This article by Dr. V. Azbel, an Independent consultant on tantalum capacitors discusses role of internal stress to reliability of tantalum capacitors.

Abstract

The long-term reliability of tantalum capacitors is often assessed by leakage current (DCL). However, this parameter does not always reflect the true stability of the Ta₂O₅ dielectric film, especially after reformation, when the oxide “heals.”

In this study, we demonstrate that the decisive factor for dielectric stability is the level of internal stress within the anode. Using tantalum foil as a model system, samples with high and low internal stress were compared under identical processing conditions.

Results show that internal stress accelerates oxide degradation under heat, while stress-free anodes retain stable barrier properties. A practical indicator of reliability is proposed: the relative change in yield strength after annealing at 450 °C (Δσ). Low Δσ correlates with structural stability and minimal life-test failures, while higher Δσ corresponds to increased degradation.

1. Introduction

Tantalum capacitors are widely used in aerospace, medical devices, telecommunications, and consumer electronics due to their high volumetric efficiency and excellent frequency characteristics. Further enhancement of their already excellent long-term reliability remains a critical factor, especially in mission-critical applications.

The failure of tantalum capacitors has often been linked to thermal and electrical overstress, as well as impurity-induced degradation of the Ta₂O₅ dielectric. Historically, leakage current (DCL) and accelerated life testing were the primary methods used for reliability assessment. Yet these approaches sometimes failed to predict early-life failures, especially in cases where the oxide film temporarily “healed” after reformation.

Tantalum capacitors rely on the composite system tantalum (Ta) – amorphous Ta₂O₅ film as the core element of their dielectric structure. The stability of this system determines leakage current (DCL) during operation, which is traditionally used as the quality metric. However, the oxide system is prone to degradation due to oxygen gradients between the metal and the film. At elevated temperatures, the Ta–O bond may weaken. Moreover, defects and internal stresses formed during anode processing exacerbate degradation, accelerating diffusion of oxygen and nitrogen into the structure.

For many years, internal stresses were considered a “materials science abstraction.” Recent findings demonstrate that they are, in fact, a key factor in dielectric aging, directly influencing the barrier properties of the Ta₂O₅ film.

2. Industrial Practices and Relevance

Modern tantalum capacitor manufacturing addresses the problem of internal stress through controlled annealing and deoxidation steps. For instance:

- High-temperature annealing (~2000 °C): Reduces dislocation density and relieves rolling-induced stress.

- Low residual oxygen: Achieved via deoxidation treatments, it minimizes the fuel for defect evolution.

- Pre-conditioning heat treatments: Used to identify unstable anodes before assembly.

These practices align with international standards such as MIL-PRF-55365 for solid tantalum capacitors, which emphasize thermal stability as a prerequisite for high-reliability applications.

3. Methods

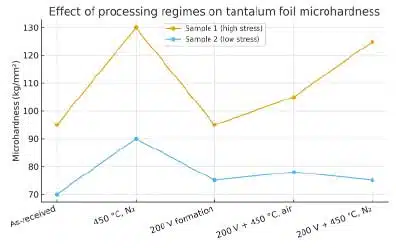

A model system, Ta + Ta₂O₅ film, was constructed using tantalum foil to illustrate the role of internal stress.

Two types of foil were prepared:

- Sample 1 (high stress): after rolling, with high dislocation density and oxygen ≈ 550 ppm.

- Sample 2 (low stress): after annealing at 2000 °C (20 min) and deoxidation at 1000 °C (3 h), oxygen ≈ 150 ppm, recrystallized with low dislocation density.

Both samples underwent identical processing:

- Annealing at 450 °C in nitrogen (20 min)

- Formation at 200 V

- Formation at 200 V + annealing at 450 °C in air (20 min)

- Formation at 200 V + annealing at 450 °C in nitrogen (20 min)

Microhardness was measured after each step (7 measurements per condition) and used as an indirect indicator of structural changes in Ta + Ta₂O₅.

4. Results

- Low-stress samples (Sample 2): retained stable microhardness, indicating that the amorphous oxide film remained defect-free and acted as an effective barrier to gas diffusion.

- High-stress samples (Sample 1): showed increased microhardness after annealing, consistent with structural degradation, penetration of oxygen/nitrogen, and weakening of Ta–O bonds.

These results reveal that internal stress strongly accelerates oxide ageing, while stress-free anodes remain stable under thermal cycling.

5. Discussion

The correlation between structural evolution and dielectric reliability is evident:

- For low-stress foils, thermal treatment does not compromise oxide properties, and leakage currents remain stable.

- For high-stress foils, stress-induced defects promote oxygen diffusion, weakening the dielectric barrier and initiating early degradation.

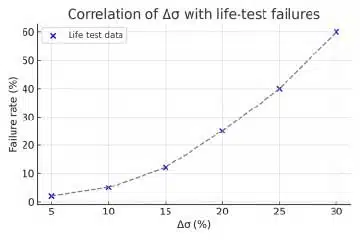

A practical quantitative parameter linking these structural effects to reliability is the relative change in yield strength (Δσ) before and after annealing at 450 °C:

Δσ = |σa – σagn| / σa × 100%

- Small Δσ (<10%) → stable structure, minimal risk of failure.

- Large Δσ (>15–20%) → microstructural instability and higher probability of capacitor failure.

Thus, Δσ provides a clear and quantifiable measure of dielectric reliability.

6. Predictive Value of Δσ

Our findings align with studies in the Journal of Applied Physics, which show that microstructural stability in refractory metals correlates with mechanical property evolution. Measuring Δσ after a 450 °C annealing cycle serves as an early indicator:

- Δσ < 10%: correlates with stable DCL and minimal life-test failures.

- Δσ > 15–20%: indicates high risk of early degradation.

This mechanical approach complements traditional electrical screening, offering manufacturers an early warning system for reliability issues.

7. Practical Implications

- Design for Reliability: Selecting low-stress, purified tantalum foils substantially increases capacitor lifespan.

- Screening and Quality Control: Δσ measurement or microhardness evolution testing provides a non-destructive method to identify weak anodes before assembly.

- Thermal Management in Applications: Minimizing exposure to high operational temperatures reduces the likelihood of stress-driven degradation.

8. Future Work

Further studies may explore:

- Real-time monitoring of stress relaxation during capacitor operation.

- Development of predictive models linking processing, microstructure, and DCL evolution.

- Integration of Δσ criteria into industry reliability standards to better forecast long-term performance.

By combining mechanical and electrical assessments, the industry can achieve a more predictive and robust framework for tantalum capacitor reliability.

9. Conclusions

This study demonstrates that leakage current (DCL) alone is not a reliable measure of dielectric stability, especially after reformation, when the oxide film may “heal” and mask underlying degradation. Instead:

- Heat treatment at 450 °C can serve as a stress test: if the film remains unchanged, the anode is structurally stable; if hardness or Δσ increases, degradation is initiated.

- Internal stress is the decisive factor: high stress accelerates oxide ageing, while low stress enhances the protective properties of the Ta₂O₅ film.

- Δσ provides a practical and quantifiable indicator of reliability, showing clear correlation with life-test failures.

- Heat treatment improves reliability only for stress-free anodes; in stressed anodes, it accelerates ageing.

Thus, the internal stress state of the anode determines whether the Ta₂O₅ dielectric remains a reliable barrier under thermal and electrical loads, making it the key predictor of tantalum capacitor reliability.