This article based on Knowles Precision Devices blog explores role of capacitor technologies in power systems of electric vehicles.

The electrical power systems in most modern technologies, like electric vehicles (EVs), are complex.

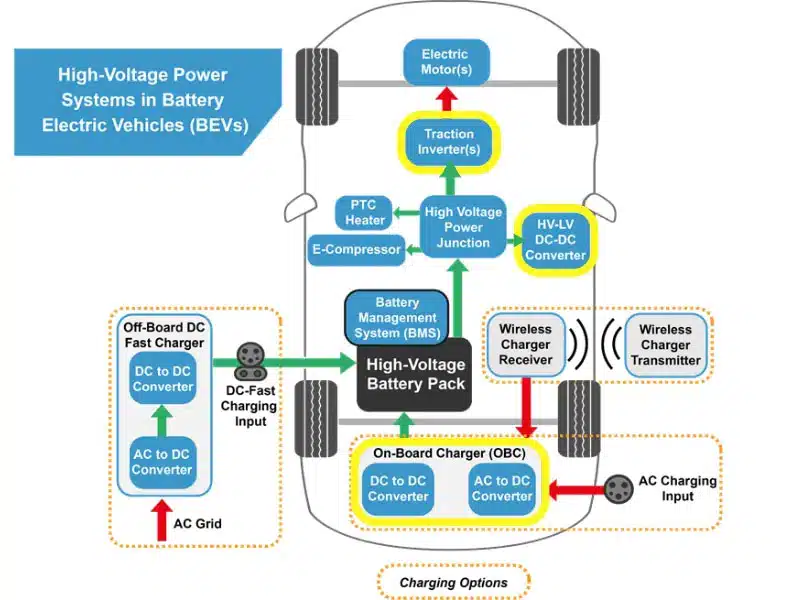

In EVs specifically, power systems are responsible for performing many tasks such as converting AC to DC and DC to AC as well as managing changing power levels in DC/DC conversion.

When performing these tasks, manipulating AC voltages and removing noise from DC voltage requires passive components such as capacitors, to perform many “jobs” inside the power system.

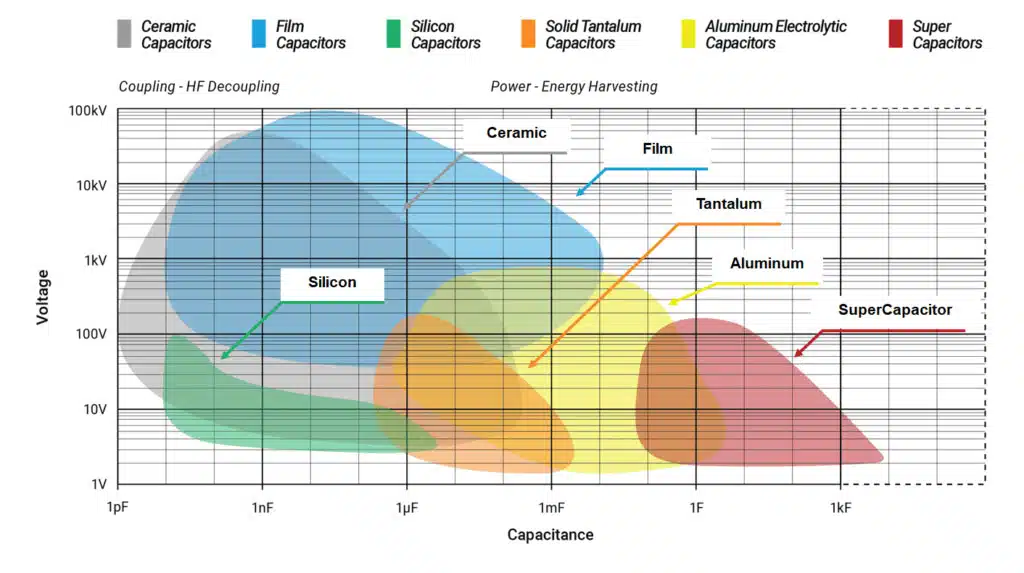

But no single capacitor type can perform all these jobs since each one has different requirements for voltage, size, temperature, and reliability. Therefore, a variety of capacitor technologies, such as ceramic capacitors, film capacitors, tantalum capacitors, aluminum capacitors or supercapacitors are required to meet all these needs.

As a starting point to understanding what technology to use, let’s look at the graph in Figure 1. to see the capacitance and voltage ranges covered by each capacitor type In general, you can expect to see the following capacitance ranges:

Key Functional Components in Radar Systems

We can learn a lot about radar systems by looking at the functional components and what specific tasks they perform. In the diagram below, we treat each function as a separate block, even though these functions can be combined or divided across several circuits.

