In this blog article Sotiris Zorbas, MSc, Frenetic power electronics engineer, suggests USB PD 3.0 compatible flyback transformer optimisation, and how to select the best fit core type using the Core Optimizer™️ tool in Frenetic Magnetics design software.

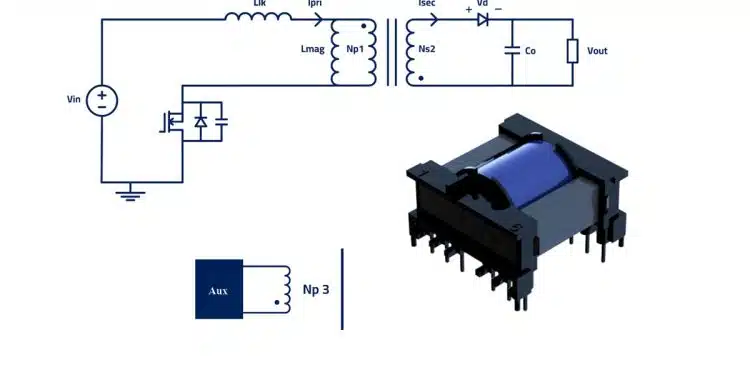

Let’s consider the drawbacks of flyback transformer designs as in example of Frenetic EQ25 design (Figure 1.):

1. Flying leads at the secondary side

For those of you that haven’t heard of this before, that’s just one design choice when we have a winding ending. There are two options:

- Terminate the wire to the coil former pin.

- Leave some cm of extra wire to solder it directly to the PCB. Although this might seem like a simple design choice, the truth is that doing so creates extra manual labour when it comes to the assembly of the PCB board the flyback transformer will be mounted on to. Human intervention is costly!

Question: Why do we need flying leads in the first place?

Answer: There are a couple of reasons to go for flying leads. In low power transformers/inductors, the reason is high voltages. For a transformer to pass safety standards and be safe to use, many times the distances of the pins between themselves, or with respect to the core, are not enough. For high power applications, the current levels resulting in the use of big wire dimensions create mounting issues. Up to certain wire dimensions things are simple, and the wires can be soldered to the pins. After a point though, that is not an option anymore and flying leads is the decision to go for.

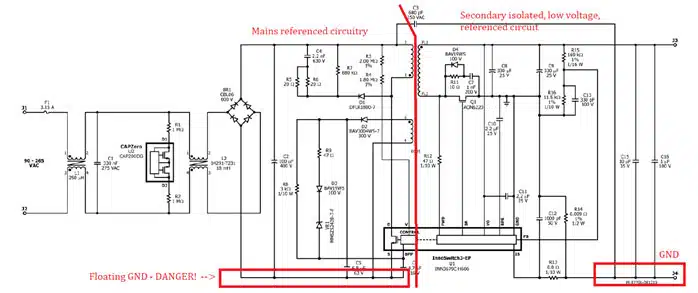

For the flyback design we’re analysing, the problem is high voltages (up to 375VDC in the primary side). Reinforced insulation was selected and, based on IEC61558-1 automotive standard, >6mm of creepage distance is necessary to pass regulation. The EQ25 design shown in Figure 1 can’t pass the standard, if we terminate the secondary winding to the pins, so flying leads are necessary here.

2. Insulating tape for the core (externally)

Just to remind the situation here, the core itself is made of ferrite. We have a primary and a secondary winding. We insulate the primary and/or the secondary to achieve isolation, comply with the standards and pass Hi-pot testing. But the core itself is considered an electrically conductive material, unless coated with insulation, which is not the case with ferrites.

Therefore, we have a conductive material between isolated windings. The transformer will develop some potential if left floating. A solid design choice is to ground the core, either from it clips or by using some copper tape. Conducted EMI is lowered with this design choice.

Question: At which ground should I ground the core?

Answer: We have 2 grounds in USB-PD 3.0 flyback design. The input ground (which is floating – lethal voltages!) and the output ground (safe to touch). Electrically I don’t find a very good reason why grounding the core to one of the grounds is a better option. But I do find that grounding the core at the secondary – safe to touch – ground is a much better option for obvious reasons!

Without getting into more details, I’ll say that the wire insulation choices at the primary-secondary will either leave the core grounding options open or limit us to a specific choice.

That is the drawback of the EQ25 design. Grounding the core at the secondary side is not allowed, and we are forced to ground the core on the primary side ground. Insulating tape all around the core is needed, being careful to completely cover the ferrite core.

3. Available coil formers.

Unfortunately, the EQ family is not a standard part. EQ cores are planar cores, and that limits the options of coil formers significantly.

