This article by Dr. V. Azbel, an Independent consultant on tantalum capacitors, summarizes impact of shrinkage and yield strength for controlling of sintered tantalum pellets and quality of tantalum capacitors.

Shrinkage and yield strength are crucial parameters for controlling sintered pellets, but they have distinct limitations.

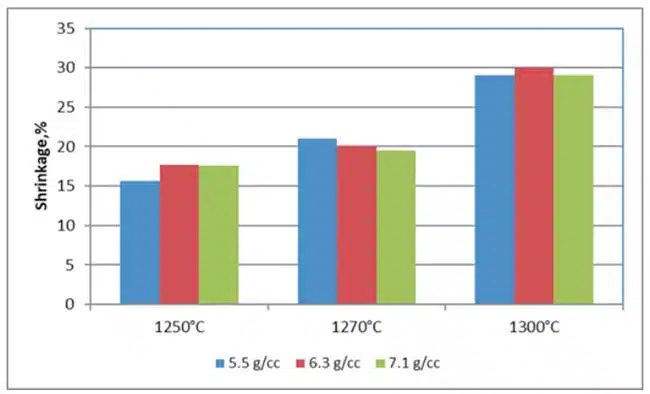

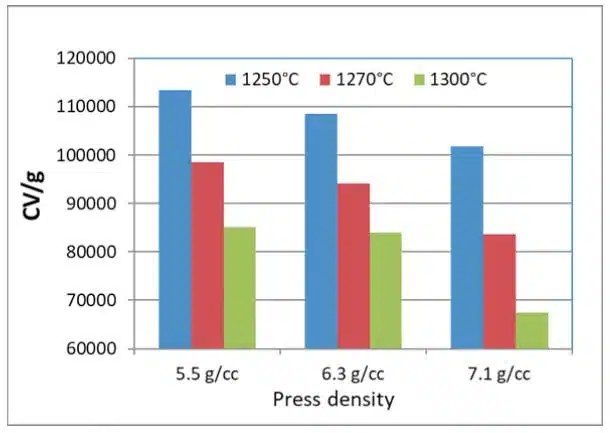

While shrinkage, traditionally used to assess sintering in tantalum capacitor production, doesn’t always accurately reflect changes in the material’s porous structure during sintering, as evident from Figure 1, it lacks a correlation with changes in the anode’s CV/g at the same forming voltage for sintered tablets with different pressing densities but the same temperature.

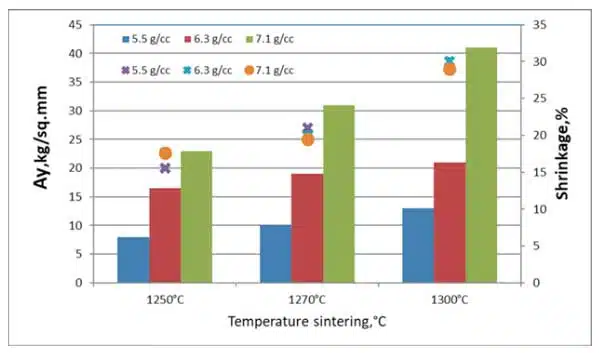

In contrast, the yield strength of the porous material, as shown in Figure 3, is closely linked to variations in its morphology, influenced by both pressing density and temperature. This makes it a valuable tool for controlling the material’s properties.

The graph demonstrates that increasing pressing density at a constant sintering temperature does not affect shrinkage. Shrinkage, however, increases with rising temperature.

This graph illustrates how the CV/g value of an anode made from the same powder changes with sintering temperature and pressing density. The results show that increasing pressing density at a constant temperature decreases CV/g, while shrinkage remains constant.

The graph shows that yield strength increases with higher pressing density at a constant temperature, whereas shrinkage remains unchanged. These findings confirm that yield strength more reliably reflects morphological changes in the porous structure than shrinkage.

Key Takeaways:

- Limitations of Shrinkage Shrinkage is insufficiently precise for sintering evaluation. Even with significant changes in shrinkage, mechanical properties like yield strength may display different trends.

- Correlation with Quality Yield strength is directly linked to the morphology of the porous structure, particularly pore neck size. This enables a more accurate assessment of the sintering process and the identification of defects that might not be apparent when analyzing shrinkage alone.

Recommendations:

To improve the quality control of sintered pellets, it is recommended to incorporate mechanical tests, such as yield strength measurement, into standard evaluation methods. This approach will provide deeper insights into material conditions and facilitate optimizing pressing and sintering parameters, ensuring the best possible characteristics for tantalum capacitors.