With increasing use of electronic modules in under-the-hood applications in the automotive industry, X8* type ceramic dielectrics for up to 150C operating temperature are becoming more and more popular. But, do you know what is the difference between X8G, X8L and X8R ceramic capacitor dielectrics?

There are half-a-dozen ceramic capacitor dielectrics in regular use today: the ultra-stable Class 1 types P90 (porcelain), NPO (COG) and U2J (N2200), and less stable Class II types X7R, X5R and Y5V.

With increasing use of electronic modules in under-the-hood applications in the automotive industry, X8* type ceramic dielectrics are also becoming more and more popular.

X8G, X8L and X8R are all high temperature ceramic dielectrics for use in demanding applications up to +150°C, and all have a lower operating temperature limit of -55°C. This is what the “X” and the “8” signify. The third character represents the capacitance change over this temperature range. The table below shows this capacitance change.

| Ceramic Type | Rated Temperature Range | Maximum Capacitance Change Over Temperature Range |

|---|---|---|

| X8G | -55°C – +150°C | ±30ppm/°C |

| X8L | -55°C – +150°C | ±500ppm/°C |

| X8R | -55°C – +150°C | +15% |

This means that X8L and X8R types are Class II dielectrics, while the rarer X8G type is an ultra stable Class I dielectric. Of course, X8G capacitor dielectric class has a lower permitivity and thus lower Capacitance/CV. That may sound strange … or a good marketing to move attention from less stable class II materials to class I with better stability and performance at high temperature 150C applications.

Major brands such as AVX, KEMET, Knowles, Murata, TDK and Vishay all produce X8L/X8R dielectrics, but only few have X8G types (but of course they have class I capacitors available)

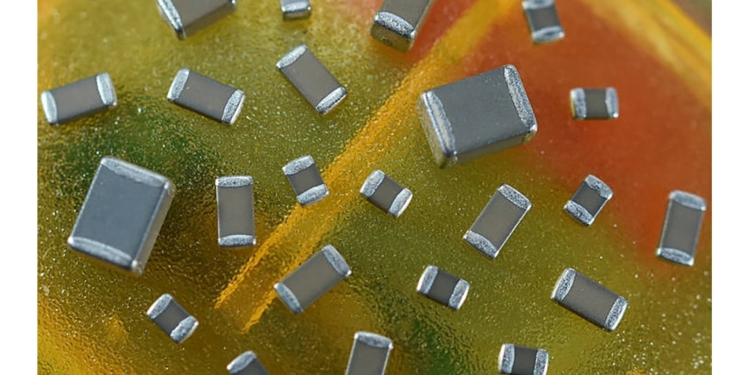

featured image credit: Knowles