Planar cores are called that way because they are designed for planar transformers. That does not exclude them from the classic coil former style approach. The reverse is also applicable. We can design a planar transformer using standard cores. What’s the price of these choices? Availability issues and a limited range of components choices.

The improved design

Assuming the problems of the previous design, I decided to work on a better version, trying to respect most specs of the previous design to be compatible. The design goals of the new transformer are:

- No flying leads (solve drawback No1)

- Core can be grounded on the secondary side ground (solve drawback No2)

- Standard core (solve drawback No3)

- Maximum power raised at 100W (previous design at 60W)

Let’s focus now on the core selection process. Other aspects of the design will be discussed in the next Newsletters, so stay tuned!

To start the design, I used the Core Optimizer™️ feature of our magnetics design program. This new powerful tool available in Frenetic Online is helping engineers find the appropriate core for a particular application without having to rely on experience and empirical formulas.

Step 1. Decide on the core family/dimensions

As shown in Figure 3, different families of cores were plotted in a volume-primary turns graph. Using height as the deciding factor, I selected the ETD29/16/10 core. To be honest, other similar high options were also available, but they were excluded because of insulation reasons, that have to do with the non-flying lead design choice, made for this design.

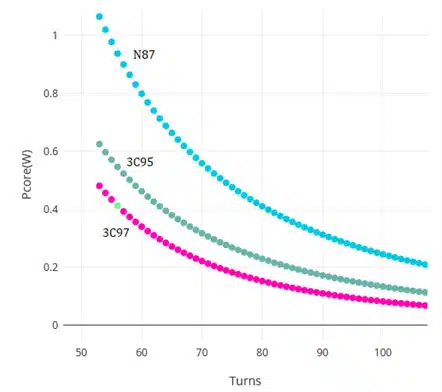

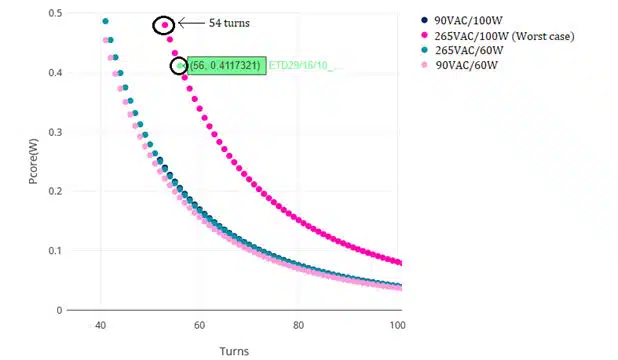

Having the ETD29/16/10 core in mind, I moved on to the second graph of the Core Optimizer, that gave me a clear perspective of the core losses under different operating conditions (worst case scenarios).

Step 2. Decide on the core loss target

Core loss target set at <0.5W. Three core materials were selected (for ETD29/16/10). Plotting the core losses under the same operating conditions (worst case scenario), we got the following graph shown in Figure 4.

We see a difference of ~0.1W between 50-100 turns for 3C95-3C97. That’s not a lot and both materials could be used. On the other hand, N87 material is not a good option here, having almost x2 power losses. So I picked the 3C97 material.

Step 3. Decide on the number of turns

In Figure 5, having selected 3C97 material, the core losses are shown for different operating conditions. The worst-case scenario, as far as the core losses are concerned, is the combination of 265VAC input voltage and output power at 100W. Selecting 54 turns would be ok for losses <0.5W, but in the end I chose 56 turns to make sure the turns ratio (Np/Ns = 7) would result in an integer number of secondary turns.

The New ETD29 Transformer Design

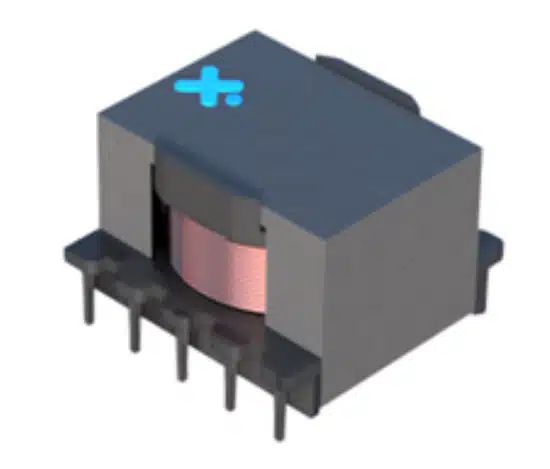

You can have a look now at the new ETD29 transformer design in Figure 6. and online with details here.

The table 1. shows the specs and differences between the old and new design.

References

[1] Applications Engineering Department, “Reference Design Report for a 65 W Power Supply Using InnoSwitchTM3-EP PowiGaNTM INN3679C-H606”, Power Integrations