Littelfuse has introduced two new omnipolar TMR magnetic switches, LF21173TMR and LF21177TMR, targeting space‑constrained, battery‑powered electronics that need precise, low‑power magnetic sensing.

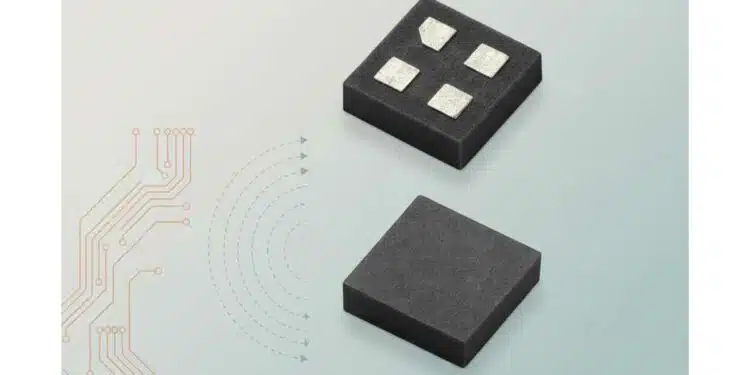

The devices combine Tunneling Magnetoresistance (TMR) and CMOS in a compact LGA4 package to deliver very low current consumption, high sensitivity and fast response over a wide supply range.

Key features and benefits

These Littelfuse switches are designed as general‑purpose digital magnetic switches for smart, battery‑powered systems where every microamp and every square millimeter of PCB area matters.

- Ultra‑low power consumption helps extend battery life in portable and IoT devices that must operate for years on primary cells or small rechargeable packs.

- High magnetic sensitivity in the range of approximately 9–30 Gauss enables reliable switching with smaller or more distant magnets, which simplifies mechanical design and allows thinner enclosures.

- Wide 1.8 V–5.5 V operating voltage range makes the same device suitable from deeply duty‑cycled coin‑cell designs up to 5 V logic and microcontroller rails in industrial electronics.

- Fast response time supports real‑time position, proximity or speed sensing without adding latency in control loops.

- Compact LGA4 package with low profile is well suited for dense multi‑layer boards, flex circuits and miniaturized medical or consumer devices.

- Omnipolar operation detects both north and south poles, eliminating magnet polarity constraints and reducing assembly errors.

- CMOS‑compatible output simplifies direct interfacing to low‑power logic and microcontroller inputs without additional level shifting.

From a magnetic sensor selection perspective, the combination of omnipolar behavior, high sensitivity and ultra‑low current places these parts between the simplest Hall switches and more complex linear or angle sensors, offering a straightforward, digital on/off output with significantly lower power than typical Hall‑effect switches.

Typical applications

The LF21173TMR and LF21177TMR are aimed at a broad set of low‑power, embedded sensing tasks where contactless switching is preferable to mechanical switches or optical interrupters.

- Health care and medical disposables

- Continuous glucose monitors, drug delivery pens and other wearables that require miniature, sealed, low‑current magnetic triggers.

- Building automation and metering

- Smart gas and water meters, particularly battery‑powered endpoints where ultra‑low quiescent current and long service life are critical.

- Consumer and home appliances

- Robotic cleaners, small appliances and portable consumer devices using magnetic switches for lid/door detection, docking detection, or position feedback.

- Industrial automation and access control

- Electronic locks, position sensing in compact actuators and industrial controls operating from 3.3 V or 5 V rails.

- Light electric and off‑highway vehicles

- E‑bike and small vehicle systems for position or proximity sensing in throttles, levers or encoders where robust, non‑contact operation is needed.

For engineers currently using unipolar or bipolar Hall switches in these segments, the new devices can offer reduced current draw and greater sensitivity while simplifying magnet orientation constraints during mechanical design.

Technical highlights

The key differentiator of the LF21173TMR and LF21177TMR is their use of TMR technology in a simple switch configuration.

- TMR sensing principle

- TMR devices measure the change in electrical resistance of magnetic tunnel junctions when exposed to a magnetic field, generating a stronger electrical signal at lower bias current than traditional Hall‑effect devices.

- This leads to better signal‑to‑noise ratio and accuracy at very low current, which is particularly important across temperature and over long lifetimes in sealed systems.

- Omnipolar switching

- The devices assert their output when either a north or south magnetic pole exceeds the defined operate threshold and release when the field falls below the release threshold.

- Omnipolar behavior reduces the need to control magnet polarity and can simplify both assembly instructions and quality control.

- Electrical characteristics (high‑level)

- Supply voltage: 1.8 V to 5.5 V, covering typical MCU and logic rails as well as coin‑cell operating ranges with regulators or direct connection according to the manufacturer datasheet.

- Sensitivity: operate thresholds around 9–30 Gauss, depending on the specific part and configuration, allowing the use of relatively small, low‑cost magnets.

- CMOS output interface designed for direct connection to low‑power logic inputs; detailed timing, current and output characteristics should be taken from the manufacturer datasheets.

The LGA4 package offers a very small footprint and low height, which may require careful PCB land pattern design and assembly process control, but allows dense placement close to moving magnets or in narrow housings.

Design‑in notes for engineers

When designing with omnipolar TMR switches such as LF21173TMR and LF21177TMR, a few practical considerations can help ensure robust performance and manufacturability.

- Magnet selection and placement

- Take advantage of the high sensitivity to minimize magnet size, but verify operate/release margins across mechanical tolerances, temperature and aging.

- Because the devices are omnipolar, focus on consistent field strength and air‑gap rather than magnet polarity, which can simplify magnet sourcing and assembly orientation.

- Power budget and duty cycling

- Ultra‑low current draw makes these switches good candidates for always‑on sensing in battery‑powered nodes, without aggressive duty cycling.

- In systems where the microcontroller sleeps deeply, the TMR switch can provide a wake‑up signal while consuming far less current than the main MCU or RF section.

- PCB layout and assembly

- The small LGA4 footprint requires accurate PCB manufacturing and placement; pay attention to recommended land patterns, solder mask openings and reflow profiles from the datasheet.

- Keep high‑current traces and noisy switching nodes away from the device to avoid unintended magnetic interference in sensitive applications.

- System‑level robustness

- Validate switching thresholds in the full mechanical assembly (enclosure closed, magnets in final location) rather than only on open PCBs.

- In safety‑critical applications (locks, medical dosing), consider redundant sensors or plausibility checks in firmware to detect stuck‑on or stuck‑off conditions.

- Interfacing to logic

- Use the CMOS output directly with microcontroller GPIO configured with appropriate pull‑ups or pull‑downs as recommended; check absolute maximum ratings for any external pull resistors.

- For noisy or long signal runs, simple RC filtering or debounce in firmware may improve robustness without adding significant delay.

Positioning these TMR switches early in the architecture phase can help optimize enclosure size, magnet cost, and overall power budget compared to legacy Hall‑effect switch designs.

Source

This article is based on information published by Littelfuse in its official press release announcing the LF21173TMR and LF21177TMR omnipolar TMR magnetic switches and related product documentation, with additional neutral technical commentary and design‑in guidance for engineers and component specifiers.