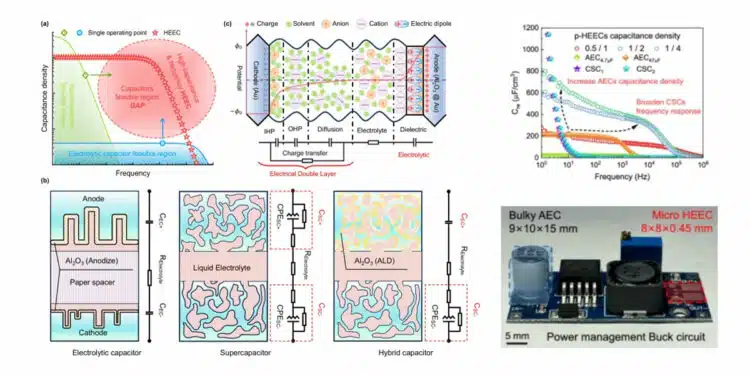

This article published in Nature Communications Journal discusses advancements in high-frequency capacitors development by combining EDLC supercapacitors with electrolytic capacitors, addressing the limitations imposed by slow ion dynamics in traditional electrochemical supercapacitors.

Researchers developed a Hybrid Electrochemical Electrolytic Capacitor (HEEC) that combines electrochemical and dielectric effects to achieve both high capacitance and broad frequency range performance.

The design features a thin dielectric layer and perfect conducting electrodes with mesopores, enabling high characteristic frequency and stable volume capacitance density.

Key points:

- Challenge: Traditional electrochemical supercapacitors suffer from poor frequency response due to the electrical double layer effect, limiting their characteristic frequency.

- Innovation: The HEEC design integrates monolayer graphene as a working electrode and introduces a hybrid approach to enhance both capacitance and frequency response.

- Results: The device achieved a characteristic frequency of 44 kHz with a volume capacitance density of 800 µF/cm³, outperforming conventional electrolytic capacitors in miniaturized electronic systems.

- Applications: The HEEC was successfully integrated into microsystem power management, demonstrating significant size reduction while maintaining performance comparable to commercial capacitors.

The HEEC design combines the advantages of both electrochemical and dielectric effects, providing high capacitance density at low frequencies and extending the frequency range to surpass 10 kHz. A planar micro HEEC with a characteristic frequency of 44 kHz and a stable volume capacitance density of 800 μF/cm3 was fabricated using a selective atomic layer deposition technique.

Hybrid Electrochemical Electrolytic Capacitors (HEECs) combine the high-frequency performance of electrolytic capacitors with the high capacitance of supercapacitors. The design features interdigital electrodes with different widths to balance capacitance density and a parallel circuit layout to enhance frequency response. The HEECs are fabricated using standard semiconductor processes, including lithography, PVD, ALD, and metal lift-off, and demonstrate improved performance compared to traditional hybrid capacitors.

A hybrid electrochemical energy capacitor (HEEC) is fabricated using a CMOS-compatible process, enabling wafer-level production and circuit integration. The HEEC exhibits a porous Au cathode and an Al2O3 dielectric layer on the anode, resulting in a high characteristic frequency exceeding 1 MHz and a capacitance density of 600 μF/cm3 at low frequencies. This performance surpasses commercial electrolytic, ceramic, tantalum, and film capacitors, making it suitable for high-frequency applications.

Parallel-connected HEECs (p-HEECs) are designed to improve high-frequency performance by doubling capacitance density and reducing ESR. Simulation and experimental results show a near-ideal fit, with p-HEECs exhibiting a higher characteristic frequency and lower dissipation factor compared to s-HEECs and commercial capacitors. p-HEECs demonstrate superior high-frequency capacitive behavior, outperforming commercial supercapacitors and bridging the gap between supercapacitors and aluminum capacitors (AEC) in terms of frequency response and capacitance density.

A Hybrid Electrochemical Electrolytic Capacitor (HEEC) design is presented, combining electrolytic and electrochemical capacitors to achieve a 44 kHz characteristic frequency and 800 μF/cm3 volume capacitance density. The HEEC is integrated into a compact power module and a buck circuit, demonstrating its practical utility in power management applications. The HEEC’s potential to revolutionize high-frequency power management for portable electronics is evident.

HEECs are fabricated using wafer-level CMOS-compatible processes, ensuring mass production and chip integration. The fabrication involves depositing electrodes, etching, and applying a gel electrolyte. The capacitance density and dissipation factor of HEECs are calculated based on impedance spectroscopy data, and equivalent circuit simulations are performed using ZView software.

AECs and Conventional SCs are directly purchased from different manufacturers. AECs are tested with the same equipment as HEECs under the same circumstances. The data availability and references are provided.

High-frequency supercapacitors surpassing the dynamic limit of electrical double layer effects are demonstrated. The supercapacitors, based on a hybrid structure of carbon nano-onion and graphene, exhibit ultrahigh-rate performance and are suitable for compact alternating current filtering. The research highlights the potential of these supercapacitors for advanced energy storage applications.

Discussion

This research initiates a great span bridge between commercial electrolytic and electrochemical capacitors, which meets requirements for micro capacitors operating at over kilohertz frequencies, filling the blank of this frequency region in the Ragone Plot. The Hybrid Electrochemical Electrolytic Capacitor (HEEC) design successfully overcomes the frequency limitations of micro capacitors, achieving an impressive 44 kHz characteristic frequency with 800 μF/cm3

volume capacitance density by hybrid incorporation of electrolytic and electrochemical capacitors at the circuit level. By integrating the HEEC into a compact power module and replacing the commercial AEC in the buck circuit, we demonstrate its practical utility in power management applications. The HEEC’s potential to revolutionize high-frequency power management for portable and integratable electronics is evident, offering a promising pathway for more efficient and compact microelectronic devices.

This breakthrough in capacitor design holds potential for future miniaturized electronics, enabling more efficient power solutions for wearable and portable devices.

Read the full original paper:

Li, Z., Xu, M., Xia, Y. et al. High-frequency supercapacitors surpassing dynamic limit of electrical double layer effects. Nat Commun 16, 3704 (2025). https://doi.org/10.1038/s41467-025-59015-7