This article is based on newsletter blog written by Sotiris Zorbas, MSc Power Εlectronics Εngineer of Frenetic that explore the basic aspects of a custom magnetic design process flow that an engineer should possess before starting a custom design inquiry.

Basic Specs to Start with

In order to make custom magnetic samples and move to production, there are certain topics that needs to be clarified, such as:

- Topology of the Inductor/Transformer operation.

- Input and output voltages and currents of the power topology.

- Frequency range.

- Required insulation for the design.

- Cooling options for the Converter.

- Mass production requirements.

Then it’s time to perform spice simulations, what we look for at the beginning is the following:

Key Specification Parameters

Depending on the topology, the primary inductance (L, or Lp) is the first important spec needed to figure out.

For the Inductor, that would be the measured inductance across the terminals, while for the Transformer the primary inductance with the secondaries open. Measurements of inductance should be performed at least on the operating frequency range of the Magnetic part, as inductances vary with frequency!

For Transformers, the turns ratio n of the primary/secondary is also an indispensable parameter.

Depending on the topology and control options, both L and n need to be calculated. Without these specs, you can go no further. It’s common for uncertainty to surround these parameters, since the designer often needs to dive into equations to find a suitable range of values. Usually, the story is quite simple for Inductors, but not so much for Transformers!

Let’s pick some examples!

First example:

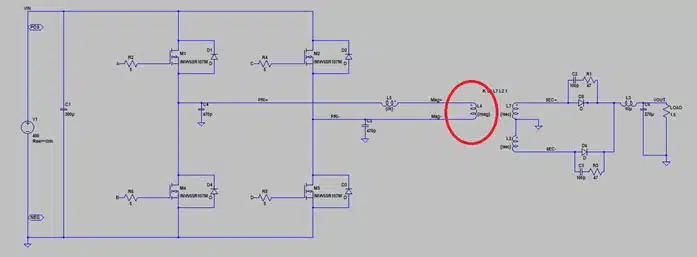

A client has a PSFB custom transformer and specifies 4mH of primary inductance. That much inductance is forcing the design into a high number of turns, thus increasing winding losses.

The question would be: Why does he need 4mH of inductance? Is he choosing to operate the PSFB Converter with peak current mode control scheme? The solution in this case is to double check the minimum inductance needed to safely operate in current mode control in this case and have a chat about it.

Second example: what should be the turns ratio in a PSFB?

With the fair assumption that a maximum effective duty cycle of 70% is selected, given the highest/lowest voltages on the output/input respectively, we can calculate a turn ratio. Now, if the client does not have a clue of the effective duty cycle parameter, then we can ask for more info on his system to double check if this is the case.

Insulation

Do we need functional, basic, or reinforced isolation for the transformer design?

Don’t worry about the details. If that’s a new concept for you, we can propose appropriate insulation to meet certain standards for your product. The point with insulation is not only to pass the standards, but also to ensure the safety of the end-product user.

Cooling and Space

We are building a Magnetic part, let’s assume a Transformer. Typical efficiencies range vary from 98.4% to 99.7%. Although Magnetics are extremely efficient components by nature, there are losses that are then translated into heat, and we need to account for that.

Depending on the power level of the Converter, heat dissipation will result in a temperature rise. The usual specification is to keep temperature below a certain point under worst ambient temperature conditions. To achieve this, we need to cool the Magnetic somehow.

3 options for cooling are:

- Natural convection cooled design.

- Forced air cooling.

- Potting and plate cooling

The Transformer temperature models we have developed will point us in the right direction once a design has been simulated and its power losses calculated. We need to keep in mind that the maximum dimensions of the Magnetic component will heavily influence the design options thus power losses, temperature rise and finally cooling method.

Samples and Production

When a salesperson inquiry about mass production volume and timelines, their intent is clear: ensure feasibility within specified timelines and cost structures that align with both the client’s and Frenetic’s objectives. No mysteries here…

But when our engineers ask you these very questions, why is that? The difference between creating a functional sample meeting specifications and designing a product suitable for large-scale manufacturing becomes apparent. That’s just reality. When we start with mass production as a goal with certain price tags, the designs are going to be different, even at the initial sampling stage.