The paper “Computer Vision‑Driven Verification of Passive Component Assembly on Space‑Grade PCBs” was presented by Carmen Galán, and Manuel Domínguez, ALTER Technology, Seville, Spain at the 5th PCNS Passive Components Networking Symposium 9-12th September 2025, Seville, Spain as paper No. AI 1.

ABSTRACT

Passive components such as multilayer ceramic capacitors (MLCCs) and thick‑film chip resistors represent more than 70 % of the bill‑of‑materials for modern on‑board electronics. In order to ensure their reliability under extrem conditions affecting the space missions, it is essential to implement a verification programme.

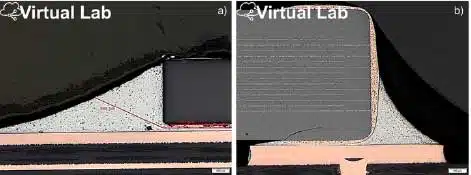

This programme will analyse the solder integrity of assembled components after they have been subjected to thermal and mechanical stress. Herein, the first computer‑vision‑driven workflow concerning the European aerospace sector is presented. This system is based on the automatic analysis of the integrity of passive components and their soldering connections.

A YOLOv8‑based detector trained on 150 000 annotated microsection images identifies ten failure modes—including internal MLCC flex‑cracks and chip‑tilt resistors—with mAP50 of 0.94 and reduces analyst review time.The system has been in continuous production since Q2 2025, generating standardised ESA‑compliant reports and positioning ALTER Technology as a pioneer of AI‑enabled quality assurance for space‑grade passives.

Keywords— passive components; MLCC; chip resistor; computer vision; failure mode analysis; aerospace quality assurance

I. INTRODUCTION

Reliability of space hardware hinges on the integrity of multilayer ceramic capacitors (MLCCs), chip resistors, inductors and other passive components that dominate printed circuit board (PCB) population counts and their soldering connections. A single micro‑crack in an X7R capacitor can compromise mission‑critical power regulation, while tombstoned resistors jeopardise signal integrity.

According to the ECSS standards, to demonstrate the reliability of assembled components, the integrity of both the component and its solder joints have to be analyse after being submitted to mechanical and thermal stress. In this way, the components are sitted for cross-section analysis by optical microscopy, a labour‑intensive process subject to operator bias. Concurrent trends toward 0201/01005 package sizes drive the need for faster, more objective inspection tools. In 2023 the Materials & Processes (M&P) Laboratory at ALTER Technology initiated an artificial‑intelligence programme to automate failure‑mode evaluation of assembled passive component after stress tests, leveraging recent advances in deep convolutional networks.

This paper presents the first computer vision-driven tool developed to assist to the laboratory inspectors in evaluating cross-section samples, harmonising results and optimising inspection time.

II. COMPUTER VISION FRAMEWORK

The workflow (Fig. 1) begins with high‑resolution imaging (0.5 µm pixel size) of resin‑embedded cross‑sectioned assembled components. A proprietary dataset of 150 000 images was curated, with expert metallographers annotating bounding boxes and segmentation masks for ten distinct failure modes. This failure modes were selected based on the anomalies describes in the standards ECSS-Q-ST-70-61C.

Data augmentation—rotation, translation, adaptive histogram equalisation, blur and synthetic noise—mitigated class imbalance and improved robustness against illumination artefacts.

The detection backbone is Ultralytics YOLOv8‑L, initialised with MS‑COCO weights and trained for 400 epochs on dual NVIDIA GPUs using a combined BCE‑CIoU loss. Custom anchor boxes matched the small‑object priors typical of 0201 packages. The tool was trained using anonymises metadata to ensure the independence of the results and to avoid any potential bias of the programme related with manufacturer, assembly technique…. This philosophy aslo guarantees the confidentiality and security of the results.

