Researchers from Brno University of Technology; Czech Republic, Tarragona University; Spain and Hokkaido University; Japan proposed novel 3D nanostructured electrodes for capacitors based on porous-anodic-alumina-templated Ta-Nb-alloy/oxide coatings via the magnetron sputtering/anodizing.

Abstract

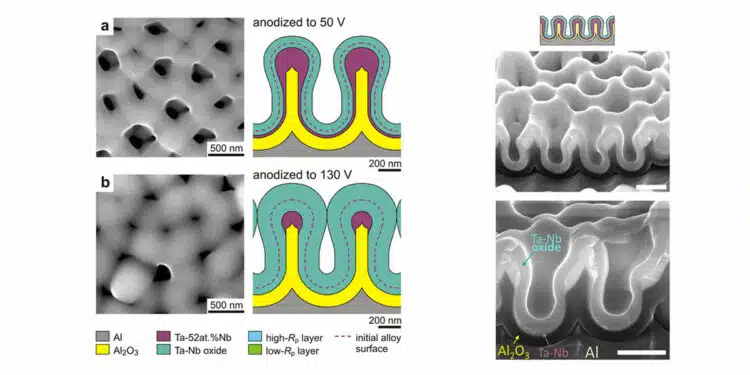

The Ta-52at.%Nb thin alloy films were magnetron sputter-deposited over a low-aspect ratio nanoporous anodic-alumina template formed in 0.05 M tartaric acid solution at 250V and modified by the pore-widening technique to enlarge the pores up to ~500 nm. The alloy coated the pores evenly, thus forming a 3D continuous conducting nanofilm on the template.

Partially anodizing the templated alloy in a borate buffer solution of pH 7.5 generated a compact amorphous mixed-oxide anodic film thickening proportionally to the applied voltage. It was revealed that the oxide on the Ta-52at.%Nb alloy grows with a slower migration of Ta5+ ions relative to Nb5+ ions, resulting in mixing Ta2O5 and Nb2O5 in the film depth and forming a few-nm-thick Nb2O5 outmost layer.

The unique migration of Ta4+, Ta3+, Nb4+, and Nb3+ ions is assumed accountable for forming corresponding suboxides in the 3D anodic film in contrast to a flat Ta-52at.%Nb alloy film used as a reference. The 3D anodic films behave as an n-type semiconductor with a low donor density Nd = ~2×1018 cm−3, appropriate for dielectric applications. An unusual two-layered structure with a sharp electrical interface revealed in the 3D oxide films anodized to 30–130 V, comprising a low resistivity layer superimposed on the high-resistivity layer, is explained by an immobile negative space charge in the outer film part.

The air-annealing at moderate temperatures releases the space charge and transforms the two layers into a high-resistivity single layer having substantially improved dielectric properties and thermostable (up to 250 °C) capacitance of 1.2 uF cm−2 achieved for the film anodized to practical 50 V. The 3D films having up to 4.5 times enlarged effective surface area can be utilized as novel metal/oxide nanostructured electrodes for electrolytic microcapacitors suitable for classical electronic circuits and energy-storage applications.

Introduction and Scope of the Research

Among the various engineered nanostructured materials, 3D nanostructures have become most appropriate for constructing high-performance nano- and microdevices. They seem indispensable for designing electrodes for electrochemical energy conversion and storage devices, including various types of capacitors, which ideally should combine high energy storage and power density.

Electrolytic capacitors are particularly suitable in electronic circuits for passing or bypassing signals, noise filtering, or decoupling. Besides, because of their potential for a large specific volumetric capacitance, electrolytic capacitors can store large amounts of energy, substantially overperforming electrostatic capacitors in energy-storage applications and supercapacitors in dealing with current fluctuations. Tantalum and niobium capacitors with its Ta2O5 respcetively Nb2O5 dielectric layers have been proved as one of the most reliable and high energy density capacitor technologies.

In pursuit of energy storage devices and systems smaller and lighter, the development of 3D nanostructured electrolytic capacitors may contribute substantially to the future high-yield production of large-value electrolytic microcapacitors suitable for on-chip integration. It should be noted that the challenge cannot be met with the ALD approach because it is not appropriate for depositing metal layers and any layers thicker than a few nanometers.

In the present work, we have developed an alternative, ALD-unemploying, facile, and highly reproducible technology for 3D nanostructured electrodes for electrolytic microcapacitors that combines the formation of relatively large-nanopore PAA templates with the DC magnetron sputter-deposition of metal or metal-alloy layers and subsequent partial anodizing of the deposit for forming continuous anodic-oxide layers of various thicknesses to serve as the capacitor dielectric.

To this end, we adopted a set of technological, electrical, and electrolytic conditions for forming a low-aspect-ratio PAA template in which the pore population density, pore size, and pore depth were balanced to achieve a substantial rise in the open film surface. Recently, niobium capacitors were developed and became an alternative and competing technology for tantalum electrolytic capacitors.

In the present work, we mixed tantalum with niobium to create a solid solution with approximately equal concentrations of the components, striving to improve the properties of individual metal oxides toward better-quality dielectrics based on previous reports justifying the advantages of such mixing.

For the first time, the Ta-Nb alloy was magnetron-sputter deposited over the PAA template in such a way that it conformally coated the pores, leaving the pore necks unblocked by the deposit and allowing anodizing voltages up to 130 V. The PAA-templated, anodized, and annealed alloy layers were examined by scanning electron microscopy (SEM), X-ray photoelectron spectroscopy (XPS), X-ray diffraction (XRD), electrochemical impedance spectroscopy (EIS), and Mott-Schottky analysis to gain an insight into the formation-structure-property relationship of these unique 3D nanostructures and assess their applicability as the electrodes for electrolytic microcapacitors.

Summary and Conclusions

- The Ta-52at.%Nb alloy coatings were magnetron sputter-deposited and partially anodized over a PAA template with 500 nm pores to form high-quality continuous 3D alloy/oxide nanofilms of up to 4.5 times enlarged surface area.

- The anodic films grow by migration of cations and anions, with slower migration of Ta5+ ions relative to Nb5+ ions, creating mixed oxides in the film depth. The unusual migration of Ta4+, Ta3+, Nb4+, and Nb3+ ions forms several suboxides in the 3D anodic-oxide nanofilm.

- The anodic films behave as an n-type semiconductor with low donor densities Nd = ~2×1018 cm−3, appropriate for dielectric applications.

- The two-layered structure revealed for the 3D nanofilms anodized above 30 V transforms into a single high-resistivity (~100 MΩ cm2 nm−1) layer after air annealing at temperatures over 200 °C due to releasing the negative space charge from the outer film part.

- The capacitance of the 3D oxide nanofilm formed by anodizing to practical 50 V is 1.2 uF cm−2 and independent of annealing temperature, while the anodic oxide becomes increasingly dielectric with rising annealing temperature above 200 °C.

- The coatings developed here may be utilized as novel 3D nanostructured electrodes/dielectrics for electrolytic microcapacitors suitable for traditional electronic circuits and energy-storage applications. Gas-sensing, superhydrophobic, or biomedical effects may also arise in these 3D nanofilms, similar to some previously reported self-organized anodic oxides on valve metals.

Read the complete article under link here:

A. Mozalev, M. Bendova, F. Gispert-Guirado, et al., Porous anodic-alumina-templated Ta-Nb-alloy/oxide coatings via the magnetron-sputtering/anodizing as novel 3D nanostructured electrodes for energy-storage applications, Surface & Coatings Technology (2023), https://doi.org/10.1016/j.surfcoat.2024.131042