source: TTI Market Eye article

Wearables have moved beyond smart watches, fitness trackers and monitors that can measure human physiology. Wearable electronics can now merge seamlessly into ordinary clothing, becoming an organic part of what we wear. This new class of wearable electronics is being designed to meet innovative applications in the military, public safety, healthcare, sports and consumer fitness.

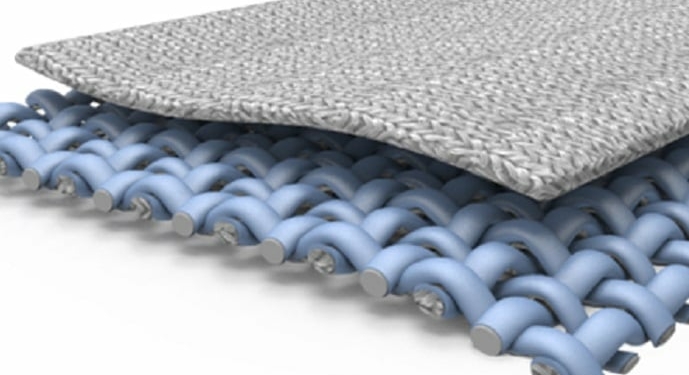

Integrating electronics directly on or into textile substrates involves two major technologies: printing using conductive ink-based solutions and/or embroidering circuits and components directly onto textile substrates via conductive threads.

Let’s look at developments in both types.

Additive printing processes permits the creation of functional electronic components and circuitries. While conductive inks traditionally are used for printing on films and papers, by changing the viscosity of a conductive ink it becomes possible to print on different substrates including textiles. In general, the circuits are made using conventional inkjet printing techniques. The resulting printed circuits are stretchable, comfortable to wear, and can survive numerous cycles in a typical washing machine.

As an example, consider that U.S. team’s parkas made for the opening ceremony of the Winter Olympics in Pyeongchang, where the average temperature in February is about 20 degrees but is widely expected to drop down to single digits this year, employs stretchable conductive carbon and silver ink electrodes printed on the apparel as a hidden heating component. The flexible ink conducts heat and is bonded to the inside of the Ralph Lauren-designed jackets in the shape of an American flag. The heat is controlled by a slim battery pack and can be adjusted to a high or a low setting with up to five hours of heating available at the highest setting and up to 11 hours at the lowest setting.

Blending Electronics with Textiles

For over a decade, textile circuits have been realized by embroidering conductive yarns onto fabric. Unlike metal wires most conductive fibers are so flexible they do not crack or snap if repeatedly bent. This means they can be fed into a loom or embroidered directly onto cloth that can be worn and washed as normal. So-called “Smart Textiles” for military use improve the performance of soldiers by offering them more mobility and fast connectivity. These textiles also safeguard military personnel from visual and infrared light. What is more, integration of smart textiles in military clothing enables a control center to monitor the location, physiological condition or other vital information of the soldier on the ground. The global market for Smart Textiles for the military is expected to grow at a CAGR of around 11% through 2021, according to the research firm Market Research Future.

Percentage of e-textile players using each material type (Image Source: E-Textiles 2017-2027, IDTechEx Research

Printed and Embroidered Passives Components

It is now possible to fabricate simple circuits embedded with several kinds of passive components (e.g., resistors, capacitors and inductors). In a research paper entitled “Printed and Embroidered Electronic Passive Components” presented at the 1st PCNS Passive Components Networking Days, (12-15th Sept. 2017, Brno, Czech Republic), author Tomas Blecha of the Department of Technologies and Measurement, Faculty of Electrical Engineering, University of West Bohemia in Pilsen, Czech Republic and his colleagues from the school’s Faculty of Electrical Engineering investigated and compared the electrical parameters of printed and embroidered planar passive electronic components (the full text is available from the European Passive Components Institute here or from PCNS2017 Proceedings, pgs.80-86). The authors studied different types of inductors and capacitors including meander inductors and square-shaped spiral and Interdigital capacitors (printed on PET foil, embroidered on a textile substrate and embroidered on the textile substrate with one conductive thread).

Printed electronic components were created with silver paste on flexible foil using screen printing technology. Planar components also were created by an embroidery machine. A hybrid thread was used consisting of polyester fibers that were spun with 8 brass wires. The thread consisted of 69% brass and 31% polyester and its electrical resistance was reported to be 7.7 Ω/m.

A Bright Future

Increasing expansion of the Internet of Things is driving demand for printed and embroidered electronics on fabrics. IDTechEx estimates that the total market for printed electronics and flexible printed electronics was worth some USD 7.6 billion in 2017 and will exceed USD 46 billion in 2027. Similarly, the research firm Markets and Markets values the printed electronics market at USD 3.13 billion in 2015 and expects it to reach USD 12.10 billion by 2022, with at a CAGR of 22.38% between 2016 and 2022.

by Murray Slovick

featured image source: power to the people – new material developed by physicists in South Korea generates electricity as it moves,by Sang-Woo Kim