III. FAILURE MODE CATALOGUE

Table 1 summarises the passive‑component failure modes addressed by the model. Beyond conventional solder‑joint anomalies, the network recognises internal dielectric defects and mechanical damage unique to ceramic bodies. The catalogue was prioritised in consultation with component and process‑assurance (PA) engineers across six European satellites programs.

| Failure mode | Description | Precision | Recall |

|---|---|---|---|

| Flex‑crack (MLCC) | Diagonal crack across inner electrodes caused by board bending. | 0.95 | 0.92 |

| Delamination | Layer separation within MLCC dielectric stack. | 0.94 | 0.90 |

| Blow‑hole | Voids in termination metallisation. | 0.93 | 0.91 |

| Tombstoning | One termination lifted, component stands vertically. | 0.96 | 0.94 |

| Chip tilt | Component seated at >3° angle to PCB surface. | 0.94 | 0.92 |

| Cold solder fillet | Dull or insufficient wetting on termination. | 0.92 | 0.89 |

| Lifted pad | Copper pad detached from PCB under component. | 0.91 | 0.88 |

| Resistor hot‑spot burn | Localised overheating discoloration. | 0.93 | 0.90 |

| Cracked resistor glaze | Surface protective glaze fractured. | 0.92 | 0.87 |

| Void under termination | Solder void >25 % under MLCC termination. | 0.95 | 0.91 |

IV. EXPERIMENTAL RESULTS

The trained model achieved an overall mAP50 of 0.944 and mAP50‑95 of 0.836 on a held‑out validation subset comprising 45 000 images. Failure‑mode‑specific metrics are included in Table 1. Inference throughput is 16 fps (4 k resolution) on a single RTX A6000, enabling real‑time review during microsection polishing. The false‑negative rate decreased below 3 %. A blind verification campaign with ESA PA engineers on 300 production samples confirmed 97 % agreement between AI predictions and expert consensus.

V. DISCUSSION & INDUSTRIAL IMPACT

The proposed workflow extends beyond traditional solder‑joint inspection by providing component‑level insights crucial for derating and reliability modelling. Automated quantification of flex‑crack length, solder void area and chip tilt angle feeds directly into stress‑ strength analyses, enabling earlier rejection or rework of marginal assemblies. The system’s modular architecture supports quick retraining for novel package types—e.g., high‑voltage C0G capacitors—and is now being evaluated for wire‑bond pull‑test segmentation. ALTER Technology is coordinating a pan‑European consortium to establish a shared, anonymised defect atlas, accelerating standardisation and reinforcing Europe’s strategic autonomy in semiconductor packaging.

VI. OUTLOOK FOR PA ENGINEERS

For PA engineers, the most immediate benefit lies in the harmonisation of defect classification. Machine‑generated, timestamped reports embed annotated images and quantitative metrics, reducing subjective disagreements during board acceptance reviews. Future releases will introduce Bayesian confidence estimates, allowing risk‑based escalation paths in accordance with ECSS‑Q‑30‑11A. Integration with IPC‑1782 traceability schemas is underway, paving the path toward fully digital process assurance for passive components.

VII. CONCLUSIONS

By integrating a YOLOv8 computer‑vision detector as part of the verification solder programme for passive components on space‑grade PCBs, the ALTER Technology M&P Laboratory has achieved a transformative leap in quality assurance. This is the first operational AI‑assisted inspection line for passives in the European aerospace supply chain. The approach shortens feedback cycles, increases defect detection fidelity and opens new avenues for predictive reliability modelling.

ACKNOWLEDGMENTS

The authors thank the European Space Agency’s Directorate of Technology, Engineering and Quality for continuous guidance.

REFERENCES

- [1] ECSS‑Q‑ST‑70‑61C, “High‑reliability assembly for surface‑mount and through‑hole connections,” ESA, 2022.

- [2] J. Kim et al., “Flex‑crack propagation in MLCCs during reflow,” Microelectronics Reliability, 2024.

- [3] N. Jegham et al., “Evaluating the evolution of YOLO models,” arXiv:2411.00201, 2024.

- [4] L. García et al., “AI‑based defect detection in ceramic capacitors,” Proceedings of ESTEC Components Day, 2025.