TDK Corporation announced the development and mass production of the MMZ1608-HE series of high-reliability chip beads for automotive use, compatible with high-durability solder in 150 ℃ environments.

This series marks the industry’s first* high-reliability chip bead specifically designed for automotive applications associated with engine control modules (ECM), anti-lock brake systems (ABS), electric power steering (EPS), electric and hybrid electric vehicles (EV/EHV), inverters and LED headlights.

In high-temperature automotive environments, such as engine compartments, high-durability solder is increasingly used to prevent solder cracks in the bonds between chip components and the mounting substrate. Since high-durability solders do not stretch easily and impart higher stress compared with conventional solders, they place a large load on chip components and do not meet the reliability requirements of existing chip beads. With improvements to the terminal electrode material and plating process, the MMZ1608-HE series improves the bonding strength between the terminal electrode and plating, making it ideal for use with high-durability solder in 150 ℃ environments.

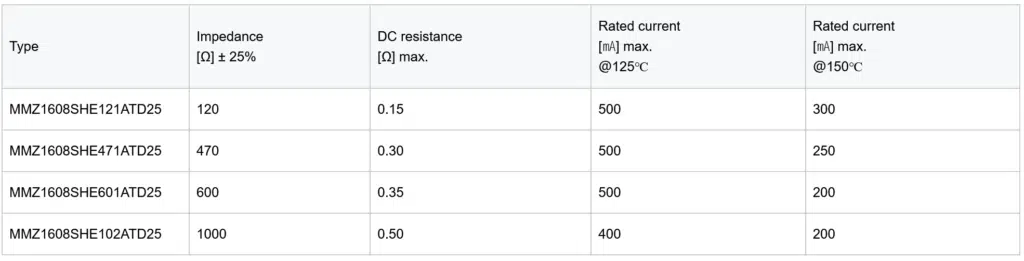

The four products in the series have a rated current max ranging from 200 to 300 at 150 ℃, DC resistance max between 0.15 to 0.5, and impedance from 120-1000, respectively.

TDK will continue to expand its lineup of compact sizes and various impedances to support a wide range of automotive specifications and designs.

* Source: TDK, as of September 2021

Main applications

- Automotive electrical control chips on which high-durability solder is expected to be used, including ECM, ABS, EPS, EV-EHV, inverters and LED headlights

Main features and benefits

- Compatible with high durability soldering in 150 ℃ environments