The two most significant contact finish degradation mechanisms are corrosion and wear. While wear is a degradation mechanism, its main effect on connector degradation is to make the contact interface more susceptible to corrosion due to wear through of the contact finish with resultant exposure of the copper alloy contact spring.

Contact Finish Degradation Mechanisms in Connectors

This article explores the degradation mechanisms affecting contact finishes in connectors, focusing on wear and corrosion. It examines the impact of mating cycles and fretting on connector performance, particularly highlighting the role of fretting corrosion in tin contact finishes. Additionally, the paper discusses the corrosion mechanisms affecting noble metal finishes, emphasizing the differences in susceptibility and degradation processes between noble and non-noble metals.

Introduction:

Connectors are critical components in electronic systems, and their performance is significantly influenced by the integrity of their contact finishes. Over time, these finishes can degrade due to various wear and corrosion mechanisms, leading to reduced reliability and functionality. Understanding these degradation processes is essential for improving connector design and longevity.

Wear Mechanisms:

- Mating Cycle Wear:

- Connectors undergo multiple mating cycles during their application lifetime, leading to wear through the finish. This wear is primarily due to the sliding motion between the contact surfaces, which can be extensive due to the larger sliding distances involved.

- Fretting Wear:

- Fretting is a wear mechanism caused by small, repetitive motions at the contact interface, often induced by mechanical or thermally generated stresses. These motions, ranging from fractions of a micron to a few microns, can occur even when the connector is not in use.

- Despite the smaller sliding distances compared to mating cycles, the frequency of fretting cycles can be significantly higher, making fretting wear a critical factor in connector degradation.

- Fretting wear often leads to fretting corrosion, particularly in tin contact finishes, which is a primary degradation mechanism.

Corrosion Mechanisms:

- Fretting Corrosion in Tin Finishes:

- Fretting corrosion occurs when fretting wear exposes the underlying metal, leading to oxidation and corrosion. This process is particularly prevalent in tin contact finishes, where the exposed tin reacts with environmental elements to form corrosion products.

- Corrosion in Noble Metal Finishes:

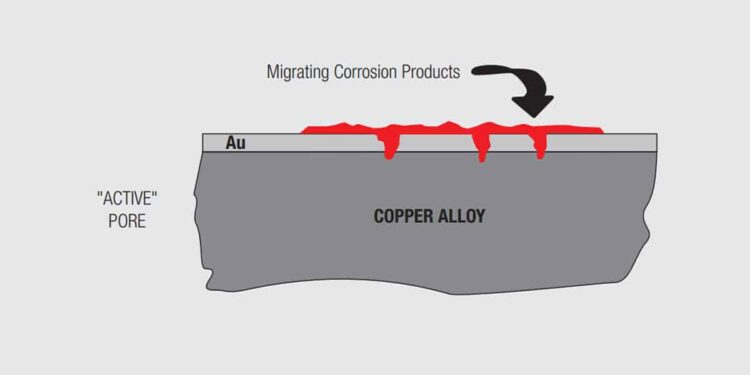

- Noble metal finishes, such as gold, are generally resistant to corrosion in most environments. However, corrosion can still occur due to the exposure of underlying metals like copper from the contact spring.

- The corrosion in noble metal finishes is not due to the noble metal itself but rather the corrosion of the exposed non-noble metal.

Discussion:

The degradation of contact finishes in connectors is a complex process influenced by both wear and corrosion mechanisms. Fretting wear, leading to fretting corrosion, is a significant concern for tin contact finishes, while noble metal finishes experience corrosion primarily due to the exposure of non-noble metals. Understanding these mechanisms is crucial for developing connectors with enhanced durability and performance.

Conclusion:

Addressing the degradation mechanisms of contact finishes is vital for improving connector reliability. By focusing on wear and corrosion processes, particularly fretting wear and corrosion in tin finishes and the exposure of non-noble metals in noble metal finishes, engineers can design connectors that better withstand the challenges of their application environments.