Attention now turns to exposures, with examples of thermal, mechanical and environmental exposures.

Temperature Life

Temperature life, or heat aging, exposures drive diffusion controlled reactions which include corrosion and stress relaxation. Our discussion begins with stress relaxation with corrosion to be discussed in a later section. The significance of stress relaxation is that it results in a decrease in contact force. As noted in Section 2.2.1.5 Contact Normal Force Parameters, Equation 2.3, repeated here for convenience,

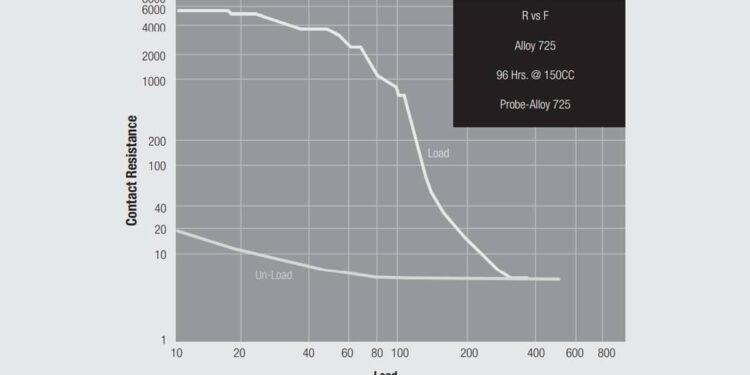

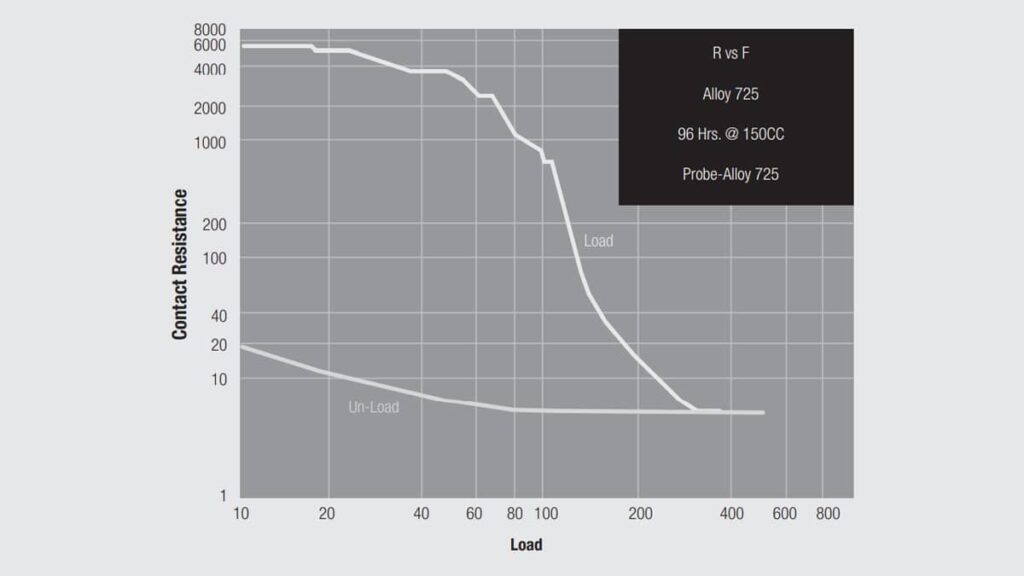

where F is the contact force in a cantilever beam, σ is the stress in the beam and w, t and l are the width, thickness and length of the cantilever beam respectively. So the contact force decreases as stress relaxation reduces the stress in the beam. Recall that, according to Equation 2.10, the contact interface resistance depends inversely on the contact normal force, F, which creates the contact interface area. Consider now Figure 2.102 which shows the contact interface resistance as a function of contact force for both loading and unloading. The loading curve is different from that shown in the main text because it is for a clean metal surface while Figure 2.115 is for a film covered surface, copper alloy 725, a copper-nickel-tin alloy. The initial high resistance region is where film effects are present and the resistance then drops rapidly as the films are disrupted at increased contact force.

It is the unloading curve that is of interest in this discussion. Note that the resistance does not change during the initial stages of unloading. This is because the contact area was created at the maximum normal force and is maintained as the force decreases until elastic recovery forces come into play and the contact area does begin to decrease. Generally the contact force reductions due to stress relaxation are of the order of those in the flat section of the unloading curve. Therefore, stress relaxation does not impact the contact resistance directly. Instead, the effect of contact normal force reduction due to stress relaxation comes into play with respect to contact interface resistance in that the mechanical stability of the contact interface is reduced making the interface more susceptible to mechanical disturbance. If the contact interface is disturbed, that is, moves to a new location, the newly created contact interface will be determined by the stress relaxed contact force and, therefore, will be lower than the original contact interface. It is this two-step process, force reduction followed by disturbance that causes the contact resistance to increase as a result of stress relaxation. This is why temperature life is generally a conditioning rather than an exposure.

As noted in Chapter II/2.5.3 Generic Test Plan, however, there is an additional long term effect of stress relaxation in that the loss in contact force is permanent because the contact beams takes a permanent set due to the kinetics of stress relaxation. This means that all subsequent mating of the connector will have a lower deflection and, therefore, a lower contact force than the original connector prior to temperature life conditioning.

When temperature life is used to drive stress relaxation, the temperature and duration of the conditioning is based primarily on the application temperature and life requirements. For example, say an application has an intended life of 5 years (60 months) at an application temperature of 55 °C. Using the doubling every 10 °C rule of thumb, that time/temperature profile can be realized in 2 months at 105 °C (32 x for ΔT of 50 °C and 2 months time). It is important to keep in mind, however, that increases in temperature may bring different degradation mechanisms into play when making such extrapolations. For a twin beam contact the cited acceleration factor may be appropriate, but for a single beam contact latched into a housing, polymer creep may be excessive at the elevated temperature.