Source: EEStor news

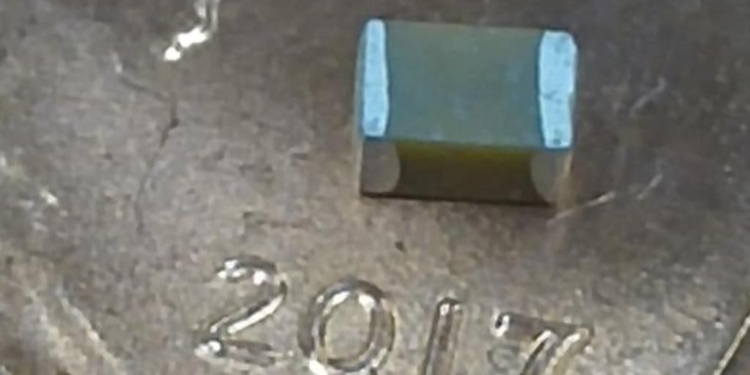

EEStor Reveals Results of Multilayer Ceramic Capacitor Tests. Results show EEStor’s proprietary Composition Modified Barium Titanate (CMBT) powder can be utilized in the Multilayer Ceramic Capacitors (MLCC) process producing dielectrics with a relative dielectric constant of over 30,000, which is significantly higher than equivalent technologies.

Toronto, Ontario – October 23, 2018 – EEStor Corporation a developer of high energy density, solid-state capacitor technology, today announced the results of independent third party production and performance testing of Multilayer Ceramic Capacitors (MLCCs), made with EEStor’s proprietary Composition Modified Barium Titanate (CMBT) powder.

In a first for the MLCC industry, EEStor’s CMBT powder has been used to create densified ceramic layers and Multilayer Ceramic Capacitors using standard Multilayer Ceramic Capacitor processes.

During production tests, EEStor’s CMBT was used to create MLCC devices and densified layers with high relative permittivity, high insulation resistance and low dissipation and predicted long lifespan. The test results demonstrate that EEStor’s high permittivity CMBT powder is not only compatible with standard MLCC manufacturing techniques, it can also be used to create superior performing and long lasting MLCC devices.

Test methods

Densified ceramic layers without electrodes called “K-squares”, as well as a small production lot of size .0805 MLCCs, were manufactured by MRA Laboratories through MRA’s standard MLCC processes, utilizing EEStor produced CMBT powders. Testing to characterize these densified ceramic layers and MLCC capacitors was completed by Intertek, MRA and Radiant Technology.

Results

The latest tests carried out between August and September of 2018 by Radiant, MRA and Intertek, demonstrated that MLCC techniques can produce a lead-free relaxor dielectric material, with a very high relative permittivity of over 30,000, alongside low residual polarization, high insulation resistance and low dissipation.

In addition, Highly Accelerated Life Testing (HALT) predicts a long expected lifespan for the produced MLCCs, with 20 out of 20 units passing HALT tests with an average of 1 tera-ohm resistance after 100 hours at 180˚C.

The EEStor MLCCs meet Electronic Industries Alliance (EIA) RS-198 Standards for X7V and Y5V thermal performance criteria. This demonstrates EEStor’s high permittivity CMBT powder is compatible with standard MLCC manufacturing techniques.

White Paper is available in pdf here.

featured image: EEStor 0805 MLCC on a penny; image credit: EEStor