source: Skeleton article

The temperature in which an ultracapacitor or a battery is used has a big influence on how long its charge lasts. Many of us living in cold climates are familiar with starting problems with our car engines when the temperature plummets below -15°C. Especially older batteries have problems operating at colder temperatures, and at times, that results in having to call for a taxi. If you are totally out of luck, it’s cold enough that your phone’s battery is also handling the cold poorly and refuses to cooperate, at which point trampling through the snow to the nearest bus station is your only option if you want to get to work.

It’s very important to be aware of the factors that influence the operational capabilities of the energy storage devices that power the car, truck, bus, or train you are operating. Let’s look at three different temperature ranges you need to be aware when choosing the optimal solution for your application:

Operating temperature is, as the term suggests, defined as the temperatures at which a device operates. The problem with that definition is that often the operating temperature given by a manufacturer of an energy storage device differs from its actual capabilities. While a device might technically work between the given minimum and maximum operating temperatures, it’s efficiency may be greatly reduced at the low and high end of the operating temperature range.

Ambient temperature is used to refer to the temperature of the surrounding air of the application where an energy storage device is used. A high ambient temperature becomes in issue for example for hybrid buses, because batteries used in them overheat in countries with tropical climates.

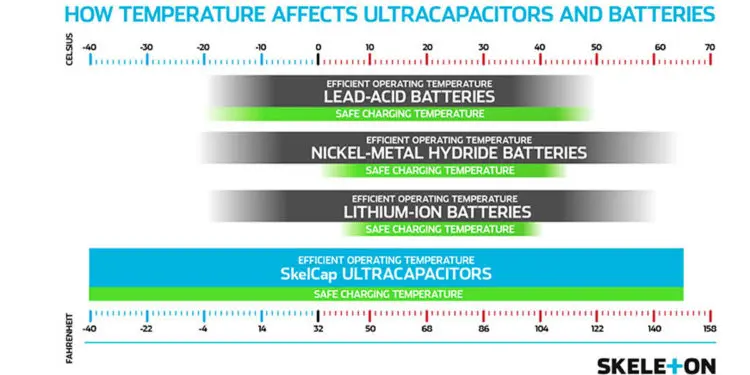

Charging temperature refers to the allowed charging temperatures of devices. Generally all battery technologies have far stricter charging temperature ranges compared to their operating temperature range. Ultracapacitors, on the other hand, can be charged across their operating temperature range, once again giving them a significant advantage over batteries in both cold and warm temperatures.

All three vary heavily depending on the energy storage technology, but ultracapacitors have an edge over batteries regardless of the battery technology used, and they are far more suitable to applications that require efficiency in temperatures that are less than optimal.

Temperature-sensitivity in batteries and ultracapacitors

Lead-acid, nickel-metal hydride, and lithium-ion batteries all operate poorly in cold temperatures. Their efficiency drops, they can not be charged in temperatures below freezing, and they are also unable to operate in some applications in hot climates due to overheating.

Ultracapacitors, or supercapacitors, on the other hand, excel in both cold and warm climates. SkelCap ultracapacitors operate with extremely high efficiency at temperatures ranging from -40°C to +65°C, far beyond the capabilities of any battery technology at both ends of the scale.

Temperature sensitive applications in transportation

The hybrid buses already mentioned above are an important step towards a cleaner public transportation. Until now, hybrid buses have been unable to operate in hot climates, but Skeleton’s SkelCap series ultracapacitors are the basis for Skeleton’s industrial modules that are able to operate in ambient temperatures as high as 45°C, making it possible for hybrid buses to be used all around the world.

Trucking is another industry where the ambient temperature of the operating environment is a cause for worry, especially in northern climates. Old or drained batteries are the leading cause for engine starting problems for trucks. Low temperature is not always the cause for the problem, but often old batteries drain in temperatures far below freezing, which means they are unable to start the engine.

Skeleton’s SkelStart Engine Start Module is a solution for truckers battling with their truck’s batteries. SkelStart is able to function at temperatures as low as -40°C. It can start any truck engine and, in the process, prolong lifetime for the truck’s batteries. Starting the engine is the most demanding task for batteries, but after the SkelStart ESM is installed, the batteries only have to power lights, air conditioning, the lift gate, and hotel loads.