This article based on Knowles Precision Devices blog discusses in brief role of ceramic capacitors supporting DC link filters.

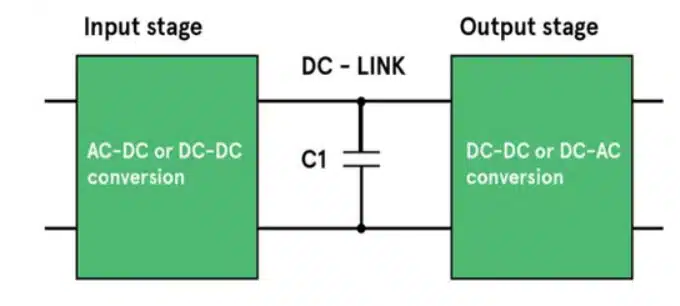

In power electronics, the DC link refers to the section that connects the input and output sides of the power conversion system (Figure 1).

The primary function of the DC link is to store energy during the times when the input power is higher than the output power and release energy when the output power demand exceeds the input power.

The DC link should include a capacitor that servers as a supporting filter to act as a buffer, minimize voltage ripples, and smooth and stabilize the power flow between various components such as rectifiers, inverters, and other converters in the power system.

Capacitors Used on the DC Link

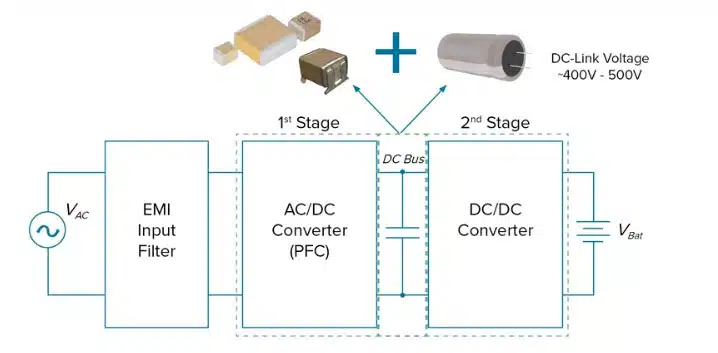

To efficiently operate a power electronics system, it is essential to have large capacitors on the DC link. These capacitors are typically aluminum electrolytic and film capacitors as these options offer high capacitance values and are suitable for energy storage. The key functions of these capacitors include the following:

- Smoothing Ripples: During the power conversion processes there are fluctuations and ripples in the DC voltage output. The large capacitors on the DC link help smooth out these voltage ripples, ensuring a more stable and constant voltage supply to the load.

- Energy Storage: Large capacitors on the DC link act as energy reservoirs, storing surplus energy during periods of low load demand and releasing energy when the load requires additional power. This energy buffering capability enhances the overall efficiency and performance of the power electronics system.

- Surge Suppression: Power electronics systems may encounter voltage surges or transients during switching events or external disturbances. The presence of large capacitors on the DC link enables them to absorb and suppress these voltage surges, protecting sensitive components from damage.

However, relying solely on these large capacitors may not be sufficient for addressing all the requirements of the power electronics system.

To enhance the performance and reliability of the DC link supporting capacitor filter, it is imperative to include ceramic capacitors in the design as well. Ceramic capacitors have unique characteristics that complement the qualities of the aluminum electrolytic and film capacitors nicely including the following:

- Fast Response Time: Ceramic capacitors have significantly faster response times compared to electrolytic and film capacitors. This means ceramic capacitors can efficiently handle high-frequency noise and transients that other capacitors might struggle to address adequately.

- Low Equivalent Series Resistance (ESR) and Equivalent Series Inductance (ESL): The ESR and ESL of ceramic capacitors are much lower than the ESR and ESL of electrolytic capacitors. This results in reduced power losses and improved filtering capabilities.

- Compact Size: Ceramic capacitors offer high capacitance values relative to their compact size. Integrating these capacitors into the DC link supporting capacitor filter allows for efficient space utilization and helps reduce the overall size and weight of the power electronics system.

Helping You Incorporate Ceramic Capacitors as DC Link Supporting Filters

Since Knowles Precision Devices’ engineers have vast experience designing capacitors into both complex and common power electronics systems, we understand that ceramic capacitors are often intuitively added into the final design to support the DC link. This is important because less experienced engineers who may be utilizing reference designs, which don’t always include these extra DC link filters, may not know to design these in – but we can help!