Vishay Intertechnology releases high current, THT through-hole edge-wound inductor IHDM series capable of continuous operation up to 180°C.

The edge-wound technology brings high-current capability and inductance stability at high temperature range for applications current up to 128A DC.

Featuring a powdered iron alloy core technology, Vishay IHDM edge-wound, through-hole inductors provide soft saturation up to 456 A over a demanding operating temperature range from -40 °C to +180 °C.

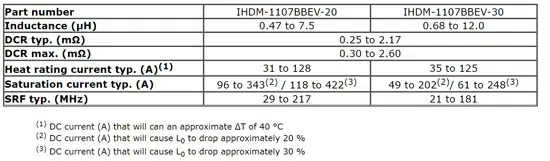

Vishay Intertechnology, Inc. introduced two new IHDM edge-wound, through-hole inductors in the 1107 case for commercial applications with soft saturation current to 422 A. Featuring a powdered iron alloy core technology, the Vishay Custom Magnetics IHDM-1107BBEV-20 and IHDM-1107BBEV-30 provide stable inductance and saturation over a demanding operating temperature range from -55 °C to +180 °C with low power losses and excellent heat dissipation.

The edge-wound coil provides low DCR down to 0.25 mΩ, which minimizes losses and improves rated current performance for increased efficiency. Compared to competing ferrite-based solutions, the IHDM-1107BBEV-20 and IHDM-1107BBEV-30 offer 30 % higher rated current and 30 % higher soft saturation current levels that are stable at continuous operating temperatures to +180 °C. The inductors’ soft saturation provides a predictable inductance decrease with increasing current, independent of temperature.

With an operating voltage up to 350 V, the devices are ideal for DC/DC converters, inverters, differential mode chokes, and filters for motor and switching noise suppression in high current, high temperature applications, including industrial, medical, and military systems. The inductors are available with a selection of two core materials for optimized performance depending on the application. Standard terminals for the IHDM-1107BBEV-20 and IHDM-1107BBEV-30 are stripped and tinned for through-hole mounting. Vishay can customize the devices’ performance — including inductance, DCR, rated current, and voltage rating — upon request. Customizable mounting options include bare copper, surface-mount, and press fit. To reduce the risk of whisker growth, the inductors feature a hot-dipped tin plating. The devices are RoHS-compliant, halogen-free, and Vishay Green.

Features

- High temperature operation, up to 180 °C continuous with no aging

- Low DCR to minimize losses and reduce temperature rise

- Powdered iron alloy core technology provides stable inductance and saturation over operating temperature with satisfactory core losses

- Soft saturation gives predictable inductance decrease with increasing DC current independent of temperature

- Series includes multiple powdered iron core materials for optimized performance in circuit application

- Standard terminal is stripped and tinned for through-hole mounting but other terminal configurations such as bare copper, SMD, and press fit pin are available upon request

- Hot dipped Sn plating provides low risk of whisker growth

- Custom options for inductance, current rating, DCR, mounting style and voltage rating are available

Applications

- High current and high temperature applications

- DC/DC converters

- High current differential mode chokes

- Inverters