Source: electropages news

by Nnamdi Anyadike

Whether it is sensors for autonomous driving or light emitting diodes in smart clothing many industry sectors increasingly rely on lightweight and flexible electronics components. On March 19, manufacturers, users and researchers will meet in Munich to discuss innovations and trends in printed electronics at LOPEC, the three day international exhibition for printed electronics.

Wolfgang Mildner, CEO of the consulting and technology company MSW said, “Printed electronics has evolved into a cross-sectional and key technology.” The key focuses of the industry are on human-machine interactions and 3D-structural electronics and innovative materials. IBM’s Watson IoT Center is working on the combination of printed electronics and artificial intelligence to ensure safety in the workplace. And the Spanish textile technology institute AITEX, as well as the Finnish company Polar, is looking into e-textiles and portable electronics.

Printed electronics in medical diagnostics

Printed electronics including sensors that monitor bodily functions and lab-on-a-chip (known as microfluidics) for a quick test at the bedside are also being used in medical diagnostics. And although printed electronics have already established themselves in many areas of medicine and diagnostics, their potential is still far from exhausted. Consulting firm Mordor Intelligence predicts that printed electronics in this market will grow by almost 25 percent by 2023.

Dr. Kerry Adams, Market Segment Manager at DuPont Advanced Materials, UK said, “Thanks to the rapid development of materials and printing techniques, printed electronics is pioneering the decentralisation of diagnostics and care.” The company is one of the leading manufacturers of customised biomedical materials and is making a major contribution to the advance of printed electronics in healthcare.

The US headquartered Nissha Si-Cal Technologies and its subsidiary GSI Technologies now produce printed electrodes for rapid tests on blood sugar, cholesterol and biomarkers of heart attacks. The company is also active in the growing market for microfluidics using blood or urine.

New printing technologies

In February, Optomec a leading global supplier of production grade additive manufacturing systems for 3D printed electronics showcased its new Aerosol Jet systems for 3D production-grade printed electronics in Monterey, California. The technology offers a means of printing conductors and attaching discrete ICs, passives, LEDs and sensors to 3D and flexes substrates.

Meanwhile, researchers at Purdue University have developed a new fabrication method that will allow future electronics components to be printed like newspapers. Current metal fabrication techniques that are used in the manufacture of cell phones, laptops, tablets, and other electronics make the internal metallic circuits by getting a thin rain of liquid metal drops to pass through a stencil mask in the shape of a circuit, similar to spraying graffiti on walls.

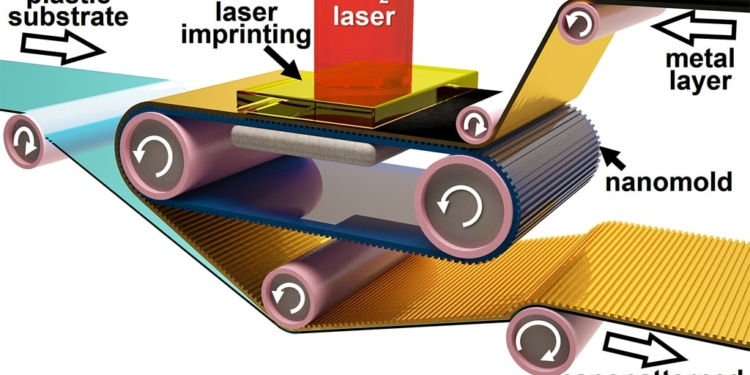

But as Ramses Martinez, assistant professor of industrial engineering and biomedical engineering told the American Chemical Society, “This fabrication technique generates metallic circuits with rough surfaces, causing electronics devices to heat up and drain their batteries faster.” The researchers’ new technique allows for better current flow throughout a metallic circuit. “In the future, the roll-to-roll fabrication of devices using our technique could enable the creation of touch screens covered with nanostructures capable of interacting with light and generating 3-D images, as well as the cost-effective fabrication of more sensitive biosensors,” he said.

featured image: Roll-to-roll laser-induced superplasticity, a new fabrication method, prints metals at the nanoscale needed for making electronic devices ultrafast. (Purdue University image/Ramses Martinez)

Printed electronics finally comes of age for aerospace

Aerospace is another promising end use sector for printed electronics. Dennis Hahn from Airbus told the Web Site, ‘Inside Composites’, that his company has been interested in printed electronics from as far back as 20 years ago. However, the materials then did not yet meet the extremely high safety requirements of aviation. “But a lot has happened since then” he said.

Together with two Fraunhofer Institutes and the consulting and technology company Altran they have developed demonstrators and are providing proof that printed electronics are ready for applications in aviation. “We are now working on the first near-series prototypes, on a display module for the emergency exit and for the toilets in the cabin. We screen print a silver ink onto a polymer carrier, which we then glue onto a honeycomb structure,” said Hahn.

Outlook

Printed electronics is riding high on the rapid evolution of materials and manufacturing processes. Innovative printing techniques and new materials, including magnetic inks and new semiconductor polymers as well as microfluidically produced nano materials, are all playing an enabling role. And this is likely to provide a significant boost to the market in the coming decade. A recent report from IDTechEx Research expects growth in the total market for printed, flexible and organic electronics to grow from $31.7 Billion in 2018 to $77.3 billion in 2029. Strong growth is expected from the printed and flexible sensors segment that in 2018 was worth $3.6 billion.