source: Murata news

Murata Manufacturing Co., Ltd. has expanded the RHS Series of lead type multilayer ceramic capacitors for automotive use in high temperature applications. Products newly introduced at this time include a 100Vdc rated product for 200°C use, which expands the previous lineup of 200Vdc and 500Vdc products, and a 100Vdc rated product for 175°C use with high capacitance. These products are primarily meant for use in equipment located in severe temperature environments such as the engine compartment of an automobile. The 100Vdc rated product for 200°C will begin mass production at Iwami Murata Manufacturing Co., Ltd. in January 2018, and the 100Vdc rated product for 175°C will begin in February 2018. Samples are available for ¥200.

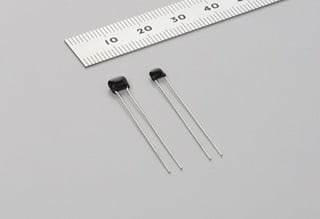

A power train control system uses a DC motor drive to increase control in order to improve the fuel economy of an automobile. A capacitor is used to suppress the electrical noise generated by this DC motor. The automobile control equipment is mounted in an extreme environment, where temperatures can approach 200°C for short periods of time. A high degree of durability is needed for a capacitor that is implemented in this environment. This series from Murata applies a coating of newly developed heat resistant resin around a highly heat resistant multilayer ceramic capacitor, allowing use at a 200°C maximum temperature. The previous products with rated voltage of 200Vdc and 500Vdc had capacitance of 0.01μF, but the newly added 100Vdc product for 175°C and 200°C offers a smaller size and expands capacitance up to 0.1µF. The company expects to expand sales of products for equipment mounted in high temperature environments such as engine compartments.

Features

- Lead wire type capacitor can be connected by welding or “crimping*1” close to a noise generating source.

- Complies with AEC-Q200*2

- Passes the extreme surge test of the ISO7637-2*3 standard.

Detailed specification

| Operating temperature range | -55 to 175°C | -55 to 200°C |

| Rated Voltage |

100Vdc

(Rated voltage at 175°C is reduced to 50%)

|

100Vdc

(temperature characteristics code: 7G) 200Vdc、500Vdc (temperature characteristics code: 7J) (Rated voltage at 200°C is reduced to 25%)

|

| Capacitance and temperature characteristics Or Temperature Coefficient (ppm/°C) |

Temperature characteristics code:L1

-55 to 175°C:+15/-40%

Temperature characteristics code:N1

-55 to 175°C:+15/-60%

|

Temperature characteristics code:7G

-55 to 25°C :0 +30/-72ppm/°C

25 to 125°C :0 +/-30ppm/°C

125 to 200°C:0 +72/-30ppm/°C

Temperature characteristics code:7J

-55 to 25°C :-750 +120/-347ppm/°C

25 to 125°C :-750 +/-120ppm/°C

125 to 200°C:-750 +347/-120ppm/°C

|

| Capacitance range |

Temperature characteristics code:L1 Temperature characteristics code:N1 |

Temperature characteristics code:7G Temperature characteristics code:7J |

| Dimensions (L×W) |

Size0:3.8×3.5mm max Size1:4.0×3.5mm max Size2:5.5×4.0mm max |

|

External dimensions and lead wire pitch

| L×W: | Determined by the combination of rated voltage and electrostatic capacity. |

| F(lead wire pitch): | For 100Vdc and 200Vdc rated products, this can be selected from either 2.5mm or 5.0mm. For 500Vdc products, this is 5.0mm. |

About voltage/temperature derating

When product temperature exceeds 150°C, reduce the voltage to be applied to the capacitor in correlation to the rated voltage shown below.

Explanation of terms

*1. Crimping:A metal component or fitting is fastened using a pliers or custom tool without using an adhesive.

*2. AEC-Q200:Test standards for reliability sought in automobile electrical parts, as decided by the Automotive Electronics Council.

*3. ISO7637-2:Test standards for checking durability against noise generated by automobile electrical equipment.