This Würth Elektronik webinar aim to show where the difference between calculation and measurement of PCB heat dissipation comes from, even for relatively simple assemblies.

Without time-consuming thermal simulations, demanding heat dissipation of assemblies cannot solve satisfactorily.

But, to what extent can simple thermal requirements on PCBs be determined with basic mathematics?

How well do the results correlate with real measurements?

Correlation Between Calculation and Practice for Simple Top-to-Bottom PCB Heat Dissipation Using TIM

Abstract

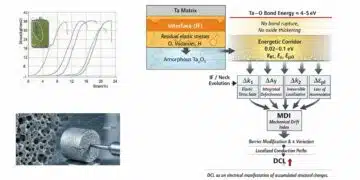

This presentation investigates the correlation between theoretical calculations and practical observations in thermal management of PCBs, focusing on simple top-to-bottom heat dissipation using Thermal Interface Materials (TIM). The study utilizes a specially designed demo board to evaluate discrepancies between calculated thermal resistances and actual measured temperatures.

1. Introduction

Effective thermal management is critical in modern electronics due to increased power densities. This paper aims to bridge the gap between thermal calculations and real-world performance, providing insights into the factors contributing to deviations.

2. Experimental Setup

2.1 PCB Design and Components

A demo board featuring an SMT component with a D2PAK package mounted on the PCB’s bottom side was designed. The setup included thermal vias, TIM, and a heat sink.

2.2 Measurement Tools

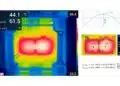

- FLIR thermal camera

- Thermocouples for validation

- Controlled environmental conditions to minimize airflow effects

3. Theoretical Framework

3.1 Thermal Resistance Calculations

- Junction-to-ambient (RθJA) and junction-to-case (RθJC) resistances derived from datasheets.

- Calculation of thermal resistance for vias, TIM, and heat sink using standard formulas.

3.2 Via Array Configuration

An 11×11 via array optimized for effective thermal conduction, with thermal resistance values computed based on copper conductivity and PCB thickness.

4. Practical Observations

4.1 Temperature Measurements

Temperatures were measured under various conditions, including different TIM materials, compression forces, and heat sink attachment methods.

4.2 Deviation Analysis

Observed deviations of up to 20°C between calculated and measured temperatures were systematically analyzed.

5. Discussion

5.1 Sources of Deviation

- Inconsistent contact pressure between the heat sink and PCB.

- Lateral thermal resistance of copper planes.

- Impact of solder paste thermal resistance.

5.2 Mitigation Strategies

- Use of screws instead of cable ties for uniform pressure.

- Optimizing via arrays and PCB copper thickness.

- Selecting appropriate TIM materials based on application requirements.

6. Conclusion

The study highlights critical factors influencing thermal performance beyond theoretical calculations. Accurate modeling requires considering real-world variables like contact quality, material aging, and PCB design intricacies.