This article based on Samtec blog describe steps how to select the right connector to meet the industry standard protocols.

How to Pick the Right Connector for Your Protocol Requirements

Selecting the proper connector for modern electronic designs is more than matching physical dimensions—it’s about understanding the protocol landscape and ensuring signal performance, reliability, and future scalability.

Step 1: Know Your Protocol’s Signal & Performance Demands

Begin with the protocol at the heart of your system. Each communication standard—such as PCI Express®, Ethernet, USB, or SAS/SATA—dictates unique data rates, signaling types, and integrity thresholds. Make sure to answer:

- What is the maximum data rate your protocol needs (e.g., 28 Gbps, 56 Gbps, 112 Gbps PAM4)?

- Are there specific impedance and crosstalk constraints?

Step 2: Evaluate Connector Signal Integrity Capabilities

A connector’s signal integrity will directly impact protocol reliability. Look for products with proven test results, modeling data, and validation for your target protocol. Compatible connectors should support your bandwidth and maintain low loss and minimal distortion across real-world environments.

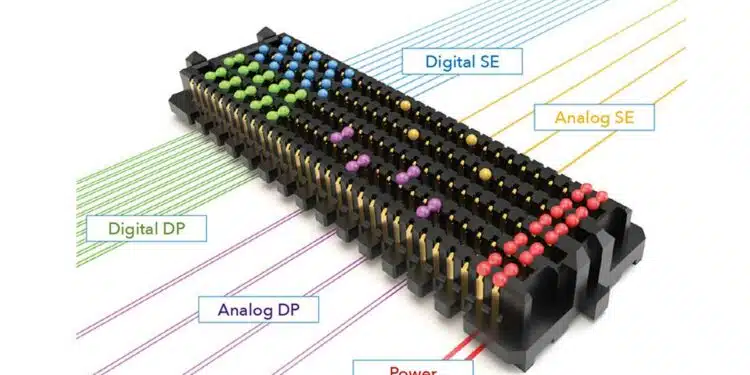

Step 3: Demand Open Pin Field Flexibility

Many high-speed connectors feature open pin fields, enabling designers to define custom differential pair arrangements, ground placement, and power distribution. This flexibility is critical for:

- Supporting multiple protocols (present or future) on the same hardware.

- Optimizing signal routing for EMC and noise reduction.

Step 4: Consider Mechanical & Thermal Constraints

Protocol compliance can only be maintained if the connector matches your application’s mechanical and environmental needs. Consider:

- Required stack height or board-to-board spacing.

- Form factor limitations in compact or ruggedized designs.

- Temperature ratings for mission-critical or industrial systems.

Step 5: Validate with Documentation and Manufacturer Support

Choose connector suppliers who provide access to protocol-specific test data, signal integrity simulation models, and design guides. This accelerates design cycles and boosts confidence in compliance and long-term reliability.

Step 6: Future-Proof Your Design for Multiple Protocols

Modern systems often require support for more than one standard. Select connector platforms that are protocol agnostic, allowing easy upgrades or changes with minimal redesign. This approach enables:

- Smoother transitions to new generations (e.g., PCIe Gen 4 to Gen 5).

- Integration across different architectures or system requirements.

- Scalability as bandwidth and signaling demands grow.

Key Takeaways for Protocol-Focused Connector Selection:

- Start with your protocol’s performance needs—signal speed and integrity set the baseline.

- Seek open pin field designs for maximum flexibility.

- Validate mechanical and environmental compatibility for reliable operation.

- Leverage documentation and supplier resources for simplified testing and compliance.

- Plan for scalability by selecting protocol-agnostic connectors supporting future upgrades.

By following these steps, engineers can confidently select connectors that propel system performance, meet strict protocol requirements, and adapt to future communication challenges.