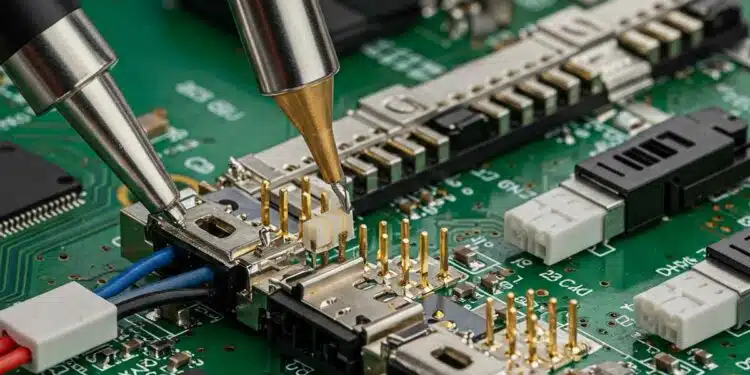

Samtec in its blog compiled ten essential tips for discrete wire assemblies. These guidelines will improve the durability and performance of discrete wire assemblies while minimizing rework and troubleshooting.

When working on reliable discrete wire assemblies, precision and attention to detail are critical to ensuring performance and longevity.

Even small mistakes—such as improper cable routing or excessive force during assembly—can lead to performance issues, mechanical failures, or long-term reliability concerns. Following industry standards like IPC/WHMA-A-620 and using the right techniques can help ensure a successful, high-quality assembly.

1. Optimize Cable Length and Management

Optimize Cable Length and Management: Ensure adequate cable length for routing and movement to prevent undue strain. Avoid aggressive zip ties or routing cables around sharp edges, which can degrade insulation and impact performance.

2. Respect Minimum Bend Radius

Respect Minimum Bend Radius: Follow manufacturers’ recommendations for minimum bend radius and maintain a safe distance from connectors before starting a bend. Tight bends near terminations can create mechanical stress, leading to electrical or mechanical failures.

3. Proper Handling During Modifications

Proper Handling During Modifications: Many customers purchase single-ended cables and terminate the other end themselves. However, excessive force during modifications can damage the genuine terminated end. Handle cables carefully to preserve the integrity of the factory-crimped connection.

4. Handle Retention Features with Care

Handle Retention Features with Care: Crimped contacts and terminals have small yet essential retention features that keep them secured in housings. Mishandling can damage these features, leading to poor retention and electrical failures. Always use proper techniques to insert and remove contacts without bending or breaking these retention features.

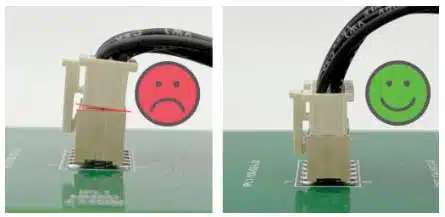

5. Use Proper Demating Techniques

Use Proper Demating Techniques: Pulling on wires to unmate connectors can damage both the wire and the contact system. Instead, use ejector shrouds or demating tools to evenly release connectors without placing stress on individual wires. If a demating tool or feature is not part of the design, then grip the plastic or metal housing while disengaging the latch.

6. Maintain System Compatibility

For optimal results, always use reliable manufacturer components and approved tooling from the same manufacturer. Mixing different brands can introduce inconsistencies in fit, performance, and long-term reliability. Just because a contact system from supplier A appears compatible with a body from supplier B doesn’t guarantee that its features will function as expected.

7. Use the Right Tools for Contact Removal

Improperly removing crimped cables from plastic housings can cause damage, leading to poor retention and future mating issues. Samtec offers specialized tools to safely remove contacts without damaging connectors. Refer to the manufacturing tooling guides, for the recommended equipment.

8. Understand Latch Strength Limitations

Plastic and metal latches are designed to secure mated connectors under normal conditions but are not intended to withstand excessive pull forces. Avoid relying solely on latches to hold connectors in high-stress applications unless otherwise specified.

9. Investigate Issues Thoroughly

If a defect occurs, manufacturers employ various root cause analysis, regression testing, continuous monitoring, and inspection techniques to identify the underlying issues. Consider factors such as tooling calibration, wire specifications, crimp measurement, lubrication, and any modifications made to the tool. Detailed documentation and images can expedite the resolution process.

10. Regularly Maintain and Inspect Tools

Crimp tools require periodic maintenance to function optimally. Ensure that tools are lubricated, calibrated, and inspected regularly to prevent inconsistencies in crimp quality. A well-maintained tool extends the lifespan of your assembly process and minimizes defects.

By adhering to these best practices, you can enhance the quality and durability of your reliable discrete wire assemblies.