- Multilayer ceramic capacitors (MLCCs) from under a picofarad to hundreds of microfarads

- Film capacitors from under a nanofarad to tens of millifarads

- Aluminum and Tantalum Capacitors from under a microfarad to several farads

As you can see in Figure 1., each technology’s range overlaps with the other, which means you need to truly understand the specific application and its voltage, size, temperature, and reliability requirements before you can select the best option. Let’s now look at some of the common applications where capacitors are required inside the EV, the different jobs capacitors must take on, and the capacitor technologies commonly used for those jobs.

The Many Roles Capacitors Play in EV Power Systems

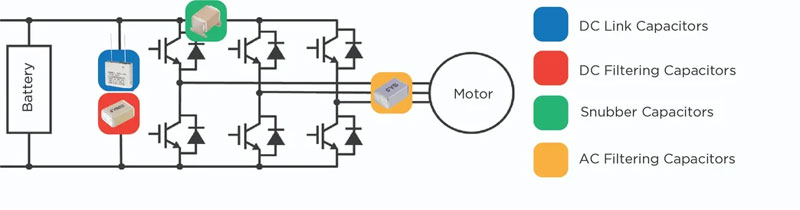

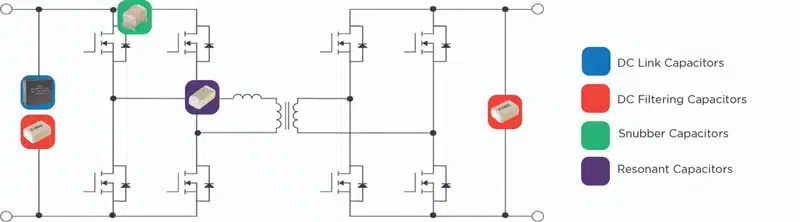

Power systems within EVs must reliably handle large amounts of fluctuating power. While Figure 2 shows all the different functional blocks in an EV power system, we will focus specifically on the roles capacitors play in the following functions:

- Traction inverter (DC to AC)

- Onboard charger (AC to DC)

- DC/DC converter

The major capacitor roles here include the following:

- Snubber Capacitors – Voltage suppression is important to protect circuits from large voltage spikes. Snubber capacitors connect to the high-current switching node to protect electronics from voltage spikes.

- X & Y Safety Capacitors – Safety capacitors mitigate the effects of transient voltages and interference in electrical and electronic circuits, especially in high-voltage applications. There are two classes of capacitors, Class-X and Class-Y, that are both used to minimize EMI in different applications.

- Bypass Capacitors – All electronics depend on clean power, and bypass capacitors are crucial for ensuring devices safely meet their power specifications. These capacitors act as filters, bypassing high-frequency noise.

- Decoupling Capacitors – In power supplies, decoupling capacitors are placed near sensitive components to suppress voltage fluctuations or noise on power supply lines.

- DC-Link Capacitors – In EV applications, DC-link capacitors help offset the effects of inductance in inverters. They also serve as filters that protect EV subsystems from voltage spikes, surges and EMI.

- DC-Link Supporting Filters – Smoothing ripples, storing energy and suppressing surges are critical functions of DC-link supporting filters.

- Flying Capacitors – EVs needs lightweight, compact components. Flying capacitors can balance out voltage and extend the longevity of components.

Traction Inverter

The function of an inverter is to convert DC power to AC. This function is commonly required in the traction inverter in an EV where battery DC is converted to AC for the motor.

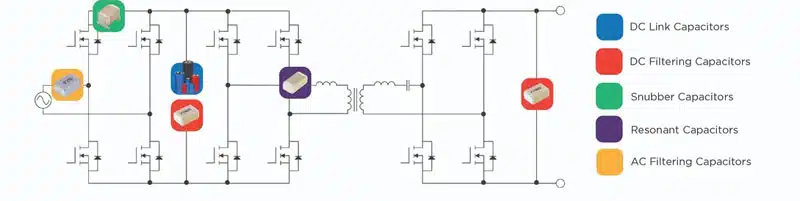

On-Board Charger

An on-board charger takes AC power and converts it to DC to charge the battery.

DC/DC Converter

The DC/DC converter takes the high-voltage battery power and converts it to a lower voltage.

So now you’re probably wondering, of the different capacitor technologies, which one is the best option for each of these jobs?

As mentioned, the type of capacitor technology you will need depends on the specific voltage, size, temperature, and reliability requirements of the application, but there are some overall trends we are seeing:

- Film, Aluminum and MLCC are typically used for DC link capacitors

- Film, Aluminum, Tantalum and MLCCs are typically used for filtering capacitors

- Film and MLCCs are typically used for resonant capacitors

- Film and MLCCs are typically used for snubber capacitors