers can leverage the unique properties of each material to achieve a balance of performance characteristics. Frenetic’s expertise in this area empowers clients to create Magnetic components that precisely align with their project requirements.

- Recognizing that the interaction between the core and winding is crucial for optimal performance, Frenetic places a strong emphasis on the selection and customization of wire types. The synergy between core material and wire type contributes significantly to the overall efficiency of the magnetic component.

- Finally, Frenetic engineers are exploring advanced winding techniques to optimize the interaction between the core and wire. This includes precision winding processes that reduce the proximity effect and improve overall winding efficiency.

Conclusion: A Future of Possibilities

As we navigate the landscape of magnetic core design, it becomes evident that the future holds exciting possibilities. Frenetic’s commitment to innovation and customization ensures that our clients have access to cutting-edge solutions that push the boundaries of what is achievable in power electronics.

In the coming years, we anticipate further breakthroughs in materials, core shapes, and wire technologies. Frenetic is poised to lead the way, providing power electronics engineers with the tools and expertise needed to stay at the forefront of this dynamic field. The significance of materials in magnetic core design is not merely a consideration but a cornerstone of achieving unparalleled performance and efficiency in power electronics applications.