source: Kemet engineering center tech article

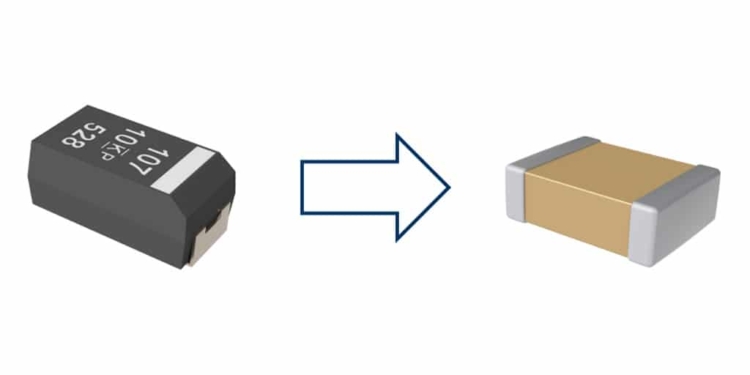

Kemet Engineering Center just released a technical article on tantalum polymer to MLCC guidelines reflecting the current MLCC shortage issues. This is a complementary article to the original EPCI paper on tantalum to MLCC replacement considerations published in April 2018 here. Wilmer Companioni, Friday, May 4th, 2018

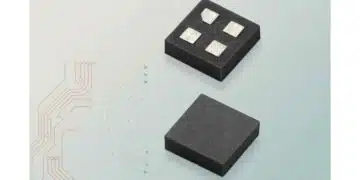

A Primer On KO-CAP

Let’s all get to the same baseline. KO-CAP is KEMET’s tantalum-based polymer electrolytic capacitor. Like any other tantalum capacitor, it is a slug of sintered tantalum powder that has a tantalum pentoxide layer grown on it, with a layer of conductive polymer acting as the cathode. This conductive polymer gives the capacitor much lower ESR than “traditional” tantalum capacitors. That’s all I have to say about that.

MLCC to KO-CAP

I am not delusional, I was (am) an engineer too and selling me on tantalum when I’m looking for MLCCs isn’t exactly the way to my heart. But, as engineers, solving problems is what we do and that means doing things we haven’t previously considered. As with anything else in engineering, making the decision to go to KO-CAP from MLCC is just a matter of managing tradeoffs. There are a slew of things that must be considered when making that decision. The critical design parameters that must be considered when attempting to make the change are; capacitance, voltage, ESR, frequency, leakage current, size, and qualifications. The flow chart below serves as a guide to making that decision when considering each of those critical design parameters. We are going to look at it from the standpoint that you’re trying your best to get as close as possible to the characteristics of your ceramic capacitor.

Capacitance

KO-CAPs tend to have much high capacitance than a similarly sized ceramic capacitor. They don’t come in values smaller than 680nF. So, if your total capacitance is less than that, KO-CAP is not a suitable option. When it comes to capacitance, it is usually a very strong value proposition to replace a bank of MLCCs with one or two KO-CAPs.

Voltage

In KO-CAP, or any tantalum-based capacitor for that matter, the dielectric layer is very thin. A typical value is about 20nm. Having such a thin dielectric gives you a large amount of capacitance, but it also has the effect of limiting your voltage. A “high voltage” KO-CAP would be anything more than 35V. In general, if your operating voltage is more than 50V, KO-CAP is not a suitable option.

ESR

Ceramic capacitors, in a general sense, have lower ESR than an equivalent KO-CAP counterpart. That is not to say that there aren’t some very low ESR KO-CAPs. Some even go as low as 8mΩ, but a typical cutoff of 10mΩ is adequate. If you need ESR less than that, then KO-CAPs may not be a suitable option.

Frequency

What you have to watch out for when considering frequency characteristics of KO-CAP is the self-resonant frequency. You generally want to operate capacitors below this point. It isn’t always the case, but if your switching frequency goes much higher above 1MHz then you should look out for that self-resonant point of a KO-CAP.

Reverse Bias

KO-CAPs are polar devices, as such, they can not take reverse bias voltage. If the capacitor is placed in a location which reverse bias is possible or needs to be tolerated, KO-CAPs are not suitable.

A Replacement Example

Alright, we have our guidelines, so what do we do now? What does this all mean. Let’s take a look at an example using a TI TSP54560B-Q1, that’s a buck for automotive applications.

I am an engineer and I have this circuit designed and everything is great. Until my sourcing person tells me that they can’t find some of the MLCCs I need. After berating them for a little while, I decide it is time to get creative and find a solution. Using the replacement guidelines I come to the conclusions below.

Input Side

C1, C2, C3, and C10 are my input side capacitors. They are 2.2uF 50V 1206 X7Rs. There isn’t a drop-in replacement for the ceramics, but I can take the total 8.8uF capacitance and replace the 4 ceramics with one 10uF 35V KO-CAP. It is more than the original capacitance we need, but it is still within the required range for this regulator. ESR, Leakage, and frequency are not of concern on the input side, as long as the input isn’t direct battery voltage. Our simulation tool, K-SIM, show their side by side comparison.

Yes, I hear your concern, “what’s this going to cost me?” Well, let’s do the math. The total cost of the 4 MLCCs is $4.16. Replacing those 4 with one KO-CAP saves about a bit over a dollar.

Output Side

On the output side we have C6, C7, C9, and C11; 22uF 10V X7R 1206s. In this case we are lucky, there is a drop-in replacement of that in KO-CAP. It is 6.3V but more than the output voltage range. In this case the KO-CAP ESR is higher than the ceramic equivalents, but still within the design spec. The switching frequency of the circuit is 300kHz and the SRF of my replacement is around 1MHz, so I am good there.

Money-wise, we have similar story on the output side. In this case we have an MLCC that is nearly $2! Yeah, I know it is a very expensive cap, but you can’t even get it anyway, so it is a moot point. The KO-CAP replacement is just over a dollar. Saving you a whopping 45%.

Other Capacitors and Considerations

C4, C5, and C8 are other caps that support the functionality of the device. There are suitable candidates for substitution because of both their physical size and capacitance value. Caps of this type are not experiencing quite the same capacity crunch. I didn’t mention leakage current very much because in truth, that is only a concern in systems that have fixed non-rechargeable batteries.

MLCC Substitution Conclusions

Finding a drop-in replacement is doable but it isn’t the same level of value proposition as replacing a bank of capacitors with a much lower quantity of KO-CAPs. Sometime a substitution won’t be feasible, but during times of capacity crunches such as this, finding solutions through other avenues could make you the hero your project deserves.

article, featured image and figures credit: Kemet